Low-temperature sintering near-zero resonance frequency temperature coefficient cadmium tungstate-based composite ceramics and preparation method thereof

A technology of composite ceramics and resonant frequency, applied in the field of near-zero resonant frequency temperature coefficient cadmium tungstate-based composite ceramics and its preparation, can solve the problem of high sintering temperature and achieve excellent microwave dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] To prepare cadmium tungstate based composite ceramics 0.80CdWO 4 -0.20TiO 2 For example, the materials used and the preparation method are as follows:

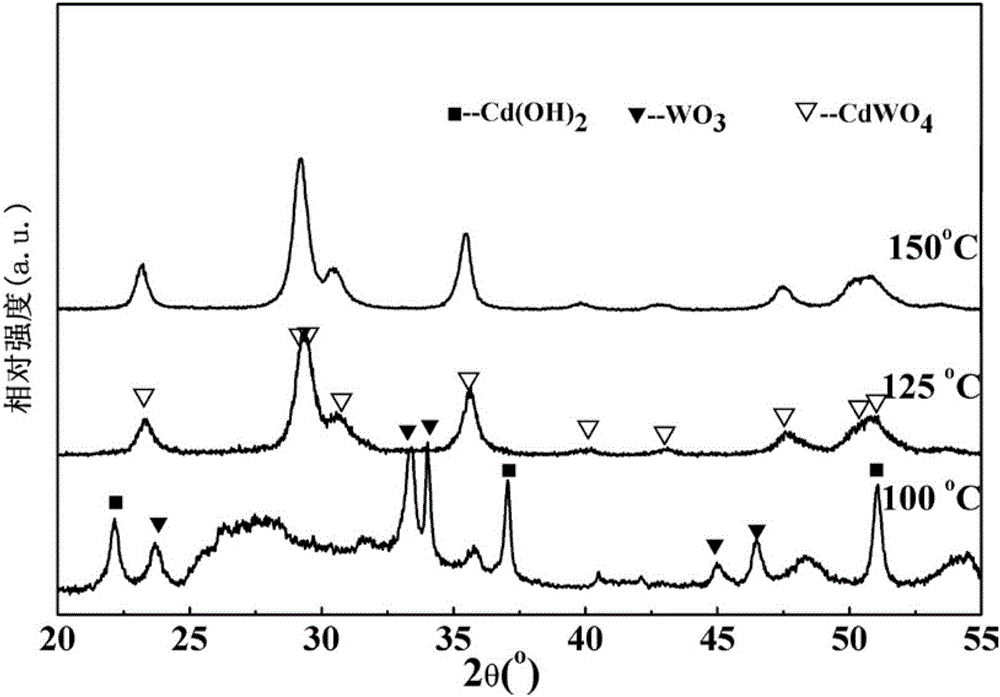

[0021] 1. Preparation of CdWO 4 Burnt powder

[0022] According to CdWO 4 The stoichiometric ratio of raw materials CdO (purity>99.0%) 10.6931g, WO 3 (Purity>99.0%) 19.3069g is put into a tungsten carbide ball mill jar with an inner diameter of 80mm, and then add 2 tungsten carbide balls with a diameter of 20mm, 8 tungsten carbide balls with a diameter of 10mm and several tungsten carbide balls with a diameter of 5mm, the total mass of tungsten carbide balls 450g, using Pulverisette4 planetary high-energy ball mill for ball milling, the revolution speed is 300 revolutions per minute, the rotation speed is 450 revolutions per minute, and the rotation direction is opposite to the revolution direction. Stop cooling for 30 minutes after every 1 hour of ball milling, the total ball milling time is 30 hours, and the mixt...

Embodiment 2

[0028] In step 2 of Example 1, after the green body is kept at 500°C for 2 hours, the temperature is raised to 925°C for 3 hours, and then the temperature is lowered with the furnace. The other steps are the same as in Example 1 to make cadmium tungstate-based composite ceramics .

Embodiment 3

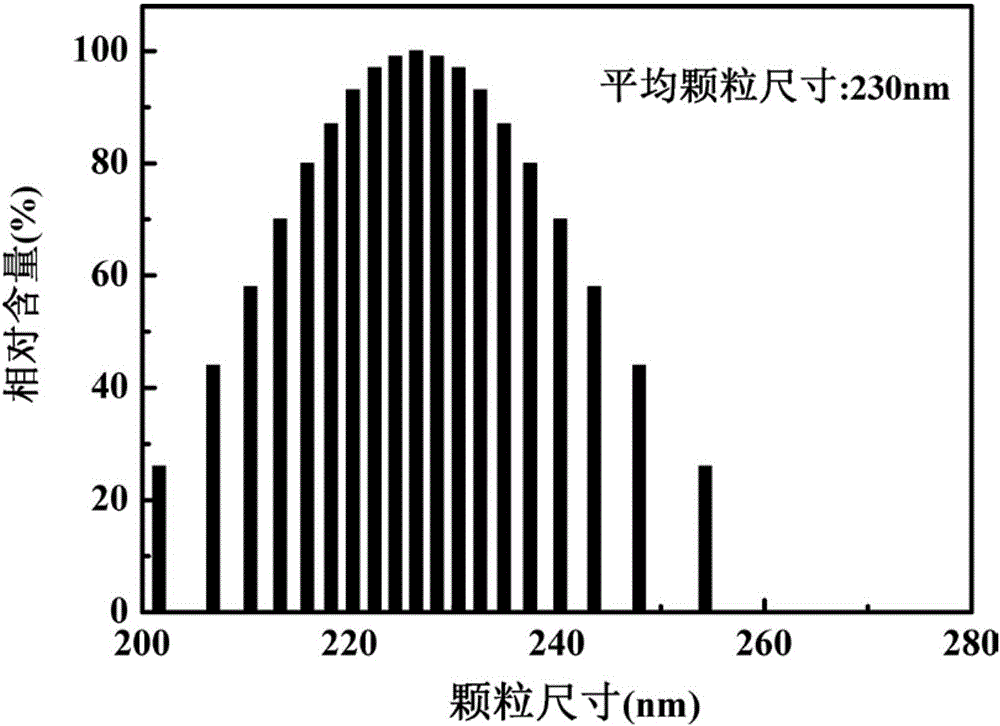

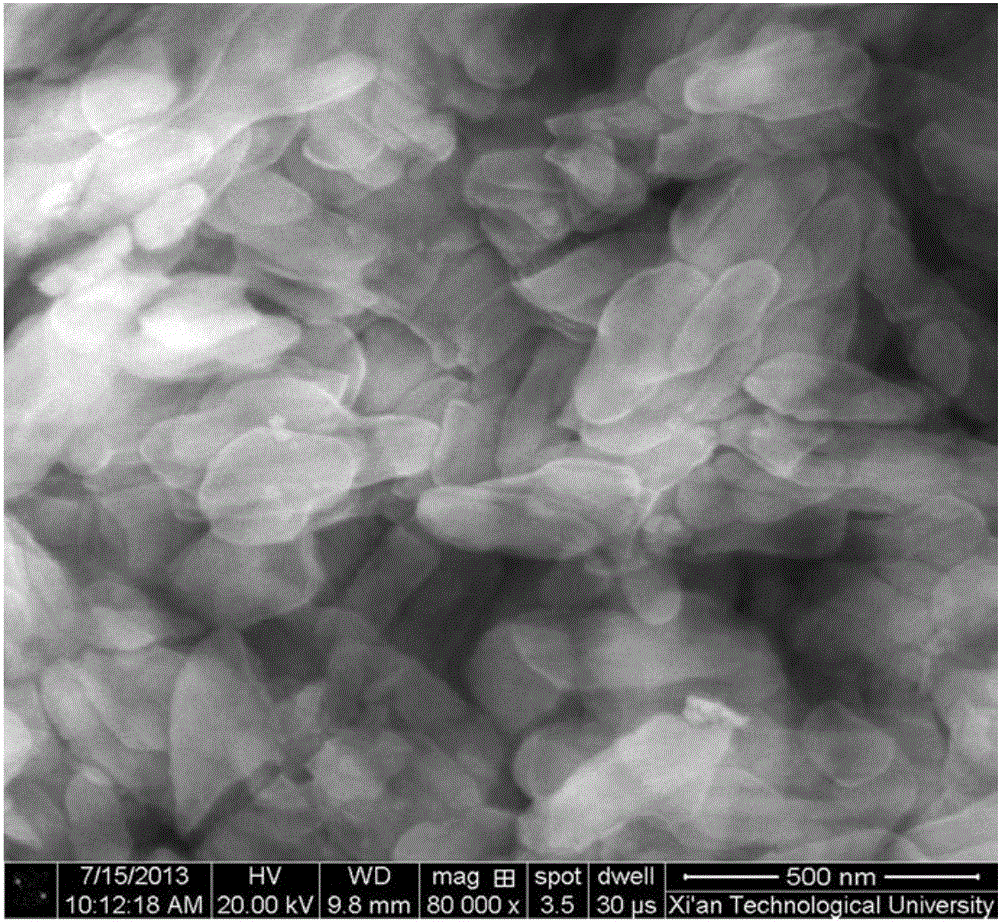

[0030] To prepare cadmium tungstate based composite ceramics 0.79CdWO 4 -0.21TiO 2 For example, the materials used and the preparation method are as follows:

[0031] Prepare CdWO according to step 1 of Example 1 4 Burnt powder. In step 2 of preparing cadmium tungstate-based composite ceramics, according to 0.79CdWO 4 -0.21TiO 2 The stoichiometric ratio of the raw material CdWO was weighed 4 Calcined powder 23.0000g and rutile phase TiO with a particle size of 30-60nm 2 1. 3560g, put into a polytetrafluoroethylene ball mill jar, use absolute ethanol as the ball milling medium, mill with agate balls for 5 hours, then dry at 70-80°C for 10 hours, add 5%-10% of the mass fraction of raw materials It is a 5% polyvinyl alcohol aqueous solution, granulated, passed through a 120 mesh sieve, left to stand at room temperature for 24 hours, and made into a cylindrical raw material with a diameter of 11.5 mm and a thickness of 5 to 6 mm with a powder tablet press under a pressure of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com