Composite ceramic coating, lithium ion battery composite ceramic diaphragm and lithium ion battery

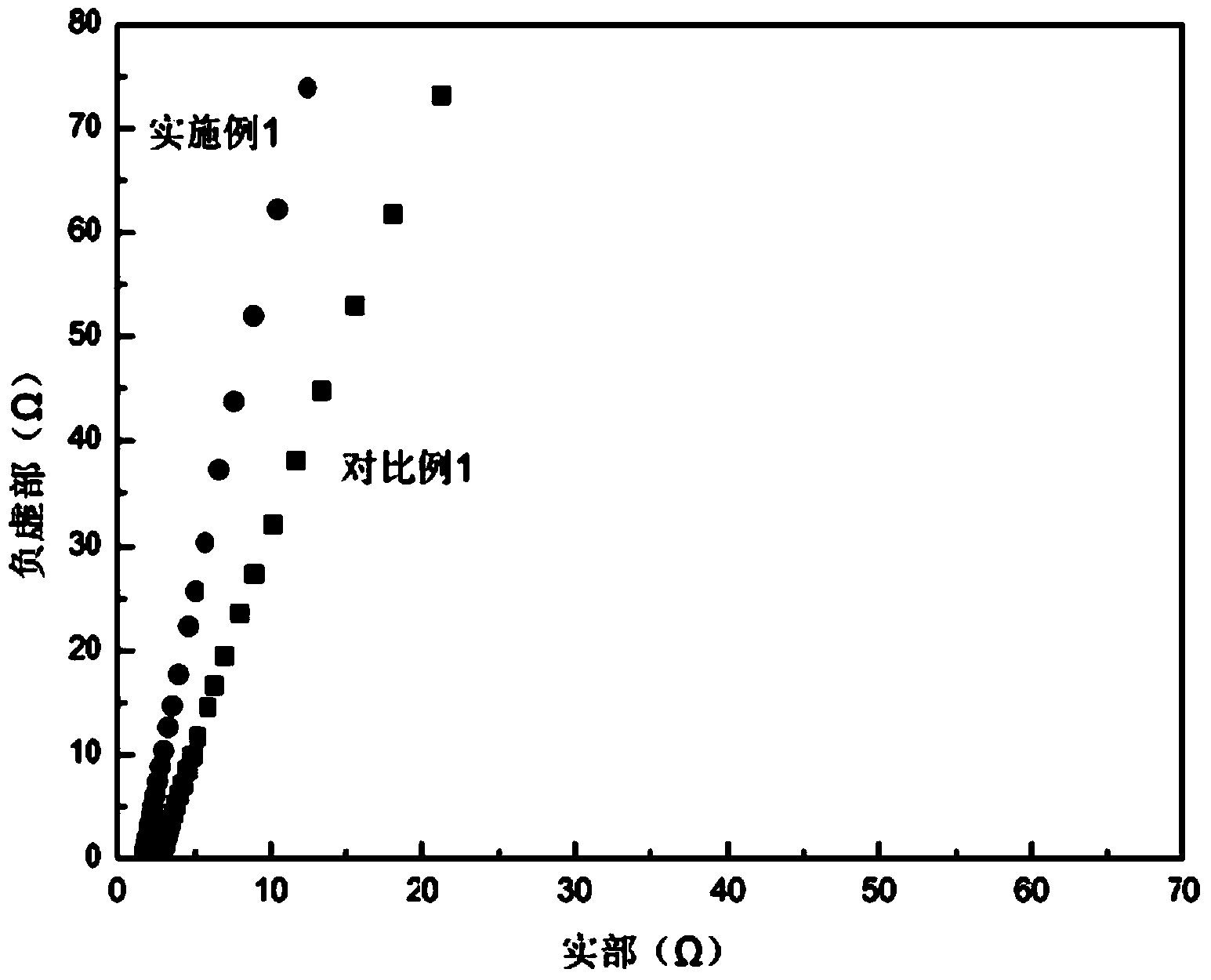

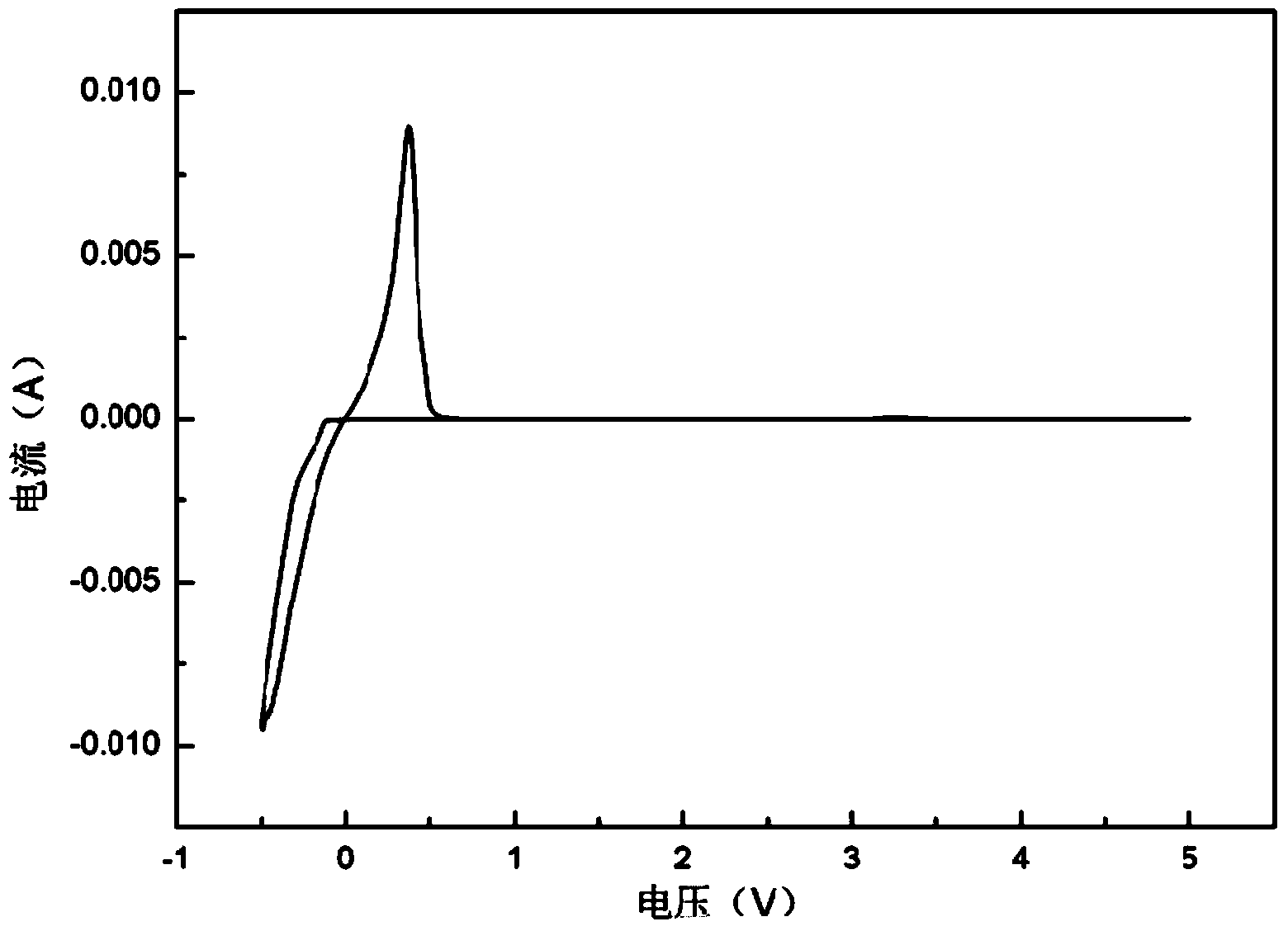

A technology of lithium-ion batteries and composite ceramics, which is applied to battery components, separators/films/diaphragms/spacers, circuits, etc., and can solve the problems of degraded battery electrochemical performance and increased internal resistance of lithium-ion batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The composite ceramic paint of the present embodiment comprises aluminum oxide powder (ceramic powder), Li 5 La 3 Ta 2 o 12 Powder (inorganic solid electrolyte powder), binder and water; the mass ratio of the ceramic powder to the inorganic solid electrolyte powder is 3:4, and the sum of the mass of the ceramic powder and the inorganic solid electrolyte powder is the water mass The mass of the binder is 2% of the sum of the mass of the ceramic powder and the inorganic solid electrolyte powder; the binder is PTFE and SBR, and the mass ratio of PTFE to SBR is 1:1.

[0047] The preparation method of the composite ceramic paint of the present embodiment is as follows:

[0048] Take 15kg of Al2O3 powder and 20kg of Li 5 La 3 Ta 2 o 12 Add the powder into the deionized water of the formulated amount, disperse with a stirrer at a speed of 300 rpm for 30 minutes, add the formulated amount of PTFE and SBR, disperse at a high speed of 1200 rpm for 120 minutes, and then per...

Embodiment 2

[0053] The composite ceramic coating of the present embodiment comprises silicon dioxide powder (ceramic powder), Li 2 O-P 2 o 5 Binary system powder (inorganic solid electrolyte powder), binder and water; the mass ratio of the ceramic powder to the inorganic solid electrolyte powder is 2:5, the sum of the mass of the ceramic powder and the inorganic solid electrolyte powder It is 50% of the mass of water, and the mass of the binder is 5% of the sum of the mass of the ceramic powder and the inorganic solid electrolyte powder; the binder is PTFE.

[0054]The preparation method of the composite ceramic paint of the present embodiment is as follows:

[0055] Take 10kg of silica powder and 25kg of Li 2 O-P 2 o 5 Add the binary system powder into deionized water with the formula amount, disperse with a stirrer at a speed of 500rpm for 60min, add the formula amount of PTFE, disperse at a speed of 1500rpm for 100min at a high speed, and perform vacuum defoaming treatment to obta...

Embodiment 3

[0060] The composite ceramic coating of the present embodiment comprises barium sulfate powder (ceramic powder), Li 2 O-P 2 o 5 -B 2 o 3 Ternary system powder (inorganic solid electrolyte powder), binder and water; the mass ratio of the ceramic powder to the inorganic solid electrolyte powder is 1:6, the sum of the mass of the ceramic powder and the inorganic solid electrolyte powder The mass of water is 29.2%, and the mass of binder is 9% of the sum of the mass of ceramic powder and inorganic solid electrolyte powder; the binder is CMC and PTFE, and the mass ratio of PTFE to CMC is 6:5.

[0061] The preparation method of the composite ceramic paint of the present embodiment is as follows:

[0062] Take 5kg of barium sulfate powder and 30kg of Li 2 O-P 2 o 5 -B 2 o 3 The ternary system powder is added to deionized water with the prescribed amount, dispersed with a stirrer at a speed of 600rpm for 50 minutes, added with the prescribed amount of PTFE and CMC, dispersed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com