Molten carbonate fuel cell structure

A molten carbonate and fuel cell technology, applied in the direction of molten electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve the problems of large electrode polarization, unfavorable transmission, low battery performance, etc., and achieve improved immersion and gas barrier capabilities , reduce pollution and improve battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

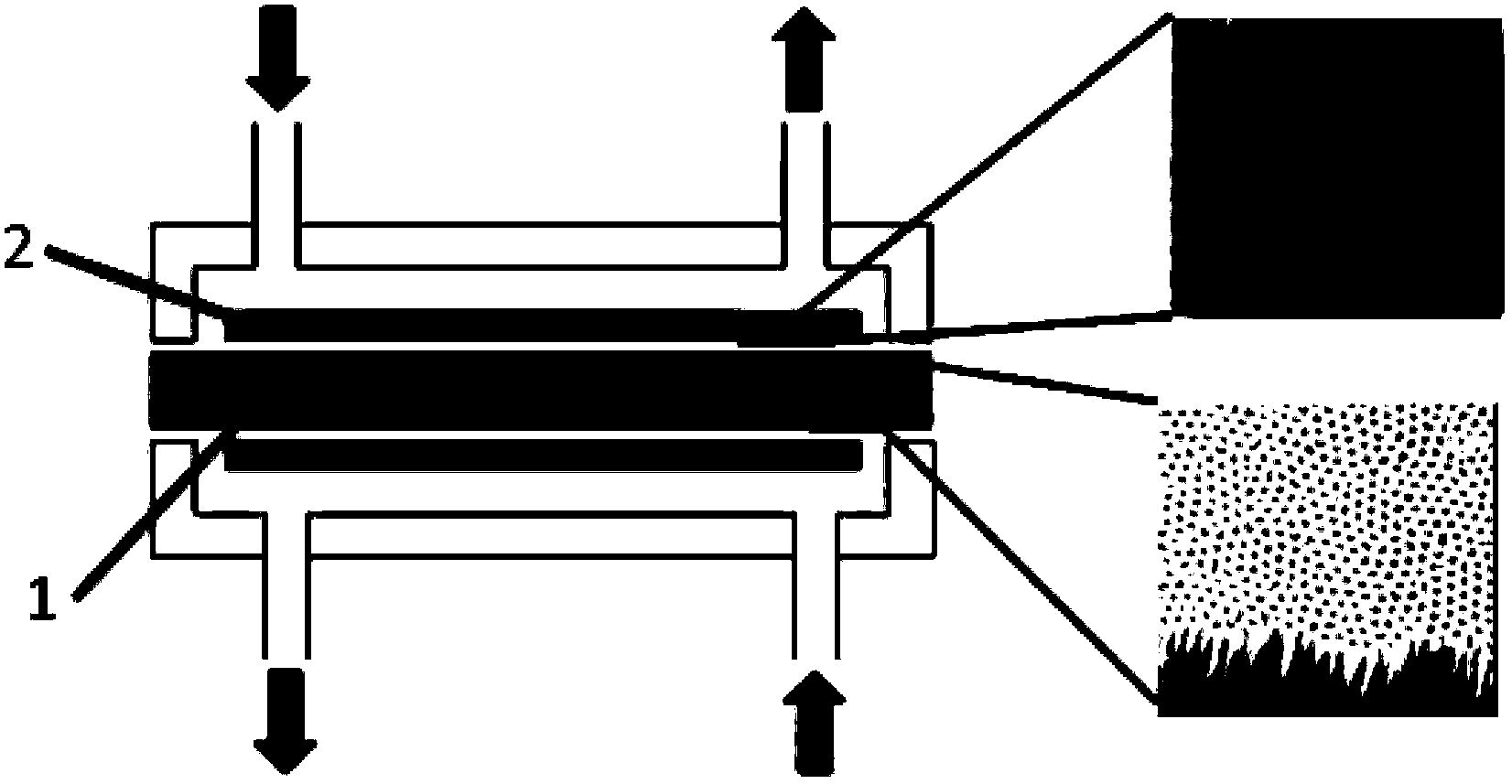

[0022] Embodiment 1: as figure 1 As shown, the present invention includes an ordered diaphragm 1 and an ordered electrode 2 . Ordered diaphragm 1 has a straight through-hole channel structure with a pore diameter of 50-200nm and a thickness of 200-400um, and is made of ceramic material α-LiAlO 2 .

[0023] The preparation process of the ordered separator 1 is as follows: AAO with a pore size of 50nm and a thickness of 300um is used as the substrate, dipped and pulled several times in a saturated potassium carbonate solution, and then placed in an oven at 80°C for 8h. After drying, place it on a smooth ceramic plate covered with a layer of quartz sand, and place it in a muffle furnace for firing. The firing procedure is as follows:

[0024] Heating from room temperature for 10 hours to 450°C, holding at 450°C for 10 hours, heating for 6 hours to 700°C, holding at 700°C for 12 hours, then cooling down to room temperature

[0025] The surface channel scanning electron microsco...

Embodiment 2

[0027] Embodiment 2: The material of the ordered diaphragm 1 included in the present invention can also be γ-LiAlO 2 , and its preparation process is as follows:

[0028] AAO with a pore size of 100nm and a thickness of 300um was used as the substrate, dipped and pulled several times in a saturated potassium carbonate solution, and then placed in an oven at 80°C for 8h. After drying, place it on a smooth ceramic plate covered with a layer of quartz sand, and place it in a muffle furnace for firing. The firing procedure is as follows:

[0029] γ-LiAlO 2 : Heating from room temperature for 10 hours to 450°C, holding at 450°C for 10 hours, heating for 6 hours to 700°C, holding at 700°C for 12 hours, heating for 5 hours to 900°C, holding at 900°C for 4 hours, then cooling down to room temperature.

[0030] The prepared ordered diaphragm and ordered electrode assembled battery were evaluated for battery, using 62mol%Li 2 CO 3 +38mol%K 2 CO 3 As the electrolyte, the anode gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com