Solid electrolyte and secondary battery

A solid electrolyte and secondary battery technology, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, and electrolyte batteries, and can solve the problems of high interface resistance and low battery performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

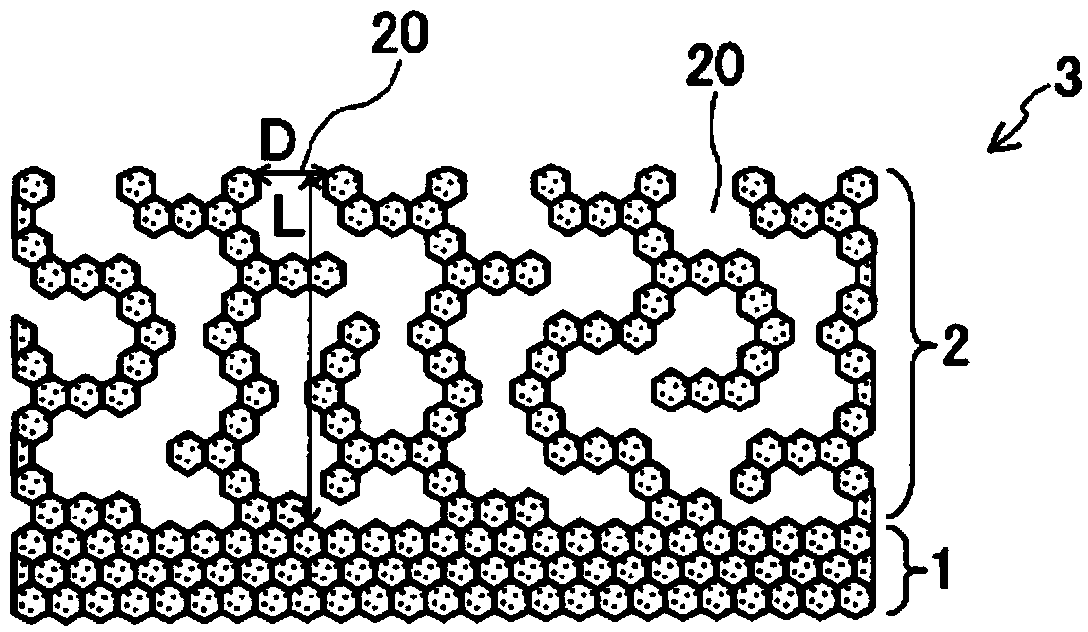

[0098] The solid electrolyte 3 of this example is as figure 1 As shown, it is composed of a dense part 1 and a porous part 2 formed on the surface side of a solid electrolyte 3 continuous with one surface of the dense part 1 . The dense part 1 has a planar shape. The sintered density of the dense part 1 was 98%. The open porosity of the dense part 1 is less than 1%. The thickness of the dense part 1 is about 50 μm. The ratio of the thickness of dense portion 1 to the entire thickness of solid electrolyte 3 was 25%.

[0099] The porosity of the porous portion 2 was 80%, and the open porosity of the porous portion 2 was 75%. The ratio of the open porosity of the porous portion 2 to the porosity of the porous portion 2 was 94%. The average opening diameter D of the open pores 20 opened on the surface of the porous portion 1 was 50 μm. The average depth L of the open pores 20 was 48 μm. The thickness of the porous portion 2 is about 100 μm. The ratio of the thickness of th...

Embodiment 2

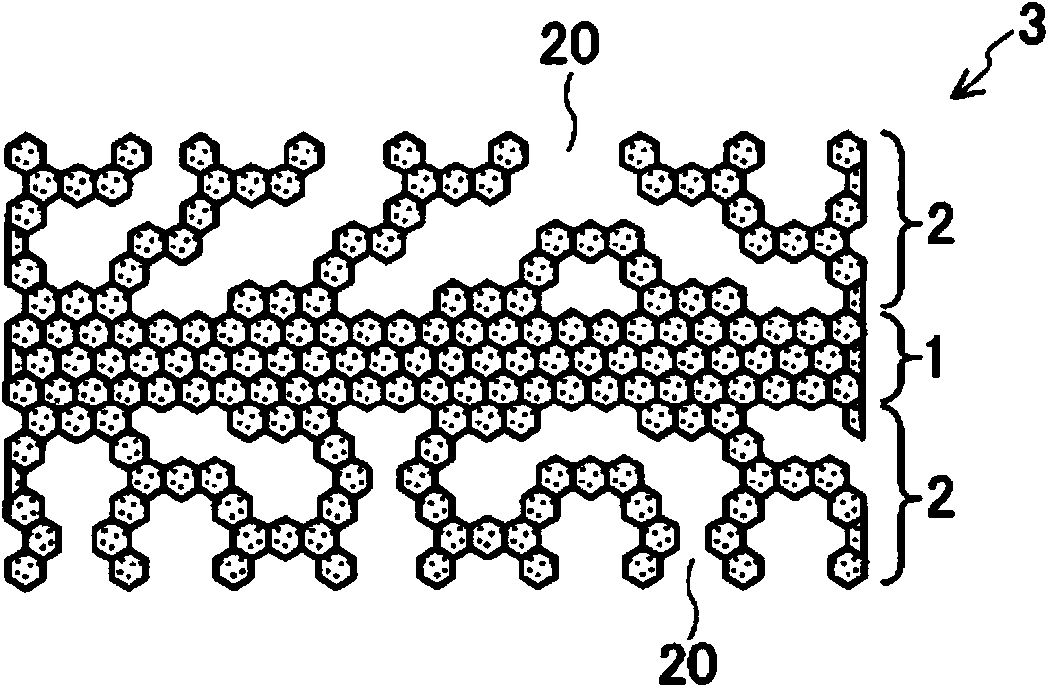

[0104] The solid electrolyte 3 of this example is as figure 2 As shown, the porous portion 2 is formed on both the front and back surfaces of the dense portion 1 . The thickness of the dense part 1 was 50 μm, and the thickness of each porous part 2 was 100 μm. The ratio of the thickness of dense portion 1 to the thickness of the solid electrolyte 3 as a whole was 20%. After the dense part 1 is formed, the solid electrolyte slurry is applied to both the front and back sides of the dense part 1, freeze-dried, and fired. Others are the same as in Example 1.

Embodiment 3

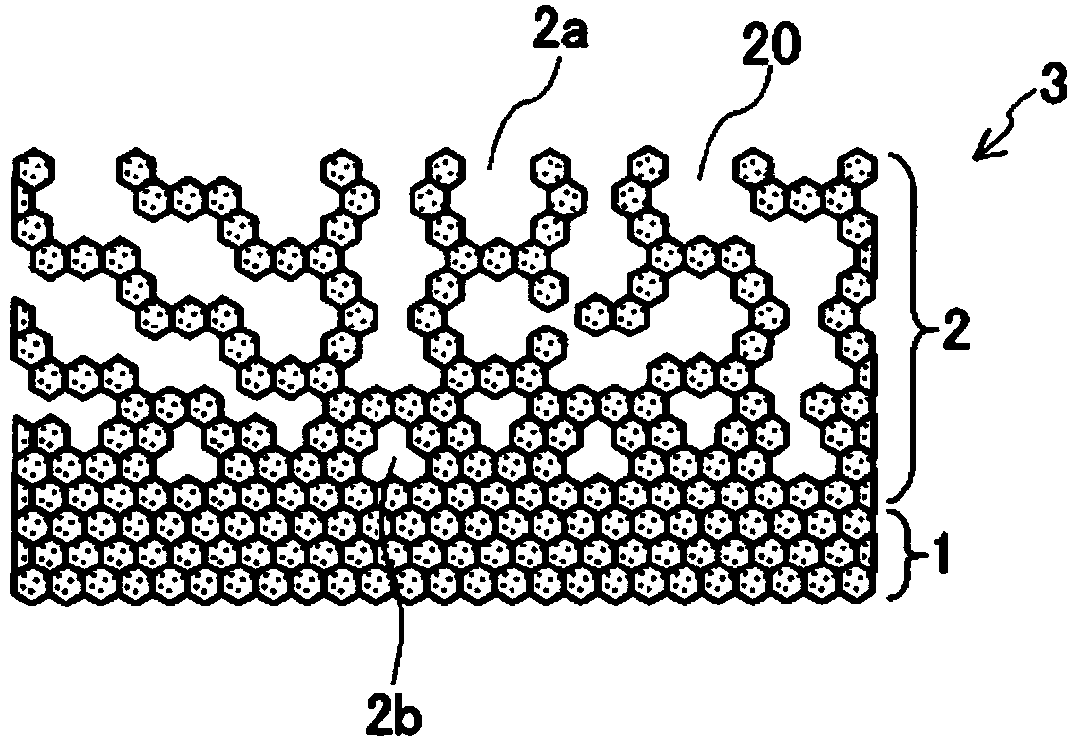

[0106] The solid electrolyte 3 of this example is as image 3 As shown, the porosity of the porous portion 2 has a gradient in the thickness direction. The porosity of the porous part 2 is 80% in the surface layer part 2a, and gradually decreases toward the inside, and the porosity is almost 0% in the inner part 2b near the dense part 1 in the porous part 2. When forming the porous part 2, with figure 1 Similarly, the solid electrolyte slurry was applied to the surface of the dense part 1, freeze-dried, and fired. The conditions for freeze-drying are to install a cooling medium on the top of the molded body and cool the molded body while imparting a temperature gradient. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com