Drug excipient and preparation method thereof

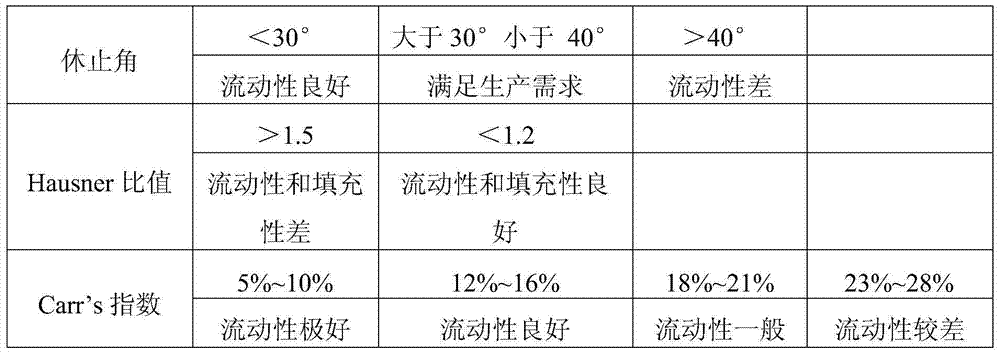

An excipient and a technology for preparing medicines, applied in the field of starch modification and application, can solve the problems of many additives and side effects, and achieve the effect of reducing application, reducing side effects and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A pharmaceutical excipient, prepared by cross-linking and cooperating enzymatic hydrolysis of starch, the preparation method is as follows:

[0042] (1) Adjust the waxy rice starch into starch milk with a mass fraction of 20% with distilled water, and add Na 2 CO 3 ;

[0043] (2) Regulate the pH of the starch milk to 11 with the NaOH solution of 1mol / L, add sodium trimetaphosphate equivalent to 3% of the waxy rice starch quality;

[0044] (3) stirring and reacting at 40° C. for 3 h, adjusting the pH to 6.5 with 1 mol / L HCl solution to complete the reaction, and obtaining the reacted starch milk;

[0045] (4) Add 95% ethanol to the reacted starch milk to carry out suction filtration, wash 5 times, then wash 2 times with NaCl solution with a mass fraction of 2.5%, then dry the washed product in a blast drying oven at 45°C , pulverized, and passed through a 100-mesh standard sieve to obtain cross-linked starch;

[0046] (5) Take the above-mentioned cross-linked starch ...

Embodiment 2

[0066] A pharmaceutical excipient, prepared by cross-linking and cooperating enzymatic hydrolysis of starch, the preparation method is as follows:

[0067] (1) With distilled water, cornstarch is adjusted into starch milk with a mass fraction of 20%, and Na 2 CO 3 ;

[0068] (2) Regulate the pH of starch milk to 10 with the NaOH solution of 0.1mol / L, add the sodium trimetaphosphate equivalent to 4% of cornstarch quality;

[0069] (3) stirring and reacting at 45° C. for 2 h, adjusting the pH to 7 with 1 mol / L HCl solution to complete the reaction, and obtaining starch milk after reaction;

[0070] (4) Add 95% ethanol to the reacted starch milk for suction filtration, wash 5 times, then wash 3 times with 2.5% NaCl solution by mass fraction, then dry the washed product in a blast drying oven at 45°C , pulverized, and passed through a 100-mesh standard sieve to obtain cross-linked starch;

[0071] (5) Take the above-mentioned cross-linked starch and use an acetic acid-sodium a...

Embodiment 3

[0079] A pharmaceutical excipient, prepared by cross-linking and cooperating enzymatic hydrolysis of starch, the preparation method is as follows:

[0080] (1) Use distilled water to adjust the pea starch into starch milk with a mass fraction of 25%, and add Na 2 CO 3 ;

[0081] (2) Regulate the pH of starch milk to 9 with the NaOH solution of 1mol / L, add sodium trimetaphosphate equivalent to 5% of pea starch quality;

[0082] (3) stirring and reacting at 50° C. for 1 h, adjusting the pH to 6 with 1 mol / L HCl solution to complete the reaction, and obtaining the reacted starch milk;

[0083] (4) Add 95% ethanol to the reacted starch milk to carry out suction filtration, wash 4 times, then wash 2 times with NaCl solution with a mass fraction of 2.5%, and then dry the washed product in a blast drying oven at 45°C , pulverized, and passed through a 100-mesh standard sieve to obtain cross-linked starch;

[0084] (5) Take the above-mentioned cross-linked starch and use an acetic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Angle of repose | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com