Method for regulating phase-transition temperature of vanadium dioxide film

A technology of vanadium dioxide and phase change temperature, applied in the field of functional materials, can solve problems such as complex operation, small adjustment range, and poor process repeatability, and achieve the effects of low phase change temperature, large adjustment range, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

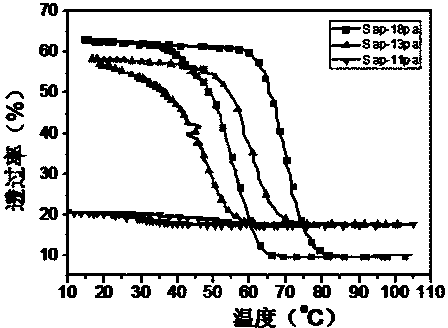

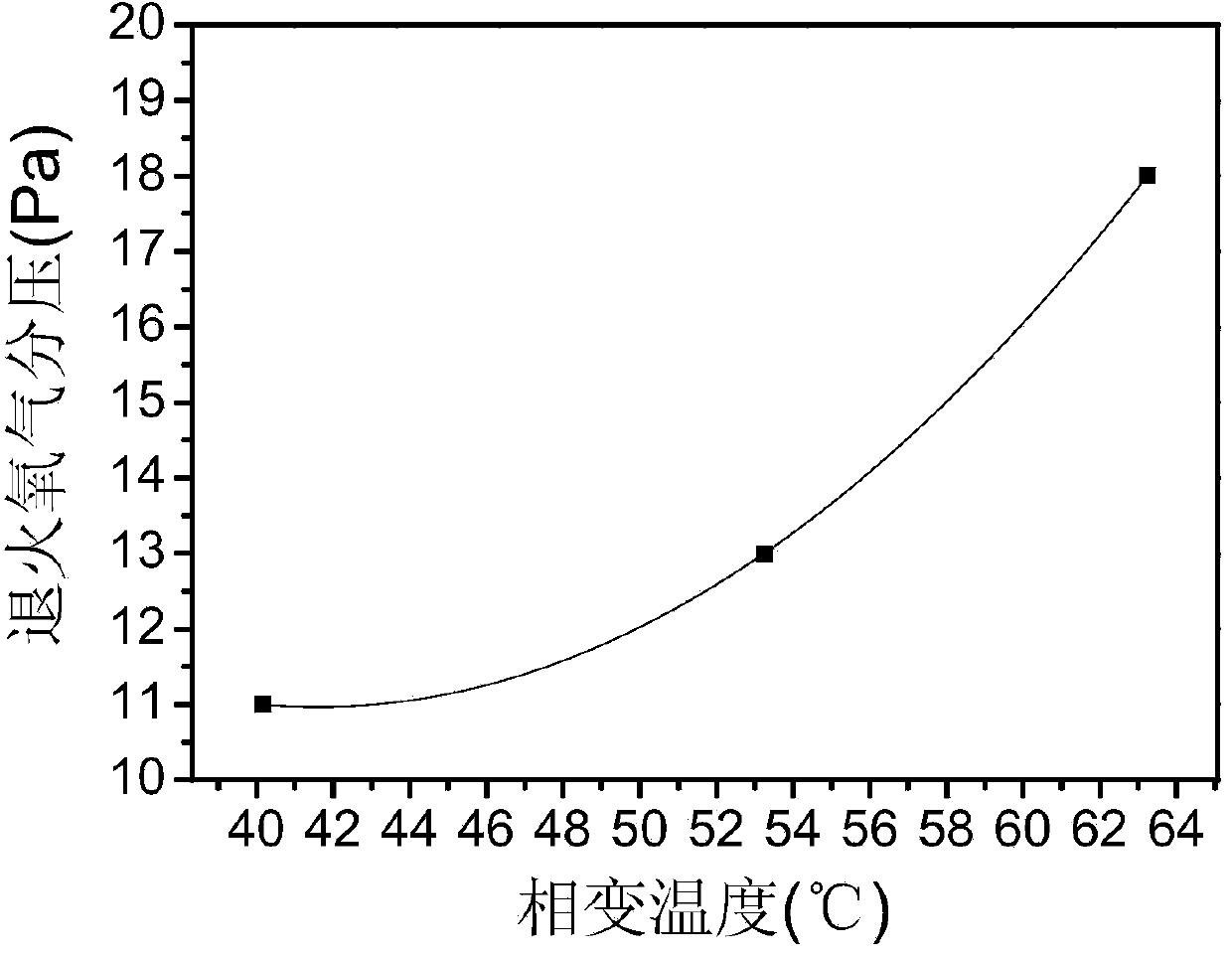

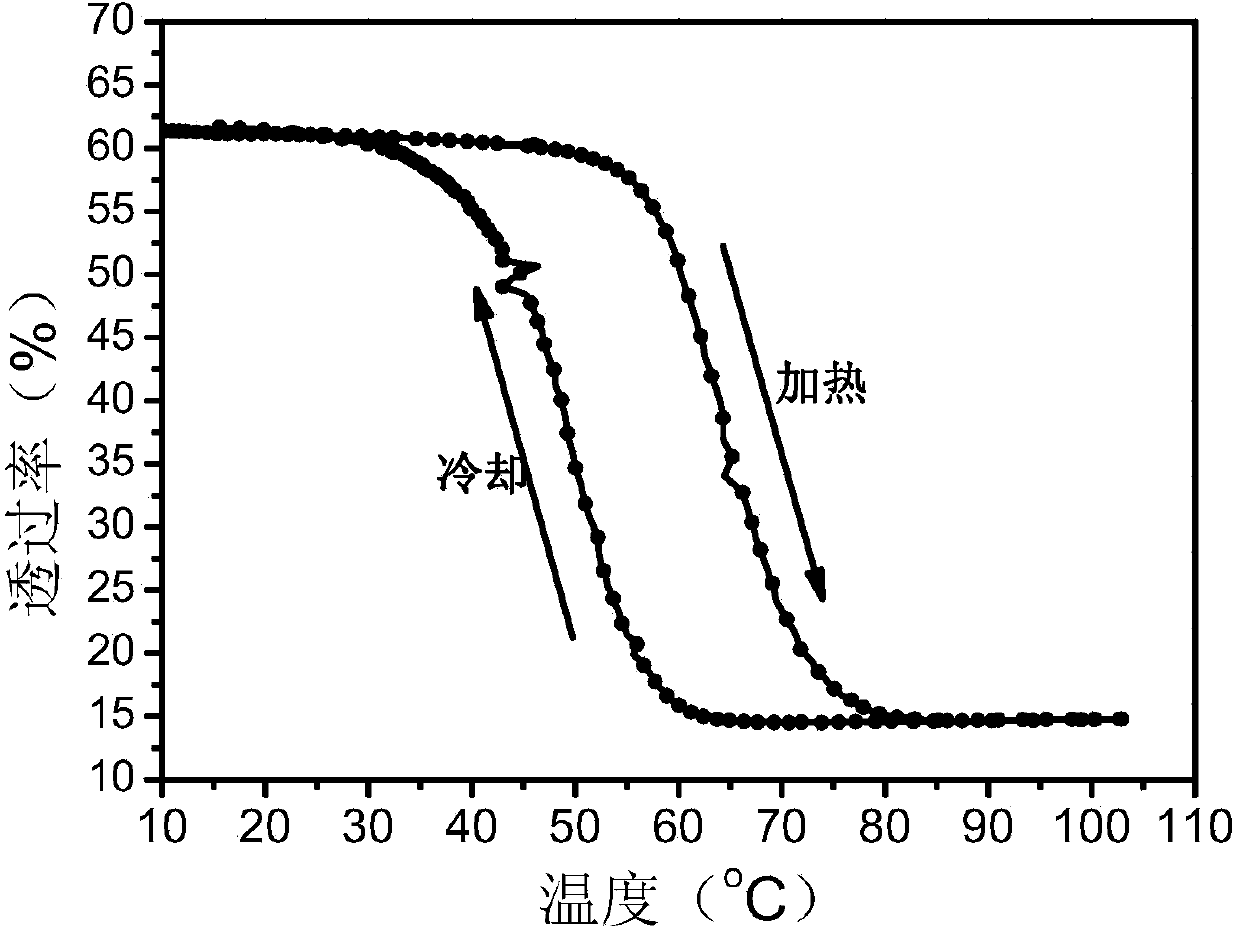

[0035] In this example, sapphire is used as a substrate, and a metal vanadium film is plated on its surface, then annealed in a vacuum tube annealing furnace to form a vanadium dioxide film, and then the performance of the film is tested. The specific implementation steps are as follows:

[0036] 1. Substrate cleaning. Put the sapphire in alcohol and ultrasonic for 10 minutes to remove the oil stain on the surface of the substrate. After the ultrasonic cleaning, quickly take it out, dry it with nitrogen, and put it into the coating chamber.

[0037] 2. Plating 50nm metal vanadium film. The vanadium target used in the coating system is a 320×140mm planar target with a purity of 99.99%. The sputtering process gas is argon with a purity of 99.999%. System base vacuum is 1×10 -3 Pa. Adjust the argon flow rate to 50sccm during sputtering coating, and the system pressure is 0.22Pa at this time; set the sputtering power to 500W, and the sputtering voltage is 338V at this time; t...

Embodiment 2

[0046] In this example, glass is used as a substrate, and a metal vanadium film is plated on its surface, and then annealed in a vacuum tube annealing furnace to form a vanadium dioxide film, and the performance of the film is tested. The specific implementation steps are as follows:

[0047] 1. Substrate cleaning. Put the sapphire in alcohol and ultrasonic for 10 minutes to remove the oil stain on the surface of the substrate. After the ultrasonic cleaning, quickly take it out, dry it with nitrogen, and put it into the coating chamber.

[0048] 2. Plating 50nm metal vanadium film. The vanadium target used in the coating system is a 320×140mm planar target with a purity of 99.99%. The sputtering process gas is argon with a purity of 99.999%. The basic vacuum of the system is 1×10-3Pa. Adjust the argon flow rate to 50sccm during sputtering coating, and the system pressure is 0.22Pa at this time; set the sputtering power to 500W, and the sputtering voltage is 338V at this ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com