Displacement representation method for preparing nanochannel fracture appearance sample

A characterization and morphology technology, which is applied in the field of cross-sectional morphology characterization of nano-channels after hot-pressing bonding based on surface modification technology, can solve the problems of difficulty in the observation and positioning of nano-channel electron microscopy, difficulty in preparation of nano-channel cross-sections, etc. The effect of clear cross-section morphology, shortened observation time, and reduced preparation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the patent of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings.

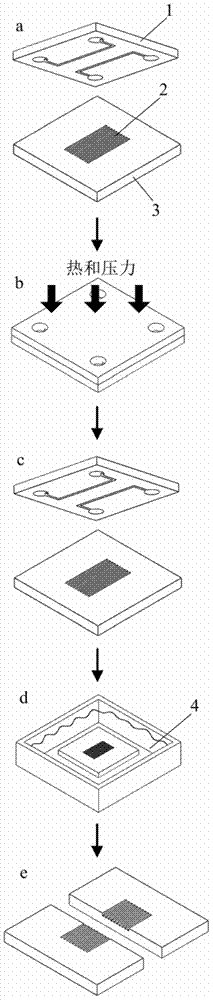

[0027] figure 1 It is a schematic diagram of the cross-sectional morphology sample of the nanochannel prepared by the displacement characterization method after thermocompression bonding.

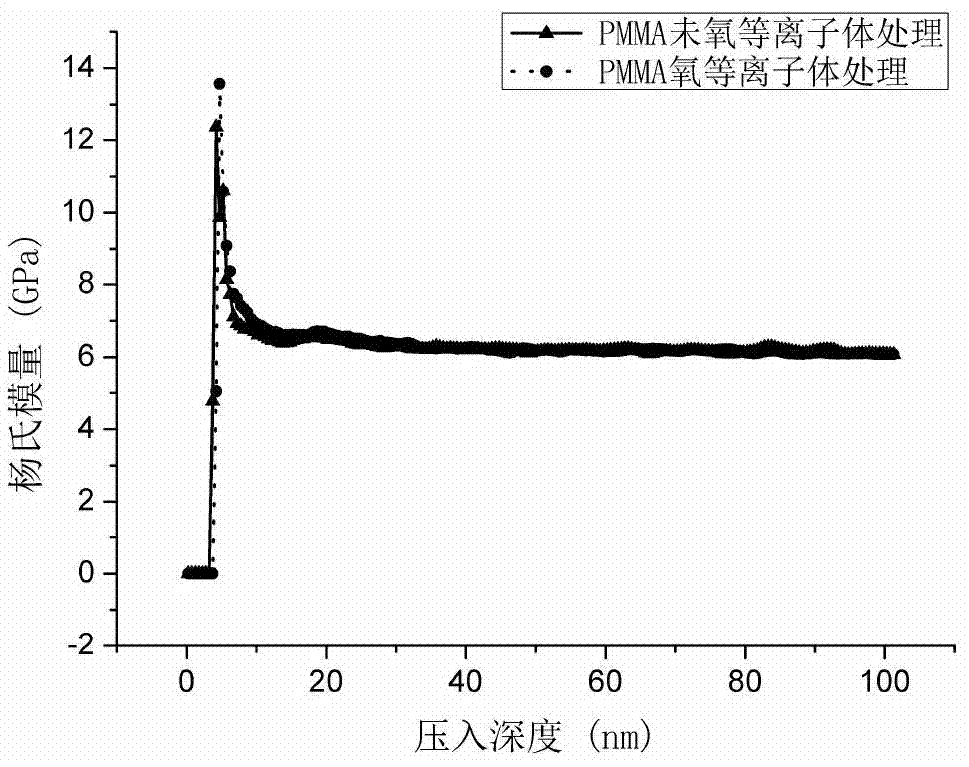

[0028] Young's modulus and hardness of PMMA surface layer material under the condition of bonding temperature in table 1

[0029]

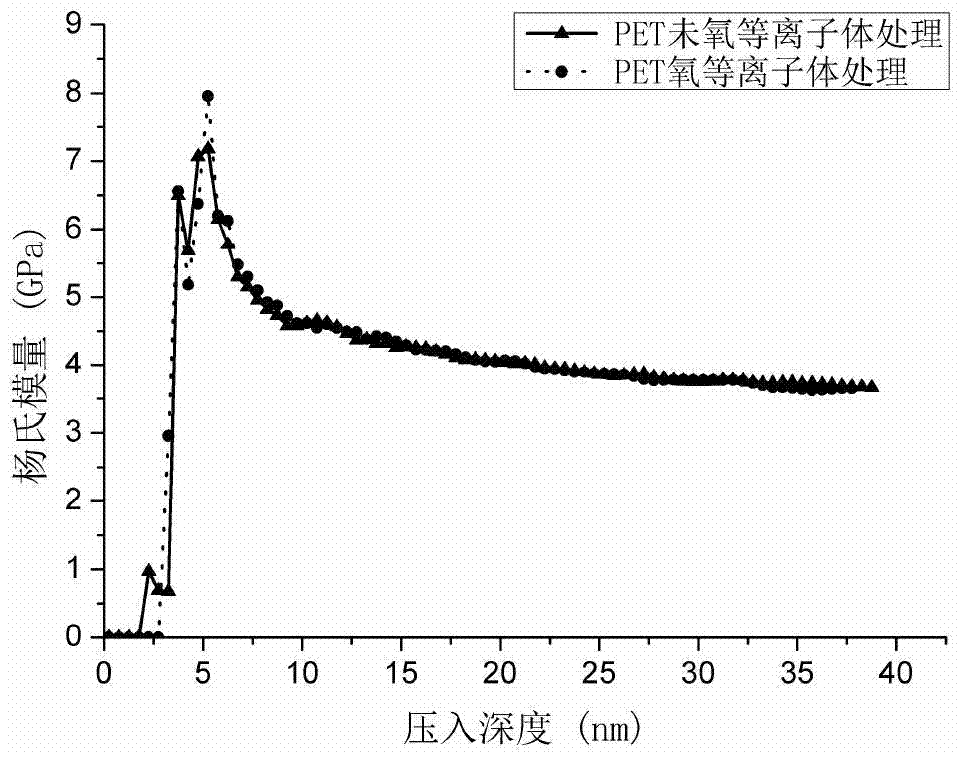

[0030] Table 2 Young's modulus and hardness of PET surface material under bonding temperature conditions

[0031]

[0032] 1. The effect of oxygen plasma treatment on the thermocompression bonding strength was analyzed by tensile strength measurement. The effect of oxygen plasma treatment on the Young's modulus and hardness of the polymer surface material (thickness 0-100nm) was quantitatively analyzed by using the surface material analysis experiment, and it was proved t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com