Slow-release film agent of isegenan

A technology of Estherglam and slow-release film, which is applied in the field of slow-release film preparations to achieve long-acting antibacterial effects, increase bioavailability, and prolong the effect of drug action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 Preparation of slow-release film of the present invention

[0039] Extended-release film prescription

[0040] The protective layer:

[0041] PVA17-88 80% Glycerin 0.8% Xylitol 0.4% Propylene Glycol 3.2% Tween 80 1% Purified Water

[0042] Drug film layer:

[0043] Estherglam 0.03% Gum Arabic 50% CMC-Na10% Glycerin 0.8% Propylene Glycol 3.2% Xylitol 0.4% Tween 80 1% Starch 3.2% Sorbic Acid 0.2% Phosphate buffer (pH6.8) added to the balance

[0044] Preparation method:

[0045] 1. Fabrication of protective layer

[0046] Wash and purify PVA17-88 repeatedly with an appropriate amount of 85% ethanol, soak in sufficient pure water overnight to fully swell, heat at 75°C to dissolve, filter, and slowly add glycerin, propylene glycol, Tween, xylitol and pure water in sequence And fully stir to make the mixture uniform, remove air bubbles, and form a film

[0047] 2. Preparation of drug film layer

[0048] ①Soak and swell CMC-Na with buffer solution at a rat...

Embodiment 2

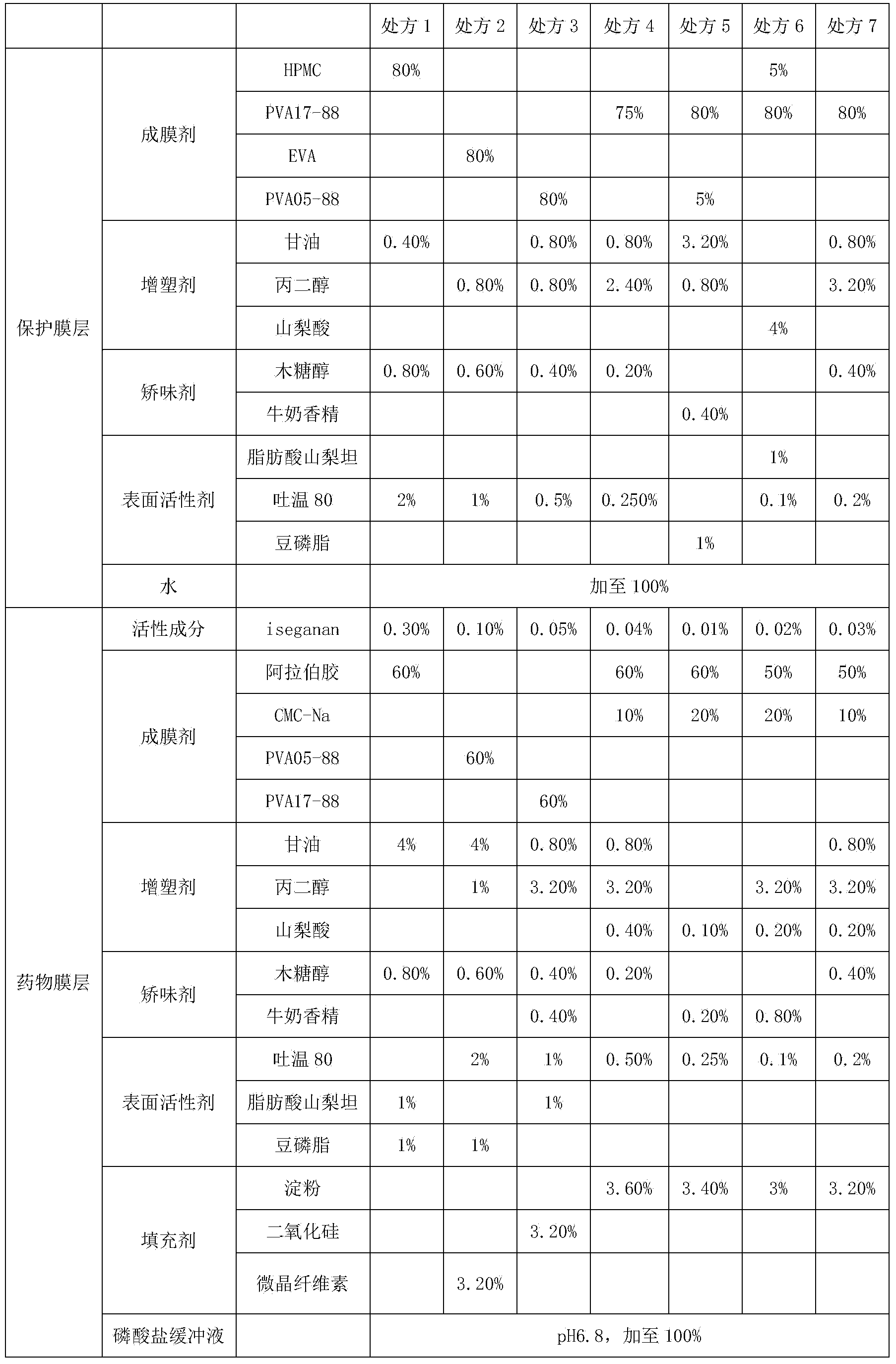

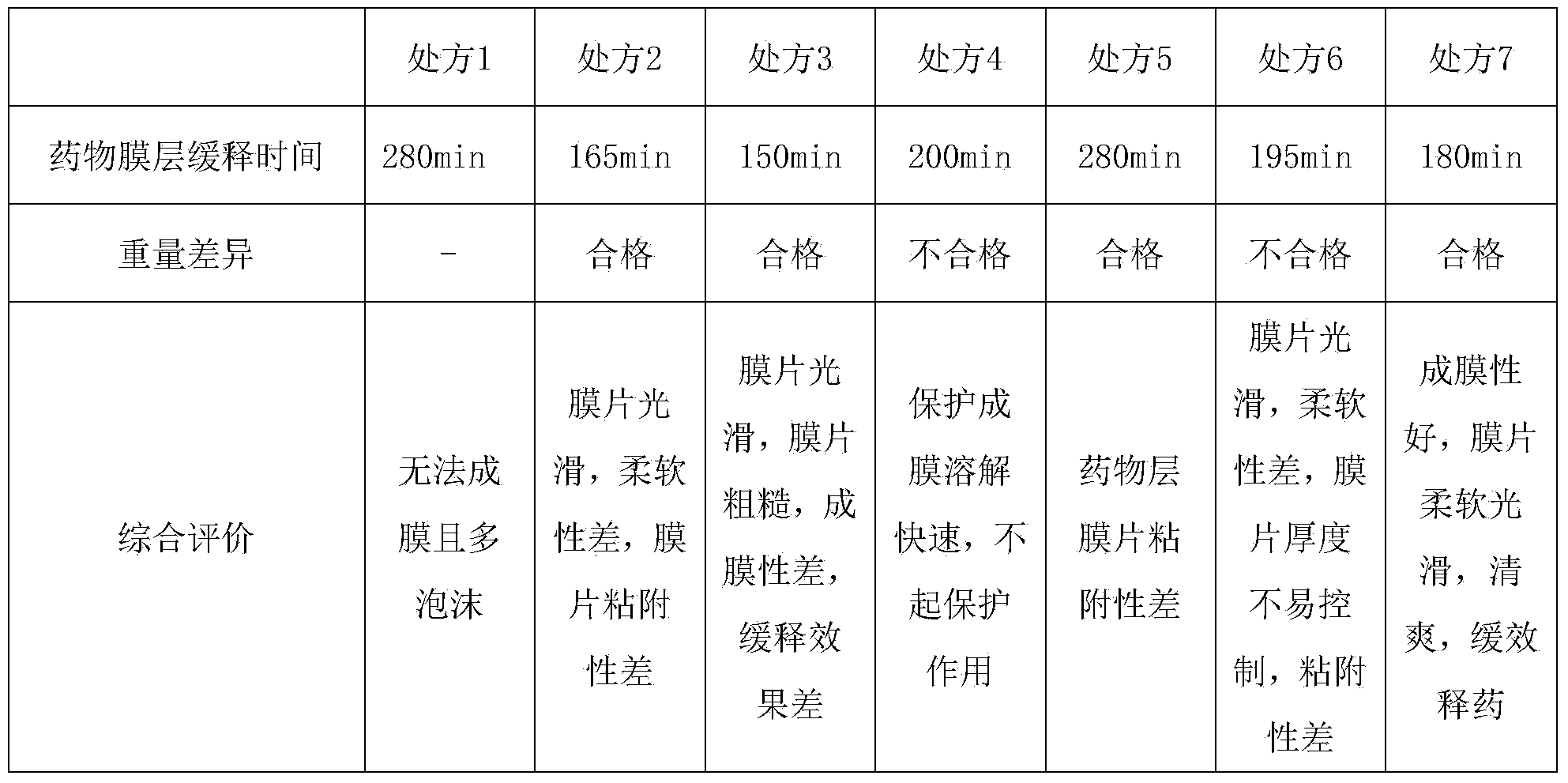

[0055] Example 2 Screening of sustained-release film formulations

[0056] According to the ratio in Table 1, the sustained-release film formulation was investigated, and the results are shown in Table 2

[0057] Table 1

[0058]

[0059] Table 2

[0060]

[0061] According to the content in the above table, only the film prepared by prescription 7 can meet the requirements, not only the sustained release time reaches 3 hours, but also the best film-forming performance, appearance and taste.

Embodiment 3

[0062] Example 3 Inspection of Weight Difference of Sustained-release Film

[0063] 1. Inspection method: Take 20 pieces of the test product, weigh them accurately, obtain the average weight, and then weigh each piece accurately. Weight per piece compared to average weight

[0064] 2. The test results are as follows

[0065] table 3

[0066]

[0067] Inspection and judgment result: qualified

[0068] 3. Release rate test of sustained-release film

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com