Transient test control method and system used in debugging and starting process of nuclear power station

A transient test and control method technology, applied in the field of nuclear power, can solve problems such as low execution efficiency, SOP cannot be controlled in time, and the temperature and pressure of the primary circuit drop rapidly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

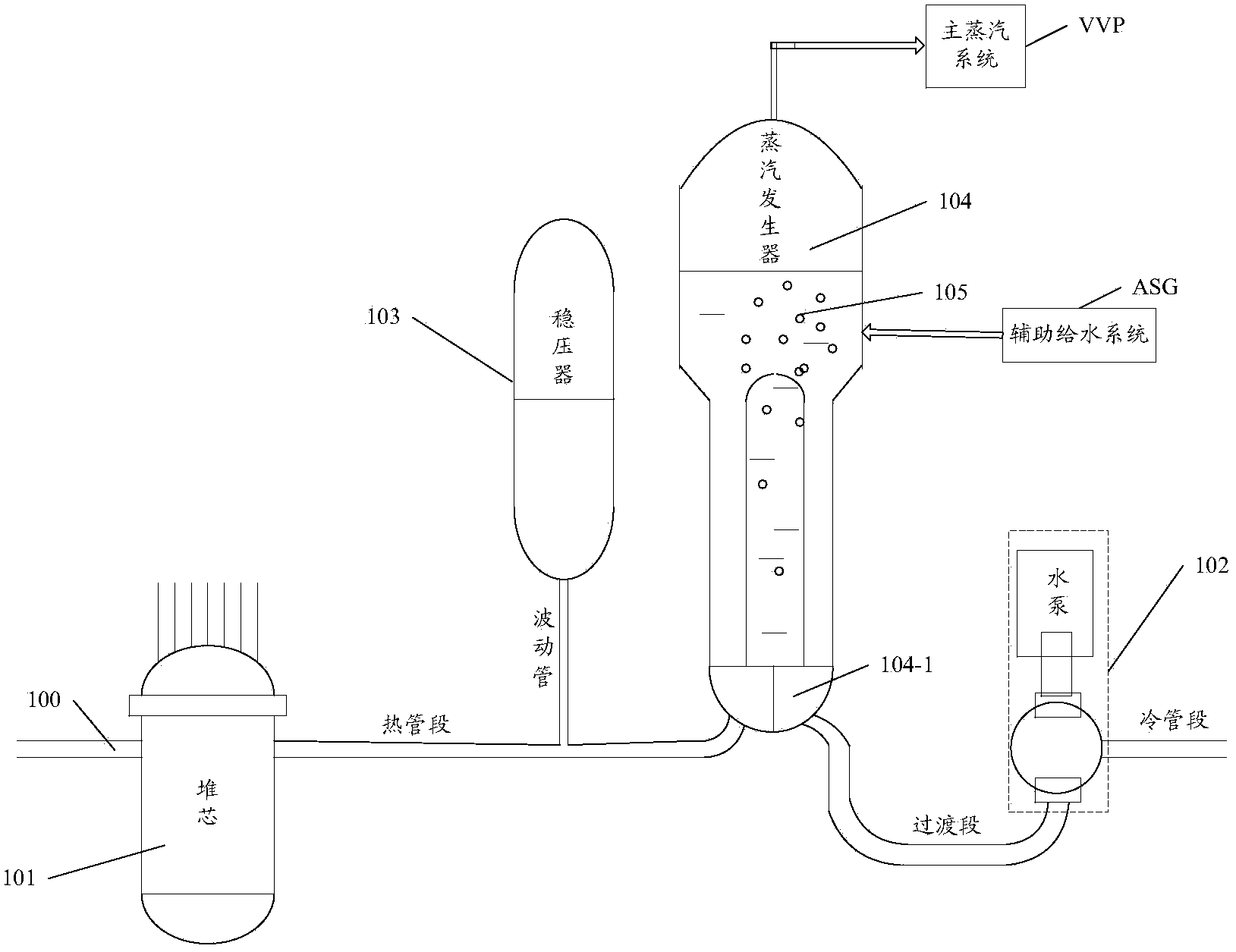

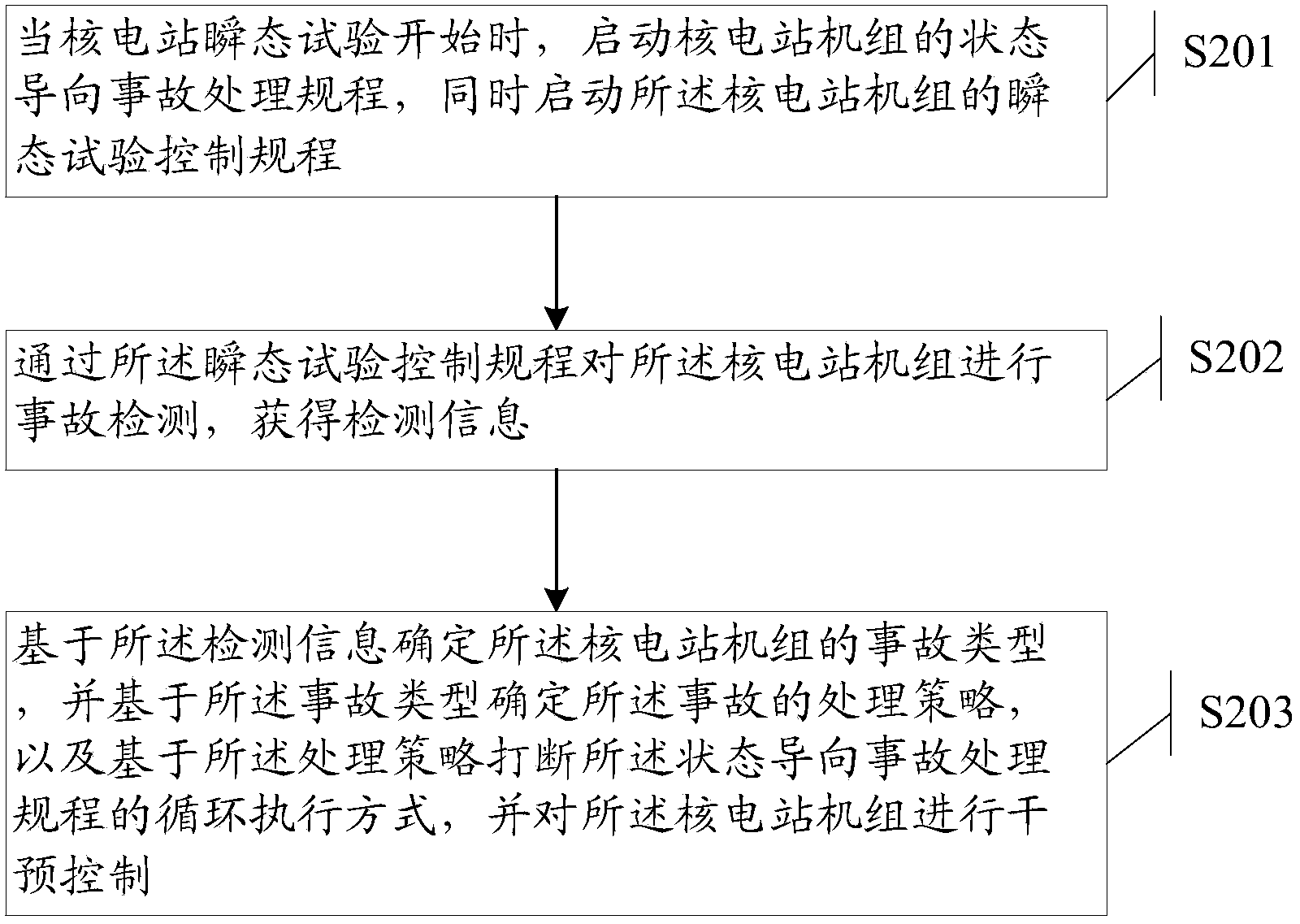

[0072] In practical applications, the primary loop system of a nuclear power plant includes three loops, please refer to figure 1 , is a structural diagram of a loop of the primary loop system, including: core 101, main pump 102, pressurizer 103, steam generator 104 (primary loop side) and various auxiliary systems; wherein, the auxiliary system includes: auxiliary The steam generator 104 releases water vapor from the main steam system VVP, the main water supply system ARE (not involved in the hot test) and the auxiliary water supply system ASG for injecting water into the steam generator 104; a loop of water 100 is injected into the primary loop pipeline, Under the power of the main pump 102, the primary circuit water 100 is driven to circulate in the primary circuit pipeline; during the circulation process, the primary circuit water 100 flows through the core 101 to take away the heat of the core, and transfers the heat to the The secondary circuit water 105 in the steam gen...

Embodiment 2

[0082] During the hot test period, the reactor is not loaded, so there is no waste heat of the core, and the heat in the primary circuit mainly comes from the heat generated by the operation of the main pump of the primary circuit. When the main pump of the primary circuit is completely shut down, the primary circuit will lose the heat source. Also can not establish natural circulation, if do not carry out relevant control operation, the average temperature and pressure in the primary loop will drop quickly, and when the primary loop is overcooled, the coolant (primary loop water) will shrink. However, in this test, the water in the primary circuit was excessively cooled and contracted, and natural circulation in the primary circuit could not be performed, which may eventually cause the pressure and temperature range of the primary circuit to exceed the operating limit, causing a transient impact on the primary circuit equipment. .

[0083] In this embodiment, a test is carrie...

Embodiment 3

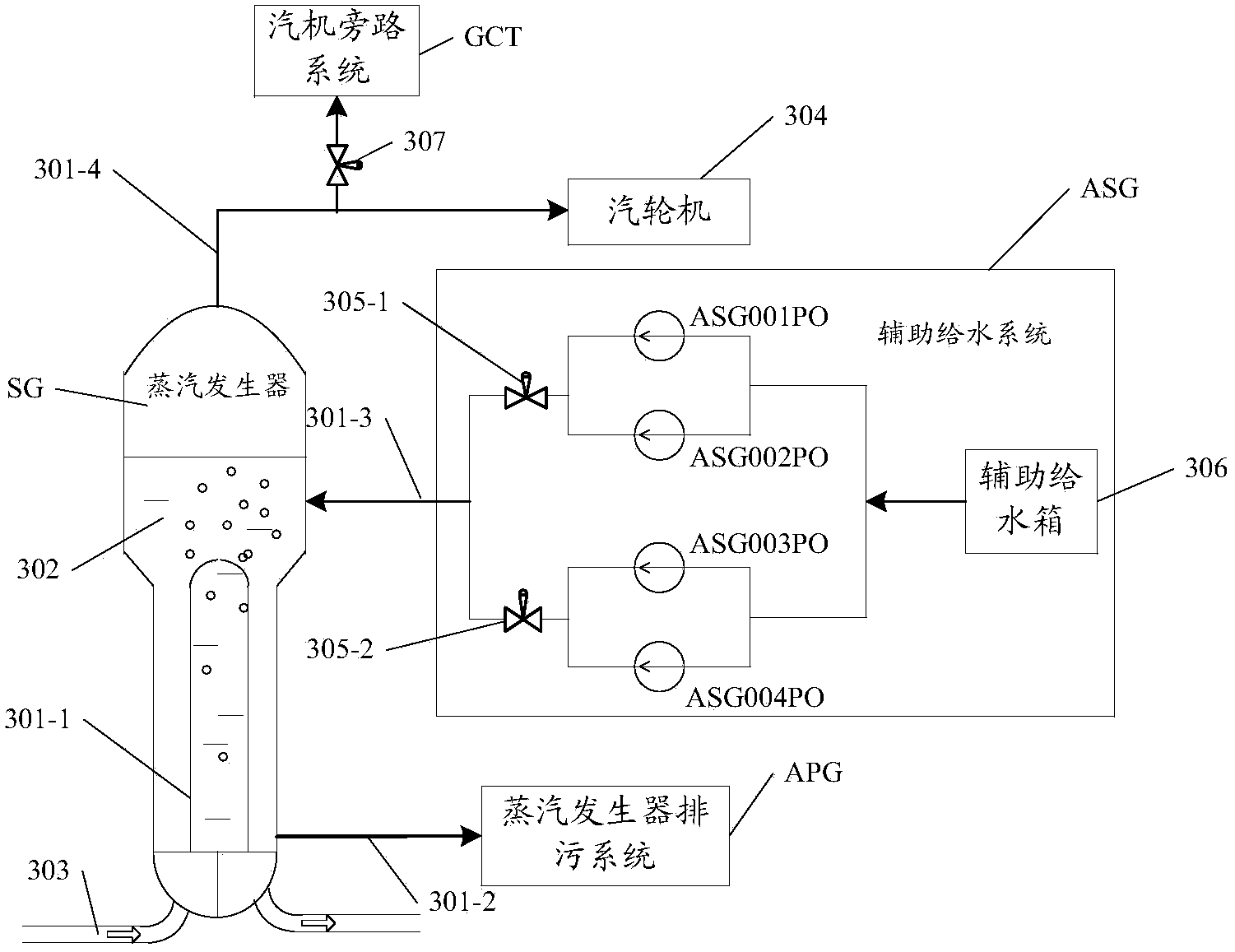

[0097] In a specific implementation process, the primary loop system includes three loops (No. 1 loop, No. 2 loop and No. 3 loop), and each loop includes a main pump and a steam generator. Specifically, No. 1 loop includes No. 1 main pump RCP001PO and No. 1 steam generator SG1; No. 2 loop includes No. 2 main pump RCP002PO and No. 1 steam generator SG2; No. 3 loop includes No. 3 main pump RCP003PO and No. No. 3 steam generator SG3; and, the three loops share an auxiliary water supply system ASG and a turbine bypass system GCT.

[0098] The primary circuit temperature and pressure control method mentioned in Example 2 is a control method applicable to the outage of the three main pumps (RCP001PO~RCP003PO). In the specific implementation process, after the power switch is successful, the main pump will be powered on again Start up and start working. During this process, care should be taken to prevent overheating of the primary circuit and overpressure of the primary circuit. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com