A polyacrylate pressure sensitive adhesive

A technology of pressure-sensitive adhesives and polyacrylates, applied in the direction of ester copolymer adhesives, adhesive types, etc., can solve the problems of insufficient compatibility with diimonium salt dyes, etc., and achieve good bonding performance and internal High poly strength and good optical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

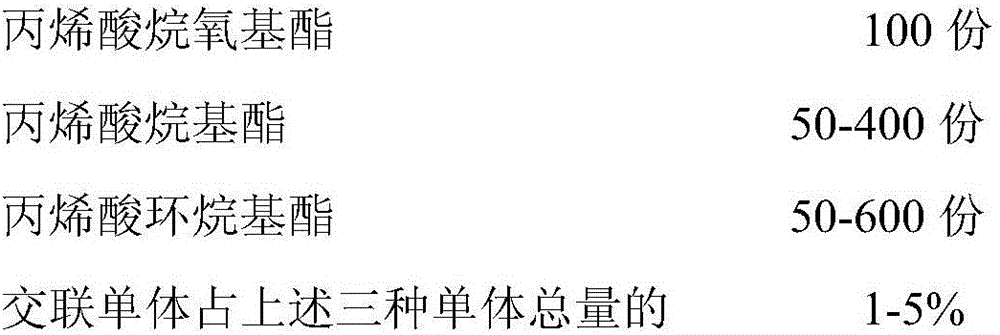

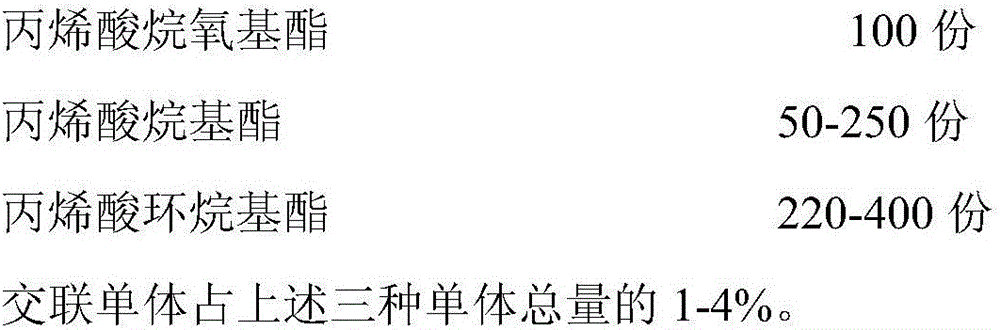

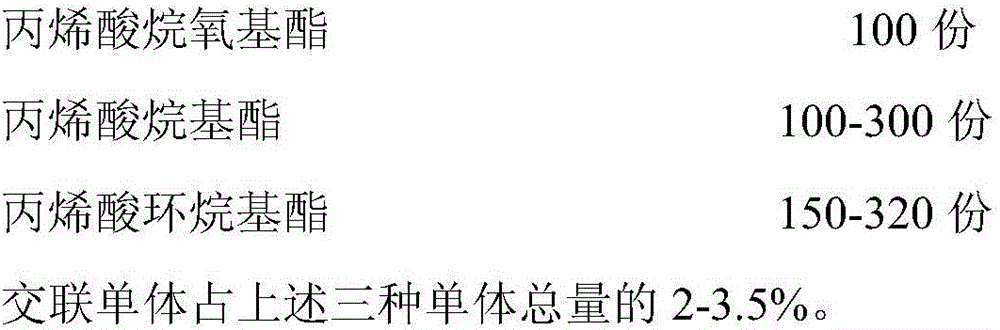

Method used

Image

Examples

Embodiment 1

[0035] In access N 2 In the case of 300 parts of n-butyl acrylate, 100 parts of ethoxyethyl acrylate, 400 parts of cyclohexyl acrylate, acrylic acid accounting for 1% of the total amount of the above-mentioned monomers is proportionally mixed with 1% of the total amount of monomers. Dibenzoyl oxide and 300 parts of ethyl acetate were mixed and added to the reaction flask at one time. Stirring was started and the temperature was raised to 75°C by heating in a water bath, and the reaction was refluxed for 2 hours. The initiator solution consisting of 0.1% dibenzoyl peroxide and 150 parts of ethyl acetate, which accounts for 0.1% of the total amount of monomers, was added dropwise at a constant speed under continuous reflux, and the reflux reaction was continued for 4 hours. Then, the initiator solution consisting of 0.1% dibenzoyl peroxide and 150 parts of ethyl acetate was added dropwise at a constant speed under continuous reflux, and the temperature was raised to 80°C, and t...

Embodiment 2

[0039] The type and proportion of raw materials are adjusted to 50 parts of isooctyl acrylate, 100 parts of methoxyethyl methacrylate, 180 parts of cyclohexyl methacrylate, acrylic acid accounting for 4.2% of the total amount of the above monomers, and the polymerization temperature is changed to 80°C , and the temperature was raised to 85° C. in the later stage, and the rest of the polymerization method was the same as that of Example 1.

[0040] The pressure-sensitive adhesive solution is light yellow and transparent, with a solid content of 34% and a viscosity of 2320 mPa•s.

[0041] After the pressure-sensitive adhesive was mixed with hexafluorophosphate-N,N,N′,N′-tetrakis[p-bis(cyclohexylmethyl)aminophenyl]-p-phenylene diimmonium dye, the dye did not flocculate after one week Precipitation, transmission spectrum change rate 0.6%, peel strength 4.7N / 25mm (relative to optical glass, 180°peel), no adhesive residue on the bonding surface.

Embodiment 3

[0043] The type and proportion of raw materials are adjusted to 300 parts of ethylhexyl acrylate, 100 parts of methoxyethyl acrylate, 600 parts of cyclohexyl acrylate, hydroxypropyl acrylate accounting for 4% of the total amount of the above monomers, and the initiator is azobis Isobutyronitrile, all the other polymerization methods are with embodiment one.

[0044] The pressure-sensitive adhesive solution is colorless and transparent, without gel, with a solid content of 59% and a viscosity of 5120 mPa•s.

[0045] After the pressure-sensitive adhesive was mixed with 4% hexafluorophosphate-N,N,N',N'-tetrakis[p-bis(cyclohexylmethyl)aminophenyl]-p-phenylene diimmonium dye, after one week the dye No flocculation precipitation, transmission spectrum change rate 0.3%, peel strength 3.5N / 25mm (relative to optical glass, 180°peel), no adhesive residue on the bonding surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com