Method for monitoring insulation state of epoxy resin insulating media in sulfur hexafluoride electrical device

An electrical equipment, sulfur hexafluoride technology, applied in the direction of measuring devices, testing dielectric strength, instruments, etc., can solve the problems of insulation breakdown, power system operation accidents, low sensitivity of epoxy resin insulation defects, etc., to achieve stable detection, Accurate detection results and sensitive identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

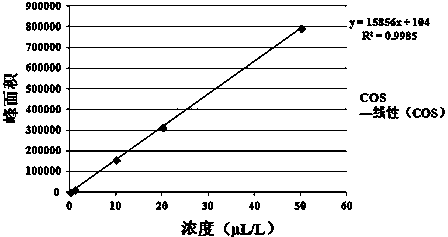

[0029] Embodiment one: gas chromatography GC

[0030] (1) Use a gas distributor to dilute the COS standard gas, establish a standard curve with a concentration gradient of 0.114, 0.550, 1.500, 4.00, 8.00, 10.00, 20.00, and 50.00 μL / L, and pass the diluted gas into the gas chromatograph in the detection. Repeat the measurement 3 times.

[0031] Determination conditions: Taking the gas chromatography with gaspro capillary column and matching PDD detector as an example, TECPφ3×3m PORAPAK Q 0.53mm×30m PORAPAK Qφ3×3m capillary column is used. The specific parameters are set as follows:

[0032] Gas connection:

[0033] A. Carrier gas: helium (above 99.999%), output pressure 0.4MPa

[0034] B. Driving gas: Nitrogen, the output pressure of driving gas is 0.3MPa

[0035] Injection pressure: 0.05MPa

[0036] The column furnace was initially at 35°C, kept for 8 minutes, then raised to 200°C at a rate of 10°C per minute, and kept for 5 minutes.

[0037] Based on the above ...

Embodiment 2

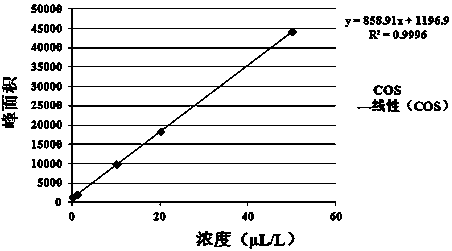

[0045] Embodiment 2: Gas chromatography-mass spectrometry GC-MS

[0046] (1) Use a gas distributor to dilute the COS standard gas, establish a standard curve with a concentration gradient of 0.114, 0.550, 1.500, 4.00, 8.00, 10.00, 20.00, and 50.00 μL / L, and pass the diluted gas into the analytical instrument for analysis. detection. Repeat the measurement 3 times.

[0047] Determination conditions:

[0048] A gas pro capillary column, model J&W, 30 m×0.32 mm×0.35 μm was selected. The chromatographic column has a good separation effect and can achieve the same decomposition product as the background SF 6 Maximum separation. The specific parameters are as follows:

[0049]

[0050] Based on the above parameter settings, COS can be characterized as:

[0051]

[0052] get figure 2 The standard curve for COS is shown:

[0053]

[0054] (2) Gathering gas samples: According to DL / T 1032-2006 "Sampling Method of Sulfur Hexafluoride Gas for Electrical Equipment", SF6...

Embodiment 3

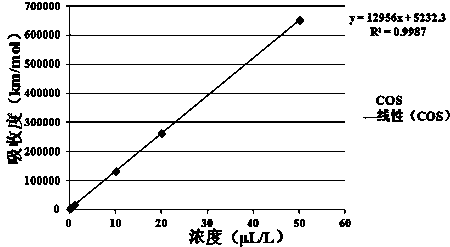

[0059] Embodiment three: Fourier transform infrared spectroscopy FTIR

[0060] (1) Use a gas distributor to dilute the COS standard gas, establish a standard curve with a concentration gradient of 0.114, 0.550, 1.500, 4.00, 8.00, 10.00, 20.00, and 50.00 μL / L, and pass the diluted gas into the analytical instrument for analysis. detection. Repeat the measurement 3 times. The specific parameters of the Fourier transform infrared spectrometer used are as follows:

[0061]

[0062] Based on the above settings, COS can be characterized as:

[0063]

[0064] get image 3 The standard curve for COS is shown:

[0065]

[0066] (2) Collect gas samples: According to the method specified in DL / T 1032-2006 "Sulfur Hexafluoride Gas Sampling Method for Electrical Equipment", SF6 gas from a GIS gas chamber of Guangdong Power Grid Company was collected as the sample to be tested.

[0067] (3) Detection: The sample to be tested is passed into a Fourier transform infrared spectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com