Low-loss bending-resistant fiber to home

A bending-resistant, low-loss technology, used in cladding fibers, multi-layer core/cladding fibers, light guides, etc., to solve problems such as reduced efficacy, improve quality, good output beam quality, and reduce high-power amplification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

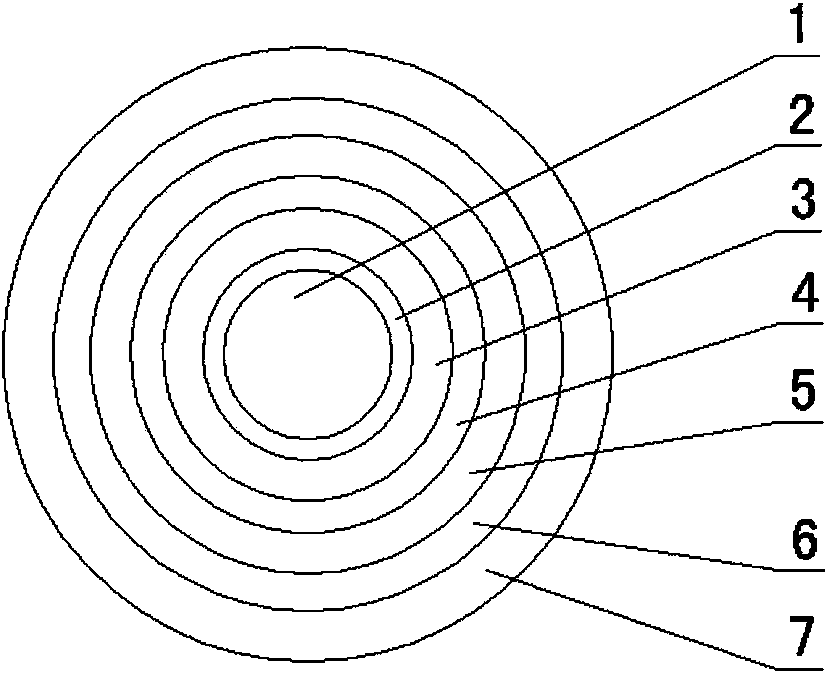

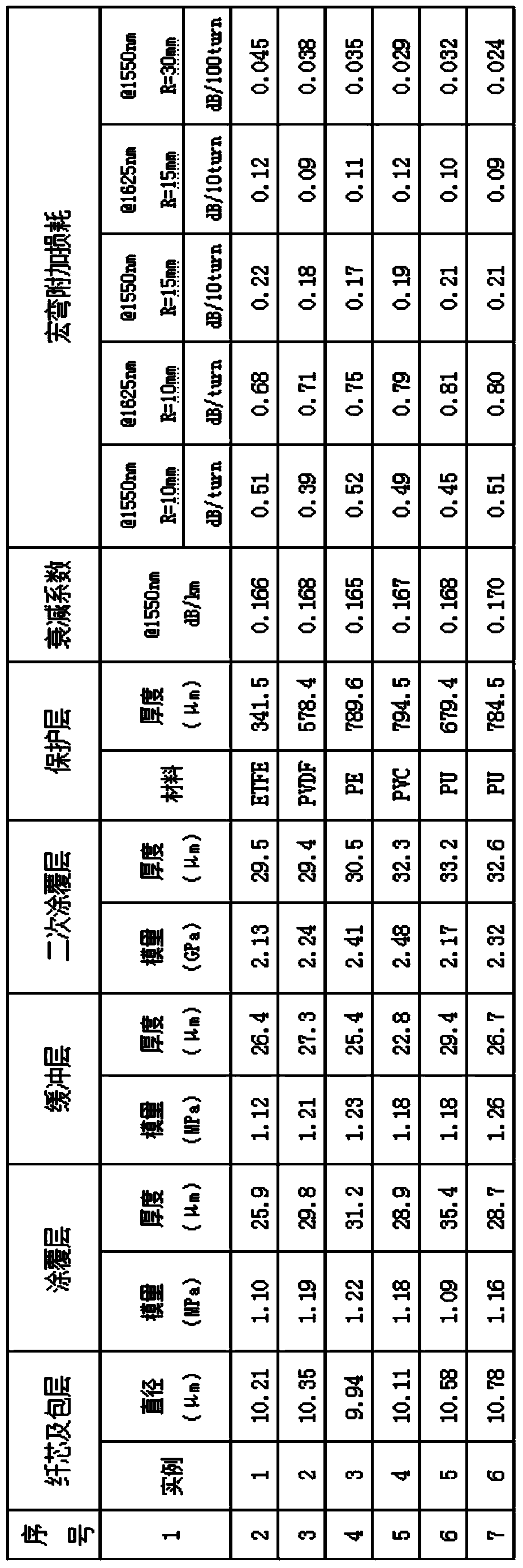

[0027] see figure 1 , the structural form of the low-loss bending-resistant home optical fiber in this embodiment is: a rare earth-doped fiber core 1 is used, and an inner cladding 2 and an outer cladding 3 are respectively formed on the surface of the rare earth-doped fiber core 1 from the inside to the outside, and the outer cladding 3 , and sequentially set the primary coating layer 4, the buffer layer 5, the secondary coating layer 6 and the outer protective layer 7 from the inside to the outside.

[0028] In specific implementation, the rare earth-doped fiber core 1 is made of silicon dioxide doped with a rare earth element compound and a co-dopant; further, the rare earth element compound doped in the rare earth-doped fiber core 1 is a halide of thulium , the doping concentration of the rare earth element compound is 5000-20000ppm; the co-dopant is germanium salt or aluminum salt, the doping concentration of the co-dopant is 12000-20000ppm, and the rare earth-doped core ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com