Reverse osmosis membrane treatment process for recycling industrial sewage and realizing zero release

A technology of industrial sewage and treatment process, which is applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. higher question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

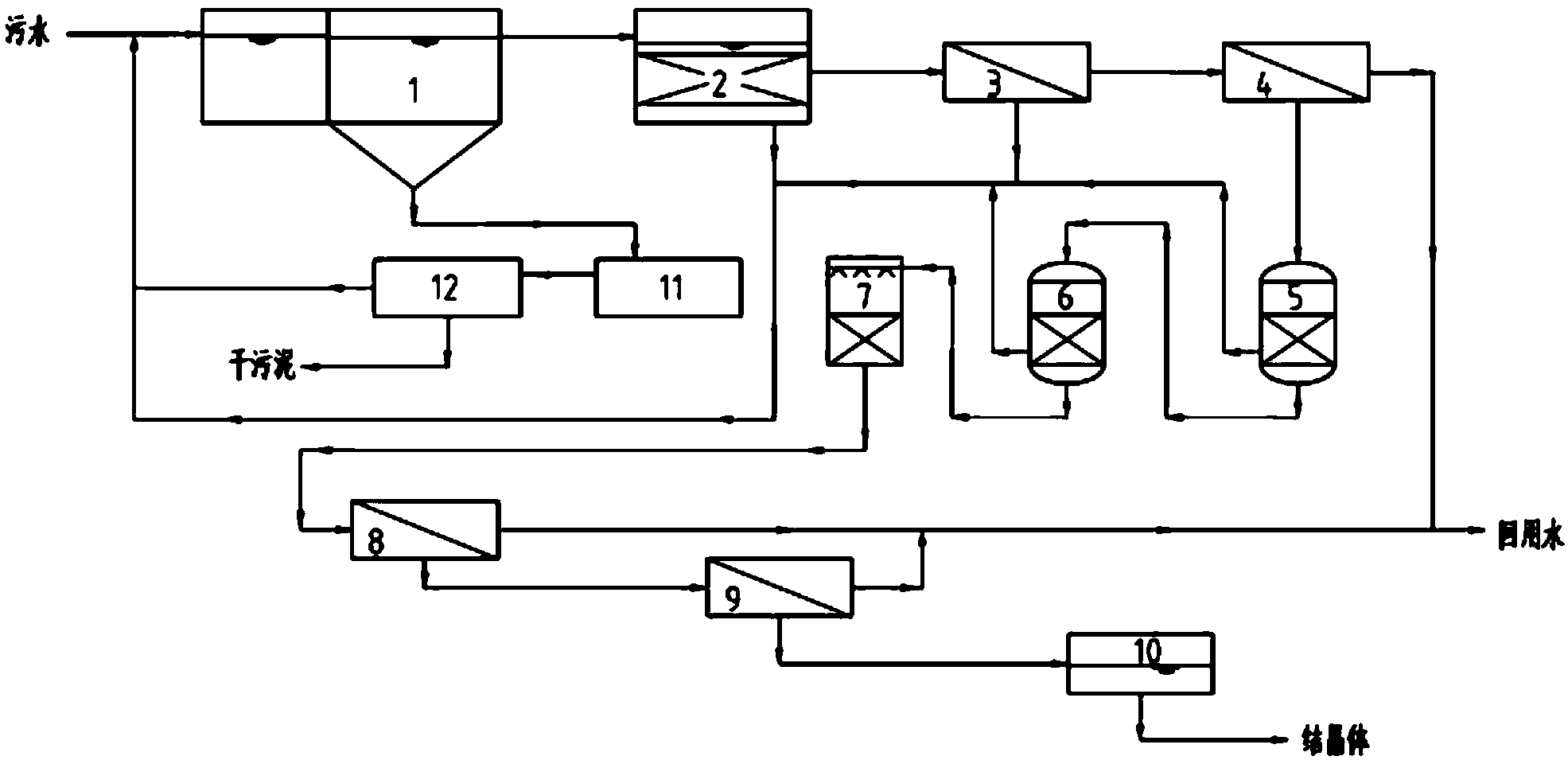

[0031] see figure 1 , The invention discloses a reverse osmosis membrane treatment process for industrial sewage reuse and zero discharge. As shown in the figure: it is softened by lime to remove alkali clarification tank 1, filter tank 2, ultrafiltration device 3, primary reverse osmosis device 4, weak acid type cation exchanger 5, strong acid type cation exchanger 6, carbon remover 7 , Concentrated water reverse osmosis device 8, concentrated reverse osmosis device 9, evaporation crystallizer 10, sludge collection device 11 and sludge dehydration device 12 for treatment. The specific process is: the sewage first enters the lime softening and alkali removal clarification tank 1 , the effluent from the lime softening and alkali removal clarification tank 1 enters the filter tank 2 , and the excess sludge enters the sludge collection device 10 . The effluent from the filter 2 enters the ultrafiltration device 3, and the regularly backwashed wastewater from the filter 2 is disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com