Swida wilsoniana oil extracting method

A light-skinned wood and extraction method technology, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems of destroying oil nutrients, flammability, and difficult utilization of pressed cakes, so as to shorten the extraction time cycle, reduce production costs, and retain nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

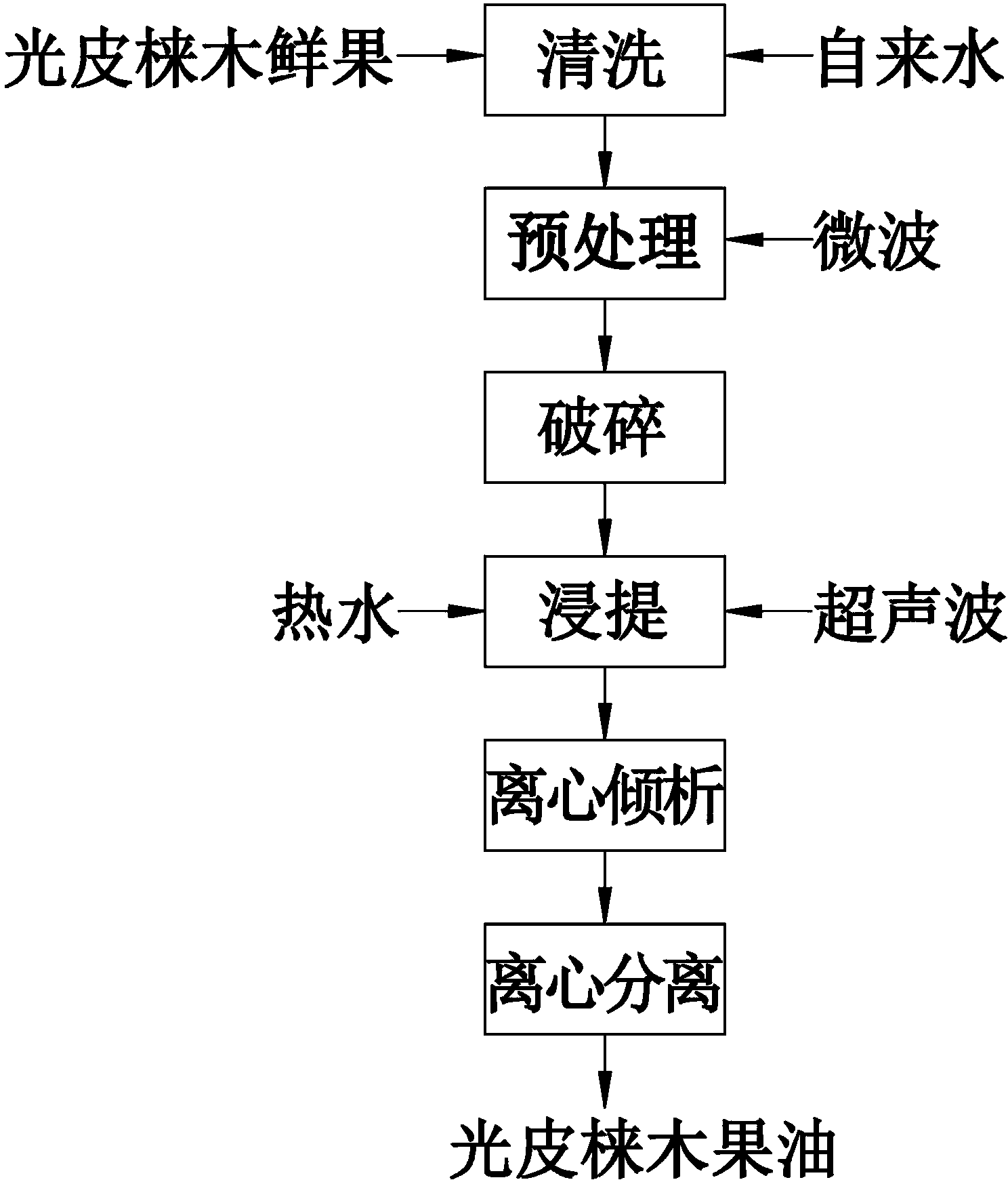

Method used

Image

Examples

Embodiment 1

[0026] In the first step, take 1000g of fresh ashwagandha fruit and wash the fresh ashwagandha fruit twice with tap water to remove impurities such as soil and dust on the surface of fresh ashwagandha fruit;

[0027] The second step is to place the cleaned fresh fruit of ashwagandha in a microwave baking device for microwave baking pretreatment, and the microwave baking is carried out at intervals. After the fresh fruit was taken out and cooled to room temperature, the fresh fruit of ashwagandha was microwaved for 1 min, and the above steps were repeated until the required microwave baking time was accumulated. The microwave power of the microwave baking pretreatment was 400 W, and the microwave baking time was 3 min.

[0028] Microwave energy can penetrate the surface of fresh ashwagandha fruit, causing polar molecules in the fruit to rub against each other to generate internal heat, thereby making the liquid inside the fruit instantly heat up, vaporize, pressurize and expand...

Embodiment 2

[0035] In this embodiment, the similarities with Embodiment 1 will not be repeated, the difference is that, in this embodiment, the microwave power in the microwave baking pretreatment is 800 W, and the microwave baking time is 5 min; The fresh fruit of ashwagandha was broken into pulp, the particle size of the pulp (referring to the stone fragments) was 75 mesh, the ratio of solid to liquid was 1:4.5, the extraction temperature was 60 °C, the time of ultrasonic-assisted extraction was 40 min, and the ultrasonic The frequency is 60 KHz, the ultrasonic power is 900 W, the centrifugal decantation adopts a horizontal screw centrifuge, and the rotation speed of the horizontal screw centrifuge is 4500 r / min; the centrifugal separation adopts a vertical centrifuge, and the rotation speed of the vertical centrifuge is 18000 r / min min.

Embodiment 3

[0037] In this embodiment, the similarities with Embodiment 1 will not be repeated, and the difference is that, in this embodiment, the microwave power in the microwave baking pretreatment is 1200 W, and the microwave baking time is 8 min; The fresh fruit of ashwagandha was broken into pulp, the particle size of the pulp (referring to the stone fragments) was 100 mesh, the ratio of solid to liquid was 1:6, the extraction temperature was 60 °C, the time of ultrasonic-assisted extraction was 120 min, and the ultrasonic The frequency is 100 KHz, the ultrasonic power is 1500 W, the centrifugal decantation adopts a horizontal screw centrifuge, and the rotation speed of the horizontal screw centrifuge is 6000 r / min; the centrifugal separation adopts a vertical centrifuge, and the rotation speed of the vertical centrifuge is 30000 r / min min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com