Micro-arc oxidation treatment device and method

A technology of micro-arc oxidation and treatment device, which is applied in anodizing, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of inconvenient movement of micro-arc oxidation device, difficult transportation of repair equipment, and high maintenance cost, and achieves micro-arc oxidation. Simple oxidation method, saving maintenance and transportation costs, and reducing the effect of working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

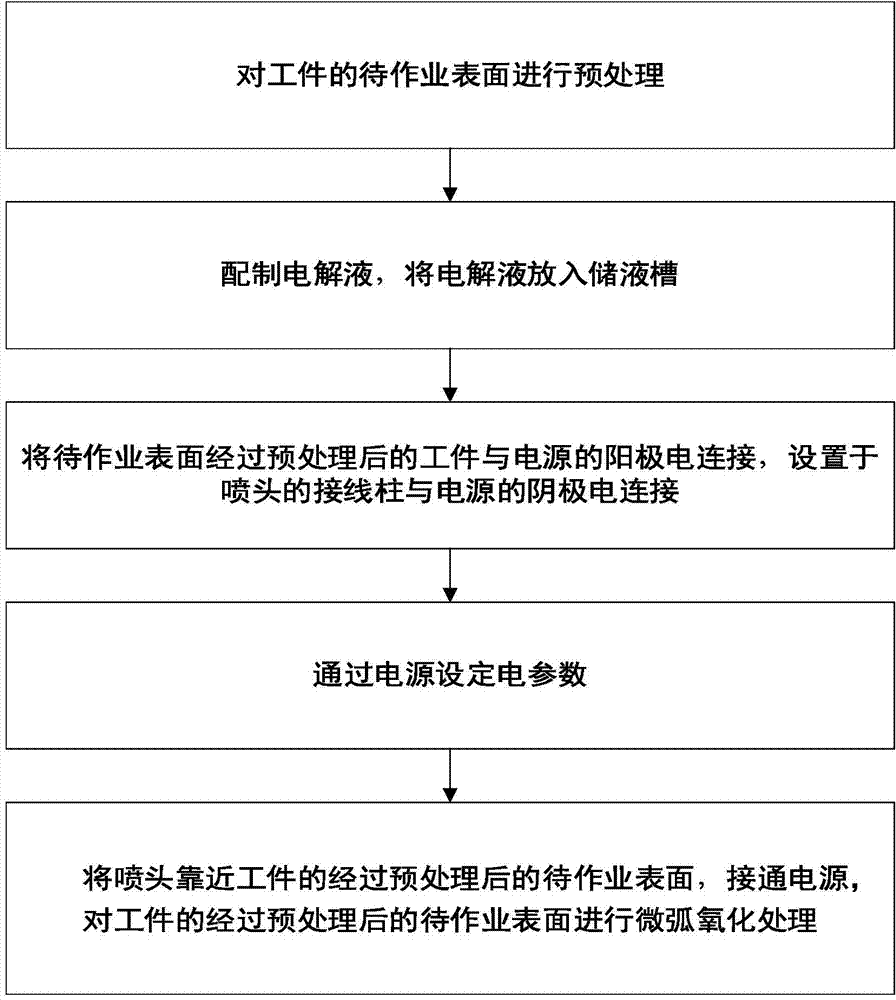

[0032] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

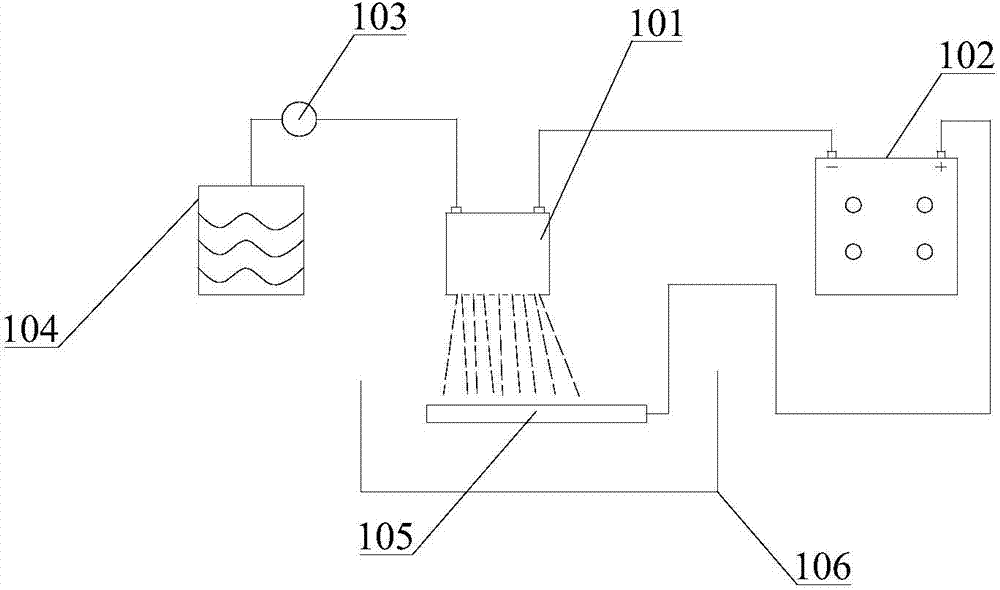

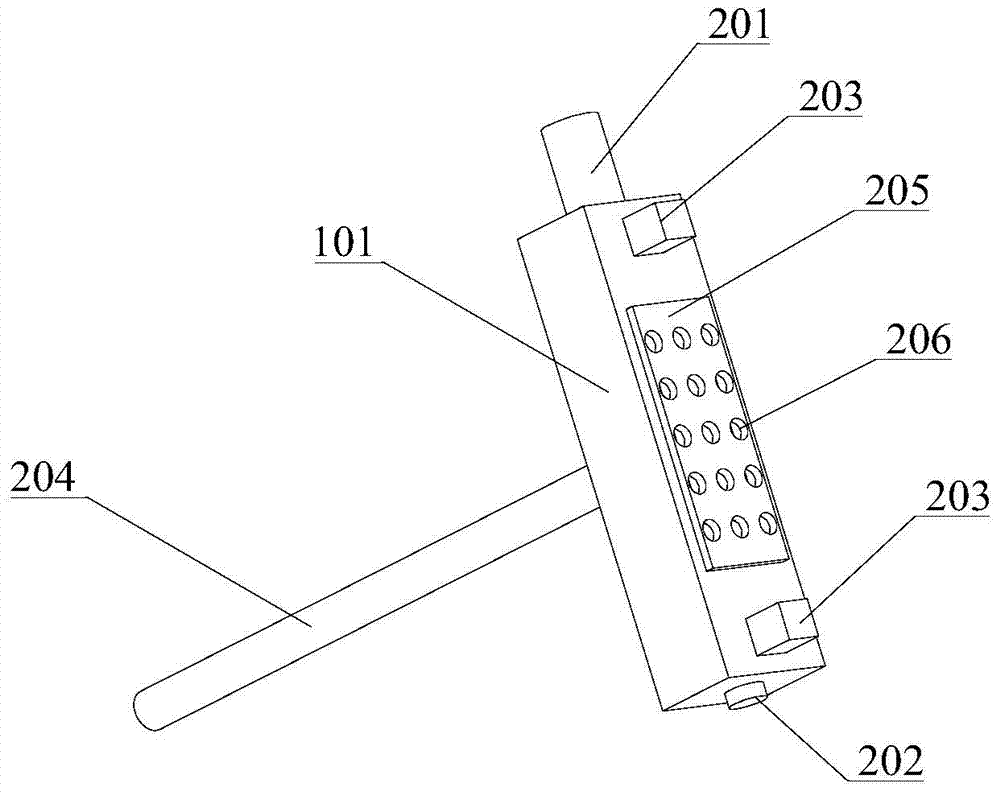

[0033] refer to Figure 1-Figure 2 , a micro-arc oxidation treatment device provided by an embodiment of the present invention, comprising: a power supply 102, a nozzle 101, a circulation pump 103, a first delivery pipe, a second delivery pipe, and a liquid storage tank 104, one end of the first delivery pipe and the nozzle 101 connection, the other end of the first delivery pipe is connected to the circulation pump 103, the circulation pump 103 is connected to the liquid storage tank 104 through the second delivery pipe, the circulation pump 103 is electrically connected to the power supply 102, and the nozzle 101 is electrically connected to the cathode of the power supply 102.

[0034] The power supply can adjust the voltage, frequency and duty cycle, where the voltage range is 0V to 700V (including 700V), the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com