Preparation method of black waterborne polyurethane dye

A technology for water-based polyurethane and black dye, applied in the field of water-based polyurethane, can solve the problems of low phenolic hydroxyl activity, uncontrollable, limited amount of chromophore access, and achieve high color fastness, good durability, and improved washing resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

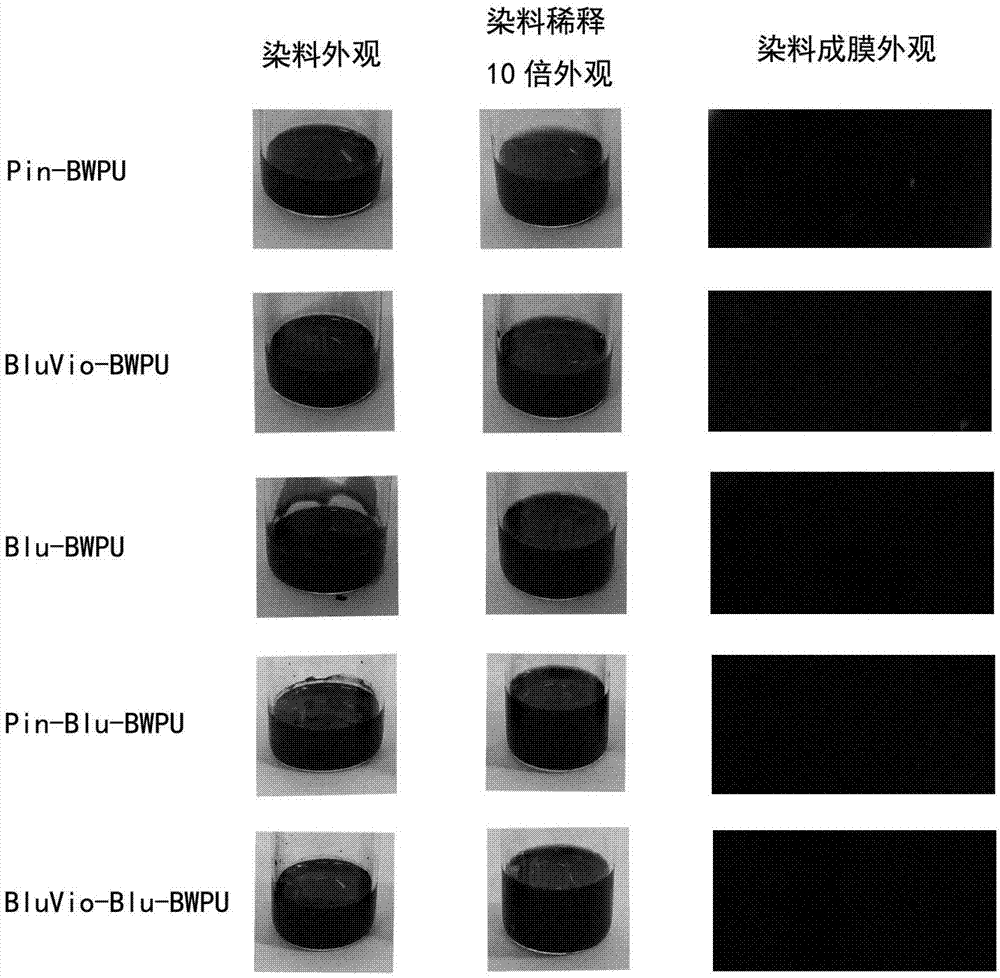

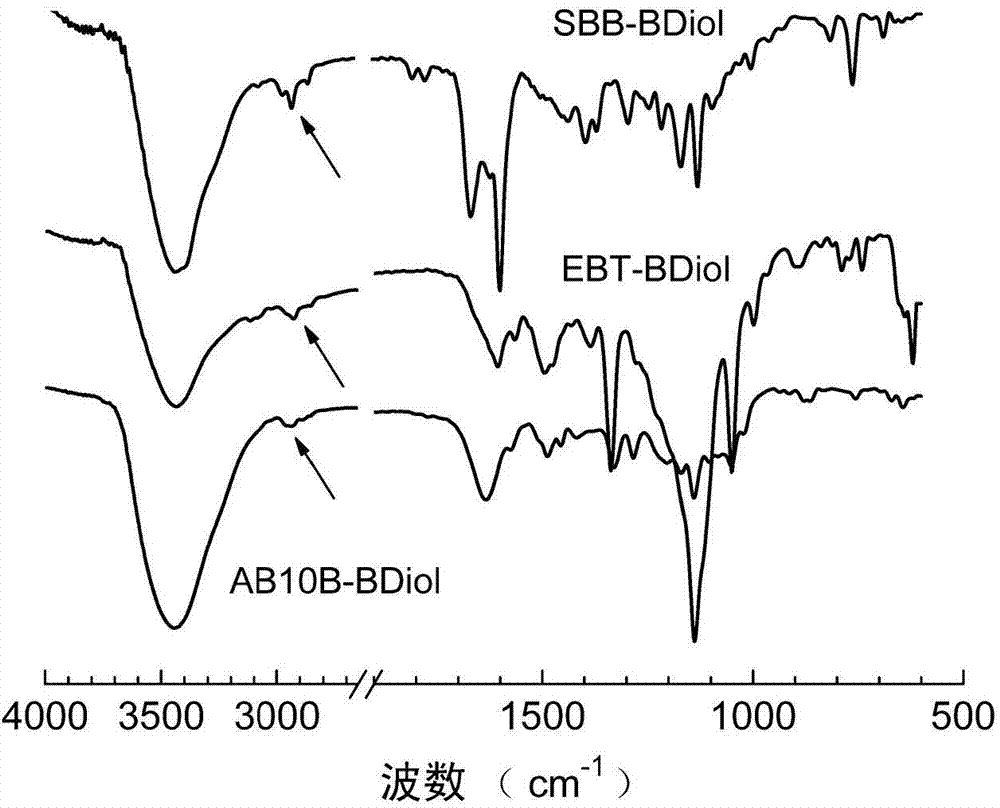

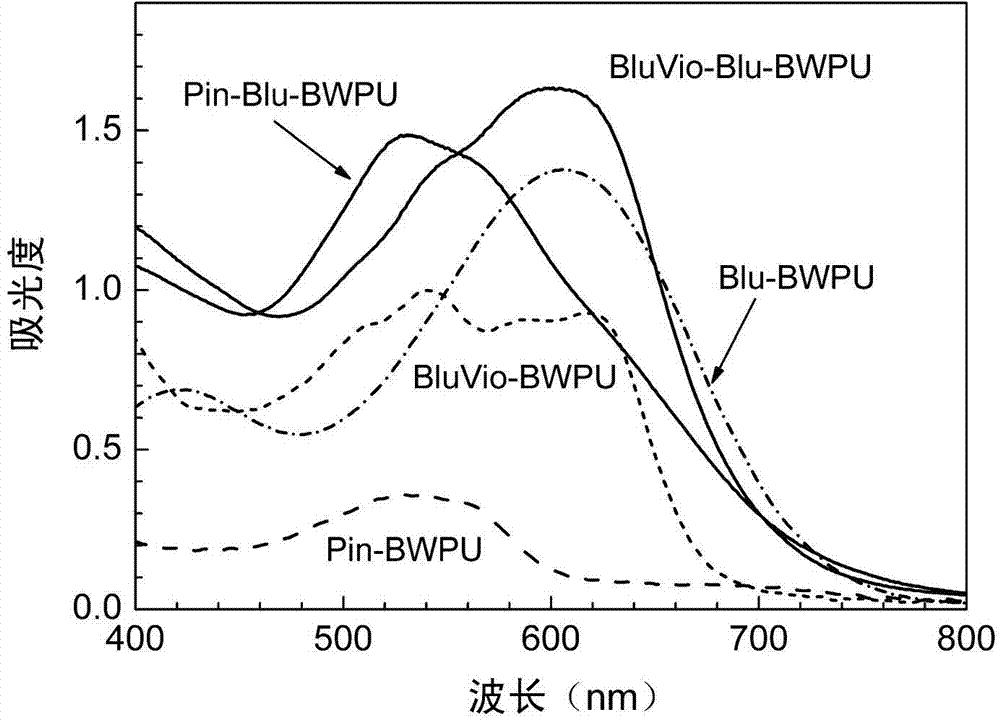

[0034] Add 2.65 grams of chloroethanol, 0.25 grams of sodium hydroxide, 0.05 grams of sodium iodide and 1.21 grams of chrome black T into 70 milliliters of water, and keep it at 90 °C for 12 hours after completely dissolving, and slowly add 1.5 milliliters of mass percent to the reaction system Concentrated hydrochloric acid with a concentration of 37%; after the reaction, remove 70% of the added water at 60°C and 0.01MPa vacuum, and the filtered precipitate is washed with 10ml of water and dried in a vacuum oven to constant weight to obtain black Solid chrome black T-type pink light black diol EBT-BDiol;

[0035] 14 grams of number average molecular weight M n PTMG of 2000 was dehydrated at 110°C for 1 hour, cooled to 50°C, added 7 grams of IPDI, stirred and reacted at 80°C for 2 hours, then added 0.48 grams of EBT-BDiol prepared above, 1.5 grams of DMPA, 0.9 grams of BDO, 0.01 grams of DBTDL and 10 grams of methyl ethyl ketone, the constant temperature was cooled to 20 DEG ...

Embodiment 2

[0046] Add 2.84 grams of chloroethanol, 0.2 grams of sodium hydroxide, 0.05 grams of sodium iodide and 1.25 grams of amino black 10B into 70 ml of water, and keep it at 90°C for 24 hours after being completely dissolved; slowly add 2 ml of mass percent to the reaction system Concentrated hydrochloric acid with a concentration of 37%; after the reaction, 80% of the added water was pumped out under 60°C and 0.01MPa vacuum conditions; the filtered precipitate was washed with 10ml of water and dried in a vacuum oven to constant weight to obtain black Solid amino black 10B type blue violet light black diol AB10B-BDiol;

[0047] 14 grams of number average molecular weight M n PPG of 2000 was dehydrated at 110°C for 1 hour and then cooled to 50°C, added 5.45 grams of TDI, stirred and reacted at 80°C for 2 hours, then added 0.48 grams of the above-prepared AB10B-BDiol, 1.5 grams of DMPA, 1.05 grams of DEG, and 0.01 grams of DBTDL and 10 grams of acetone, stirred and reacted at a cons...

Embodiment 3

[0054] Add 1.3 grams of chloroethanol, 0.25 grams of potassium carbonate, 0.04 grams of sodium iodide and 0.75 grams of Sudan Black B into 70 milliliters of acetone, raise the temperature to 60°C and keep it warm for 18 hours; after the reaction, add 200 milliliters of water to the reaction system until precipitation Precipitation, the filtered precipitate was washed with 20ml of water and then dried in a vacuum oven to constant weight to obtain a black solid Sudan Black B-type blue light black diol SBB-BDiol;

[0055] 14 grams of number average molecular weight M n The PCL of 2000 was dehydrated at 110°C for 1 hour, then cooled to 50°C, added 7 grams of IPDI, stirred and reacted at 80°C for 2 hours, and then added 0.42 grams of the above-prepared SBB-BDiol, 0.4 grams of BDO, 0.01 grams of DBTDL and 10 grams of Acetone, keep the temperature at 70°C for 5 hours and then cool down to 55°C; then add dropwise a mixed solution of 1.9 grams of MDEA and 5 grams of acetone within 2 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com