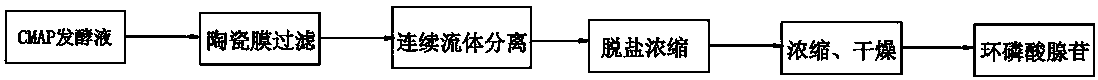

Production process of cyclic adenosine monophosphate

A cyclic adenosine monophosphate, production process technology, applied in the field of production of cyclic adenosine monophosphate, can solve the problems of high cost, large solvent loss, environmental pollution, etc., to increase yield, improve product quality, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

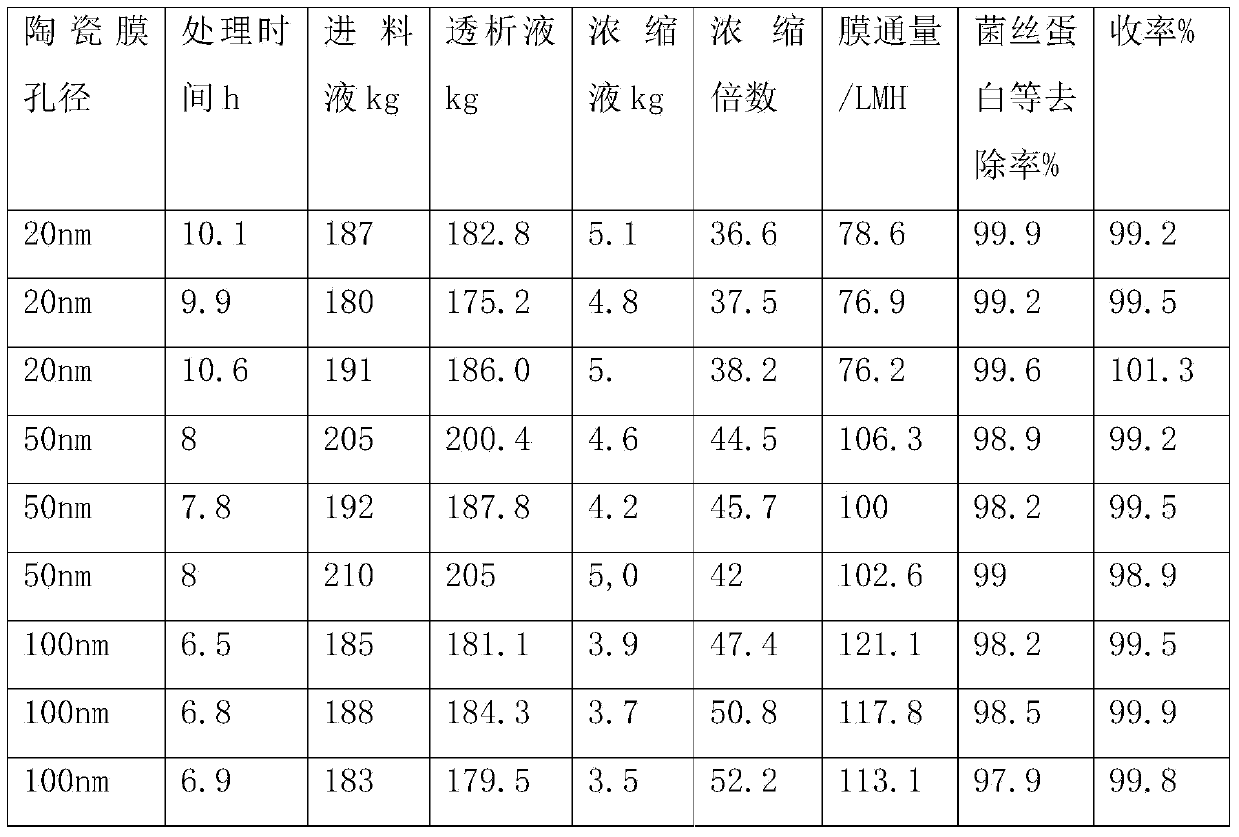

[0029] (1) Step 1 Ceramic membrane filtration to remove impurities: filter the cyclic adenosine monophosphate fermentation broth through ceramic membrane filtration equipment, remove mycelia, suspended matter, colloids and macromolecular organic matter in the filter residue, and obtain the dialysate of the fermentation broth; respectively use 20nm / 50nm / 100nm ceramic membrane system was used to filter the fermentation broth, the temperature was 28°C, the pressure was 0.25Mpa, and two batches of experiments were carried out.

[0030]

[0031] According to the experimental data, the ceramic membrane is used to remove impurities from the fermentation broth, which has the characteristics of large flux, high removal rate of impurities, and less product loss.

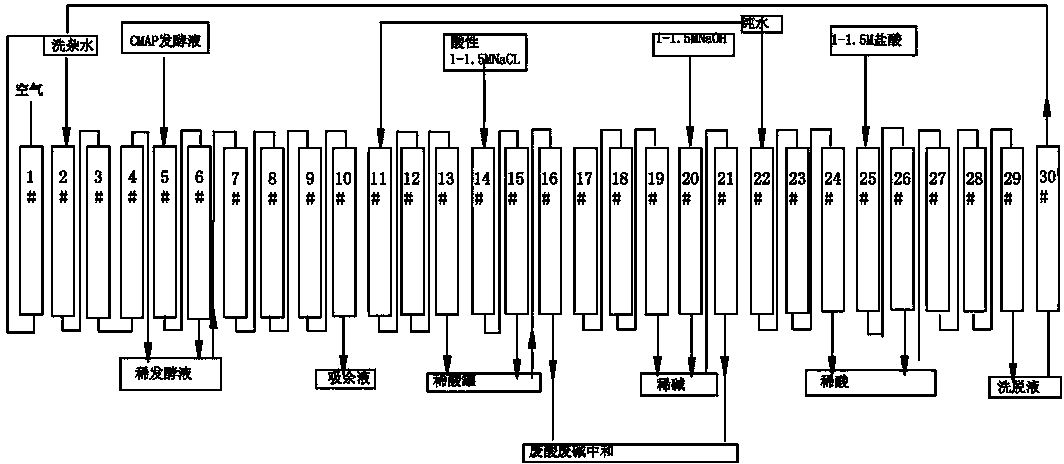

[0032] (2) Step 2 Continuous fluid separation: The continuous fluid separation system has 30 built-in separation units, each separation unit is filled with anion exchange resin, and the 30 separation units are designed as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com