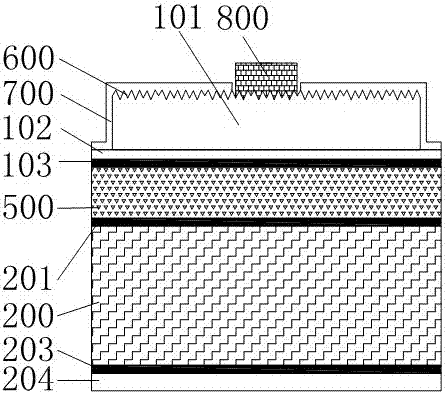

Preparation method of vertical structure LED thin film chip capable of releasing stress

A vertical structure, thin-film chip technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of chip displacement, device lithography difficulty, single chip bulging, etc., to release residual stress, improve photoelectric performance, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

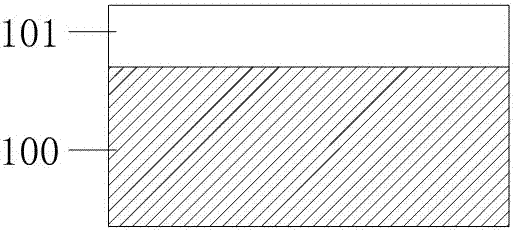

[0048] (1), such as figure 2As shown, a substrate 100 is provided on which an LED thin film 101 is grown, wherein the LED thin film 101 includes a buffer layer, an n-type layer, a light emitting layer and a p-type layer. Preferably, the material of the substrate 100 is Si, and the LED thin film 101 is an AlGaInN thin film grown by MOCVD. In other embodiments of the present invention, the substrate 100 can also be any one of sapphire, SiC, GaN, GaAs or AlN, and the LED thin film 101 is not limited to AlGaInN thin film, and can also be other Semiconductor thin films that require stress release, such as aluminum gallium indium phosphide epitaxial films on gallium arsenide substrates.

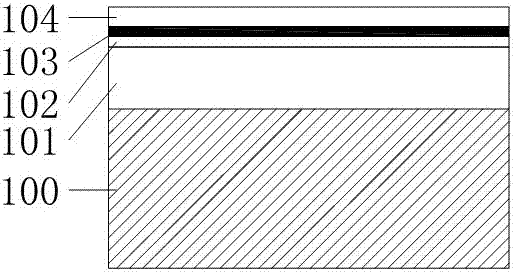

[0049] (2), such as image 3 As shown, a reflective contact layer 102 , a barrier layer 103 and a first bonding layer 104 are sequentially formed on the LED film 101 by electron beam evaporation. The reflective contact layer 102 has good ohmic contact performance with the GaN-based LED thin fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com