Three-dimensional stress testing device for single-hole multi-point fiber grating hollow inclusions in rock mass engineering

A technology of hollow inclusions and fiber gratings, which is applied in the measurement of the change force of the optical properties of the material when it is stressed, can solve the problem of poor stability and anti-interference ability, low sensitivity of rock mass strain response, and unsuitable for long-term Monitoring and other issues to achieve enhanced sensitivity and precision, high reliability, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is a further detailed description of the single-hole multi-point fiber grating hollow inclusion three-dimensional stress testing device for rock mass engineering of the present invention in conjunction with the accompanying drawings.

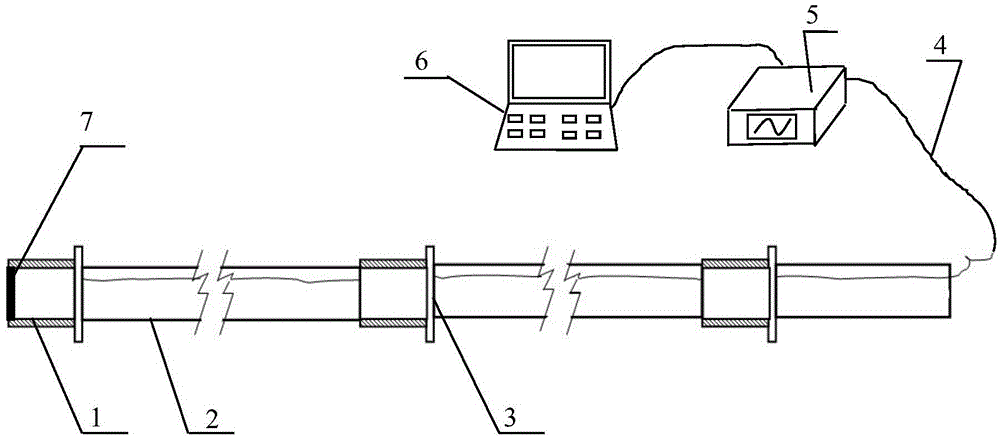

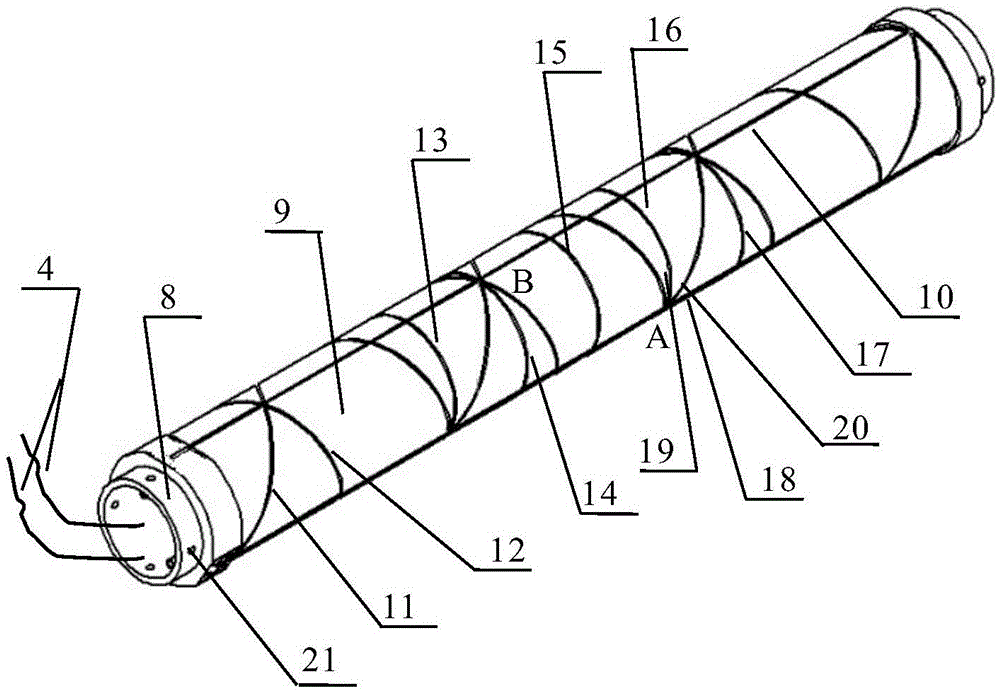

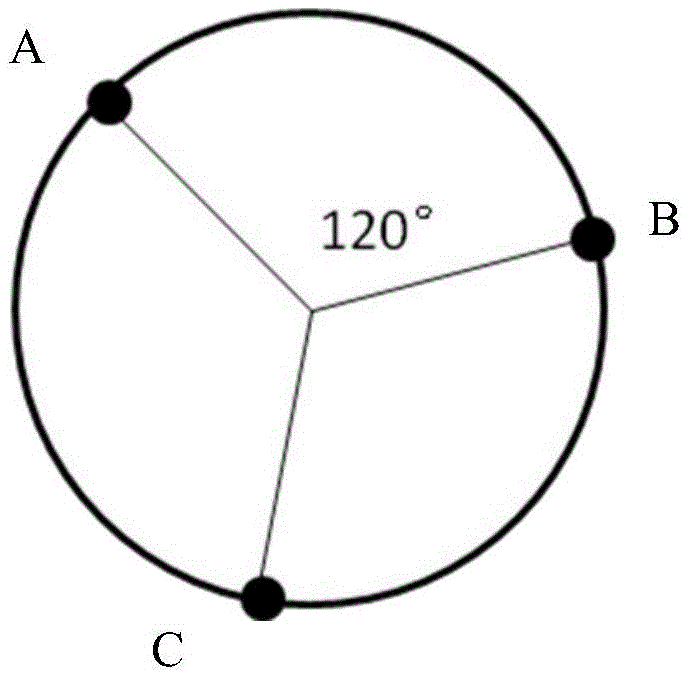

[0022] See attached figure 1 , 2 , 3, single-hole multi-point fiber grating hollow inclusion stress test device for rock mass engineering, the device is composed of more than two unit fiber grating cylindrical hollow inclusion stress gauge 1, rigid connecting rod 2, centering bracket 3, wavelength solution It consists of a regulator 5 and a computer 6. The unit optical fiber grating cylindrical hollow inclusion stress gauge 1 is composed of an epoxy resin hollow inclusion 9, a rigid connection end ring 8, and an optical fiber 4. The rigid connection end ring 8 is installed on the epoxy resin hollow inclusion At both ends of 9, the unit fiber grating cylindrical hollow inclusion stress gauge 1 is connected in series by rigid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com