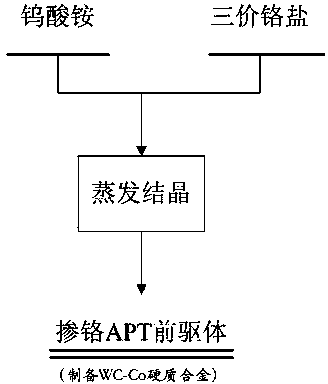

Method for preparing uniformly chromium-doped APT (ammonium paratungstate)

A technology of chromium ammonium paratungstate and ammonium tungstate, which is applied in the field of preparing uniform chromium-doped APT (ammonium paratungstate), which can solve the problems of abnormal growth and uneven distribution of inhibitors, so as to reduce costs and suppress abnormal growth of WC grains , reduce the effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing uniform chromium-doped ammonium paratungstate, the steps are as follows:

[0028] (1) Pre-dissolve WO with ammonia water 3 Preparation of ammonium tungstate solution in which WO 3 =276 g / L, NH 4 OH=4.3 mol / L, add corresponding WO 3 React with ammonia water in a reactor at 100 °C for 1 h;

[0029] (2) will be 2 m 3 Add the ammonium tungstate solution into the titanium-lined crystallization pot with a stirring speed of 70 r / min, slowly add 15.4 Kg of chromium acetate while stirring, open the steam valve and adjust the steam to 0.10-0.30MPa; the temperature is controlled at 90-100 °C, heating evaporation crystallization;

[0030] (3) After the liquid level in the crystallization pot boils completely, keep stirring and turn off the steam;

[0031] (4) When crystal nuclei appear in the crystallization pot, adjust the speed to 30 r / min and keep the steam pressure at 0.05-0.10 MPa;

[0032] (5) When the solution density reaches 1.1 g / cm 3 , cont...

example 1

[0034] Example 1 The physical properties of the chromium-doped APT powder are shown in Table 1.

[0035]

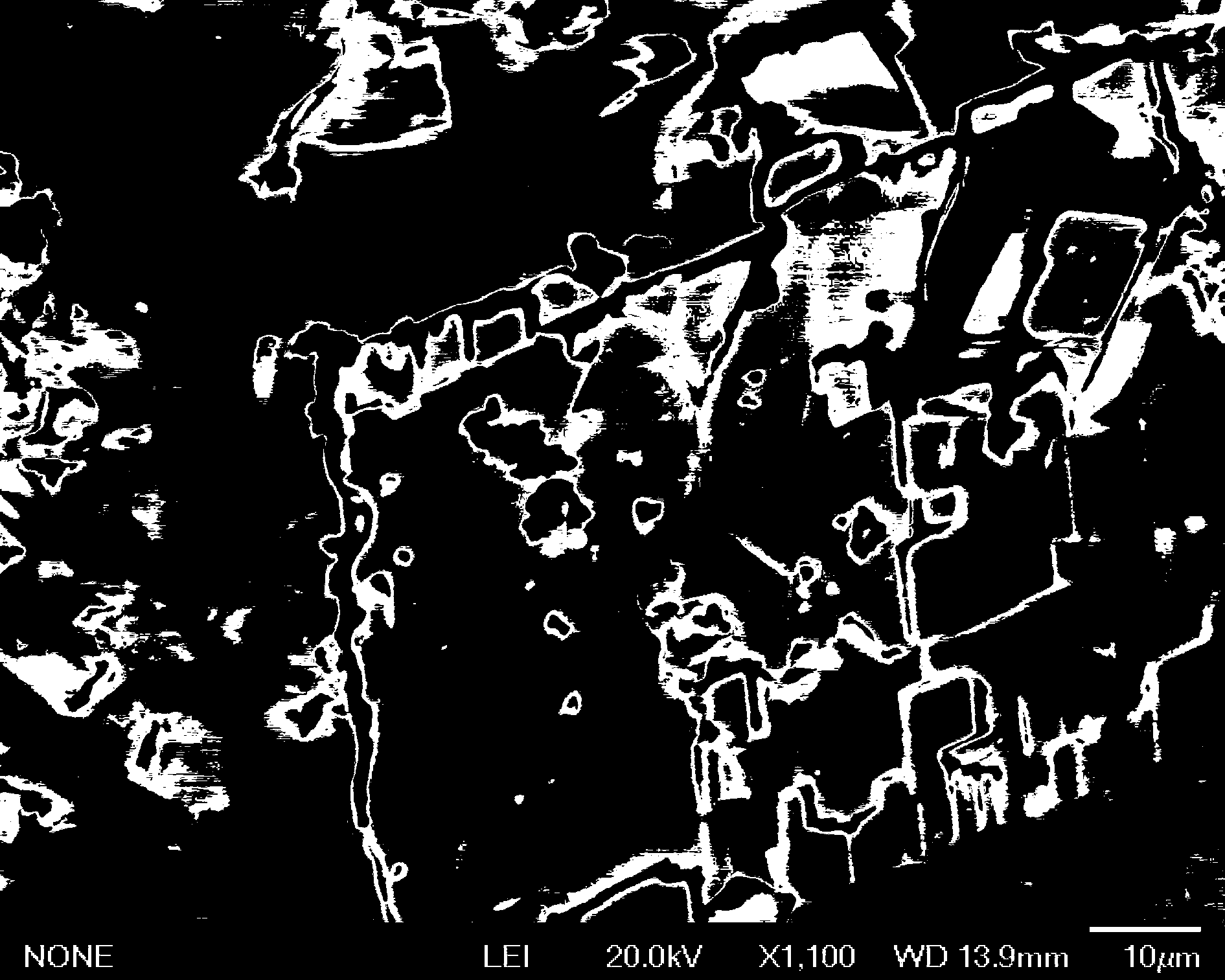

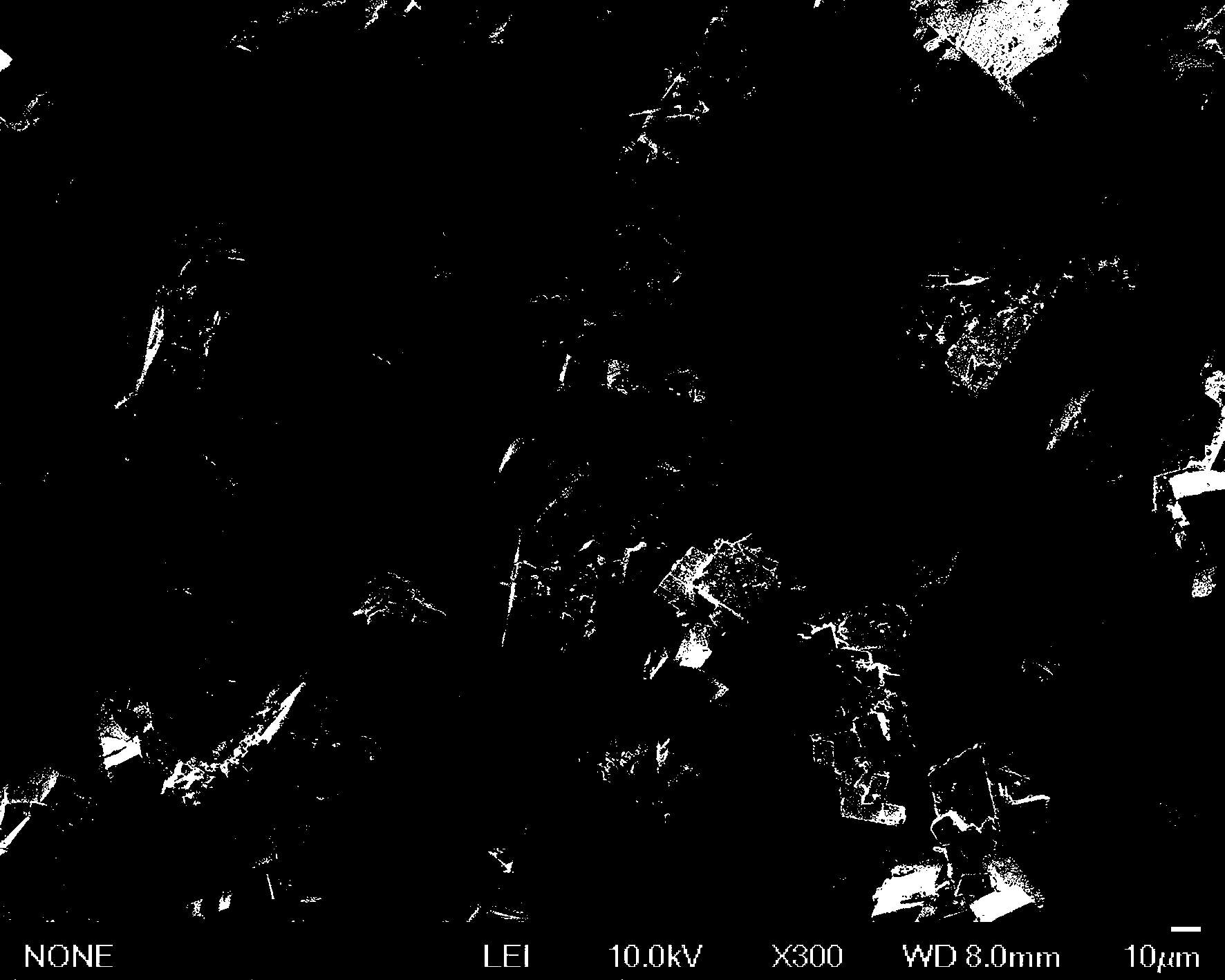

[0036] See the SEM and EDS results of this example figure 2 , image 3 , Figure 4 , XRD results see Figure 5 .

[0037] Chromium-doped APT powder is processed into WC-Co cemented carbide through calcination, hydrogen reduction, carbonization, molding, liquid phase sintering and other processes. The metallographic results are shown in Figure 6 .

Embodiment 2

[0039] A method for preparing uniform chromium-doped ammonium paratungstate, the steps are as follows:

[0040] (1) Pre-dissolve WO with ammonia water 3 Preparation of ammonium tungstate solution in which WO 3 =150 g / L, NH 4 OH=1.8 mol / L, add the corresponding WO 3 React with ammonia water in a reactor at 100 °C for 1 h;

[0041] (2) will be 3 m 3 Add the ammonium tungstate solution into the titanium-lined crystallization pot with a stirring speed of 70 r / min, slowly add 18.3 Kg of chromium acetate while stirring, open the steam valve and adjust the steam to 0.10-0.30MPa; the temperature is controlled at 90-100 °C, heating evaporation crystallization;

[0042] (3) After the liquid level in the crystallization pot boils completely, keep stirring and turn off the steam;

[0043] (4) When crystal nuclei appear in the crystallization pot, adjust the speed to 30 r / min and keep the steam pressure at 0.05-0.10 MPa;

[0044] (5) When the solution density reaches 1.1 g / cm 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com