Preparation method of bletilla striata polysaccharide

A technology of bletilla striata polysaccharides and bletilla striata, applied in the biological field, to achieve the effect of preventing damage, good effect, and shortening the extraction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

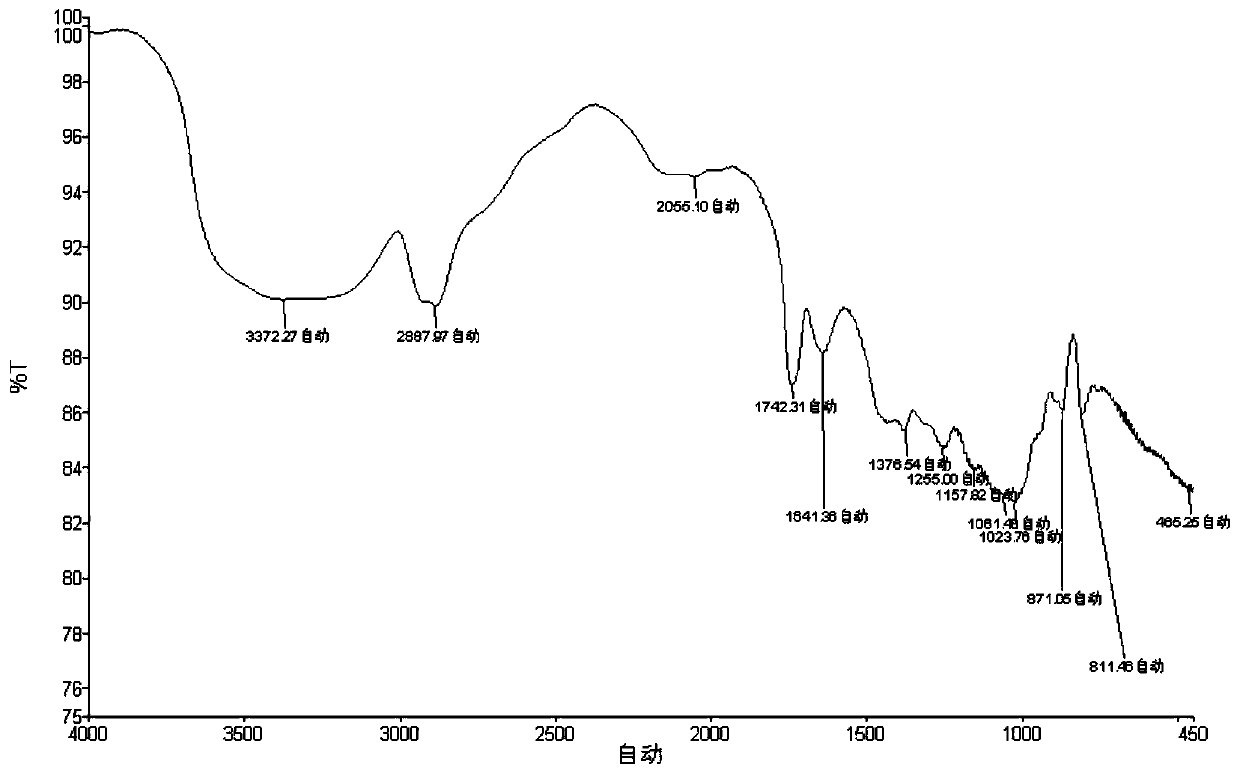

[0027] A kind of preparation method of bletilla striata polysaccharide of the present invention specifically comprises the following operation steps:

[0028] (1) Processing of raw materials of Bletilla striata: take the root of Bletilla striata and place it at a temperature of 60°C-80°C to dry to constant weight, and the dried root tuber is pulverized by a high-speed tissue grinder, and sieved to obtain Bletilla striata powder of 20 mesh to 80 mesh;

[0029] (2) Preparation of low-molecular-weight alcohol / salt two-phase system: prepare low-molecular-weight alcohol and inorganic salt two-phase system at room temperature, accurately weigh the inorganic salt, add an appropriate amount of water to prepare a certain concentration, and add an appropriate amount of Low-molecular alcohol, adjust the pH value of the solution, stir and mix thoroughly, and establish a two-phase aqueous system.

[0030] (3) Two-phase extraction combined with microwave extraction: add Bletilla striata pow...

Embodiment 1

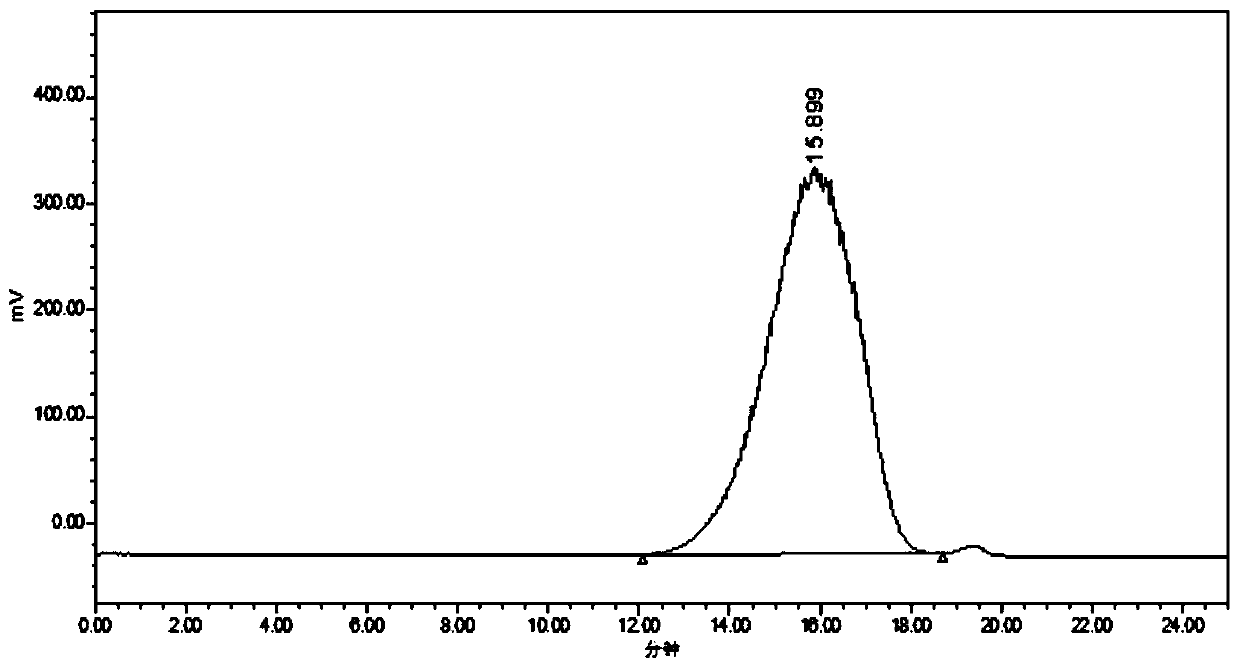

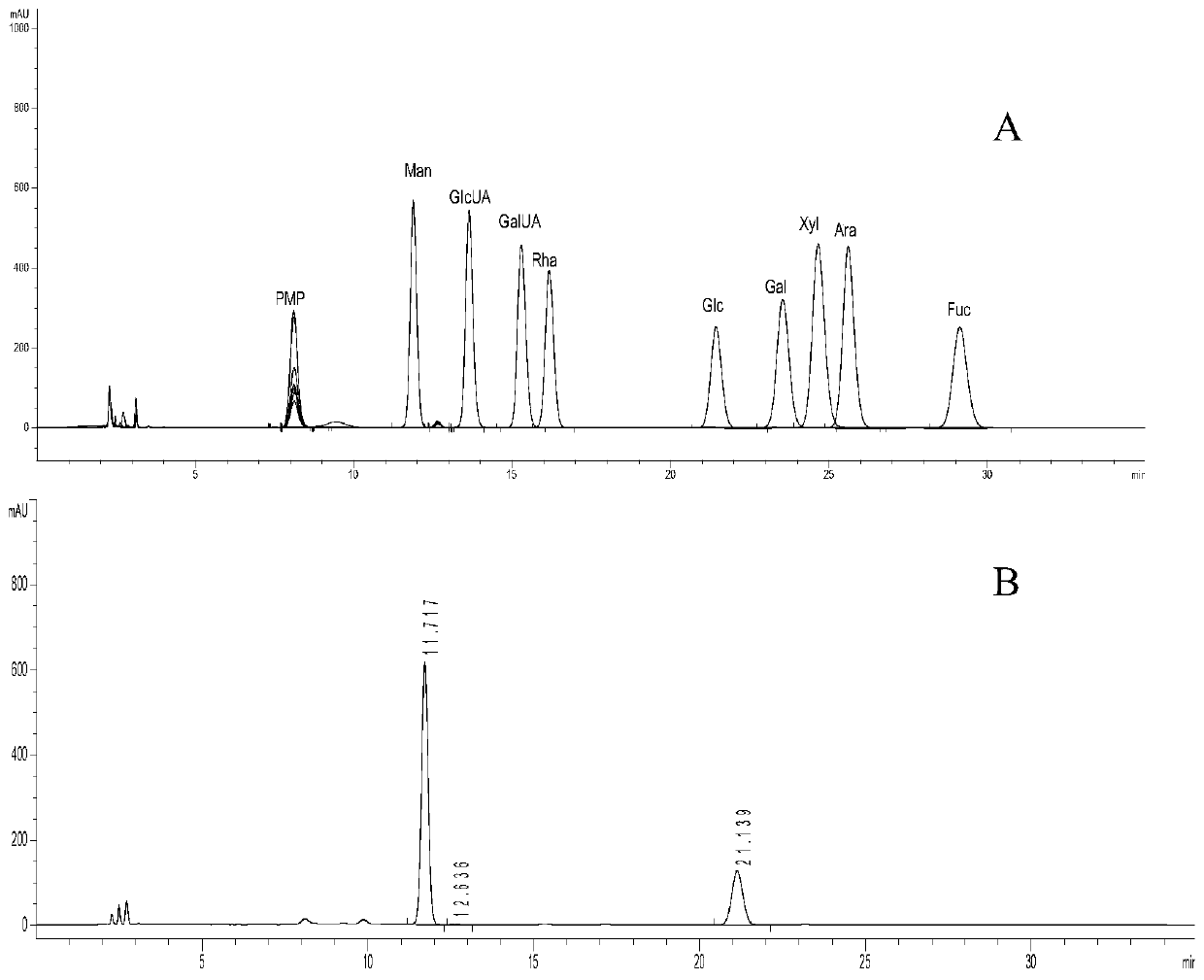

[0046] Put the tuber root of Bletilla striata at 60°C-80°C and dry it to constant weight. The dry tuber root is pulverized by a high-speed tissue grinder and sieved to obtain Bletilla striata powder of 20 mesh to 80 mesh; according to the design in Table 1, weigh a certain amount of Sodium carbonate and a certain volume of absolute ethanol, first add ultrapure water and stir to dissolve the inorganic salts, then add absolute ethanol, and finally add water to a final volume of 1000ml, stir well, and adjust the pH of the two-phase solution to 7.5. Weigh a certain amount of Bletilla striata powder, add it to the two-phase aqueous system, stir continuously, microwave at 400W, 50°C for 120 minutes to fully separate the Bletilla striata polysaccharide, let it stand for 60 minutes, and centrifuge at 10,000rpm for 30 minutes to separate the Bletilla striata polysaccharide For the extract phase, the extract phase is subjected to ultrafiltration and desalination with an ultrafiltration m...

Embodiment 2

[0050] Put the tuber root of Bletilla striata at 60°C-80°C and dry it to constant weight. The dry tuber root is pulverized by a high-speed tissue grinder and sieved to obtain Bletilla striata powder of 20 mesh to 80 mesh; according to the design in Table 1, weigh a certain amount of Disodium hydrogen phosphate and a certain volume of absolute ethanol, first add ultrapure water and stir to dissolve the inorganic salts, then add absolute ethanol, and finally add water to a final volume of 1000ml, stir well, and adjust the pH of the two-phase solution to 7.5. Weigh a certain amount of Bletilla striata powder, add it to the two-phase aqueous system, stir continuously, microwave at 400W, 50°C for 120 minutes to fully separate the Bletilla striata polysaccharide, let it stand for 60 minutes, and centrifuge at 10,000rpm for 30 minutes to separate the Bletilla striata polysaccharide For the extract phase, the extract phase is subjected to ultrafiltration and desalination with an ultraf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com