Technique for preventing defects of surfacing wear-resistant layer of part

A process method and wear-resistant layer technology, applied in manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems affecting the smooth delivery of products, lengthening the production cycle, poor welding processability, etc., to avoid unfused defects and reduce repairs. The number of times, the effect of improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with embodiment.

[0030] The present invention comprises the following steps:

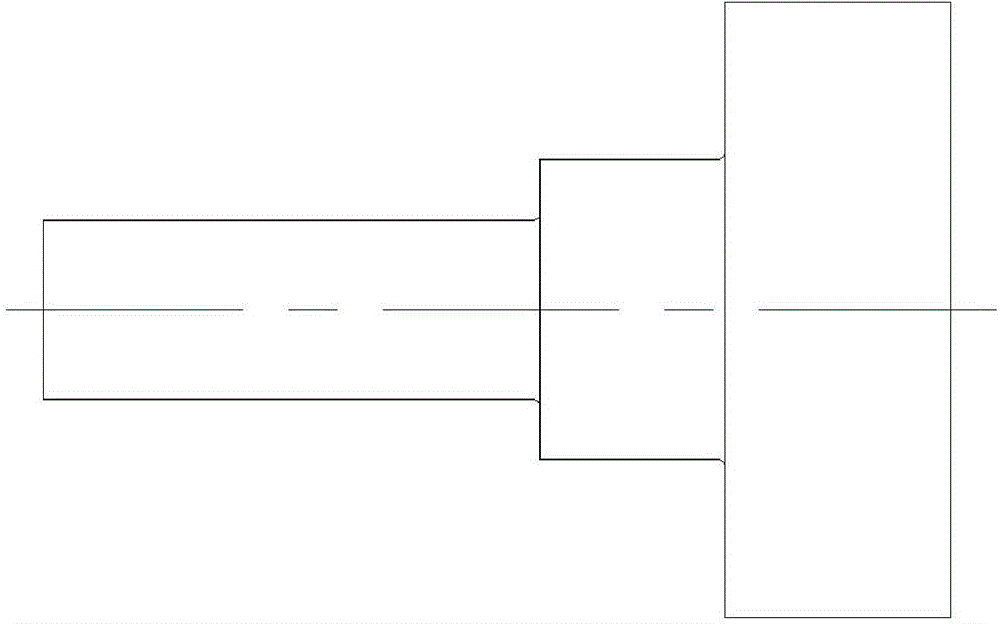

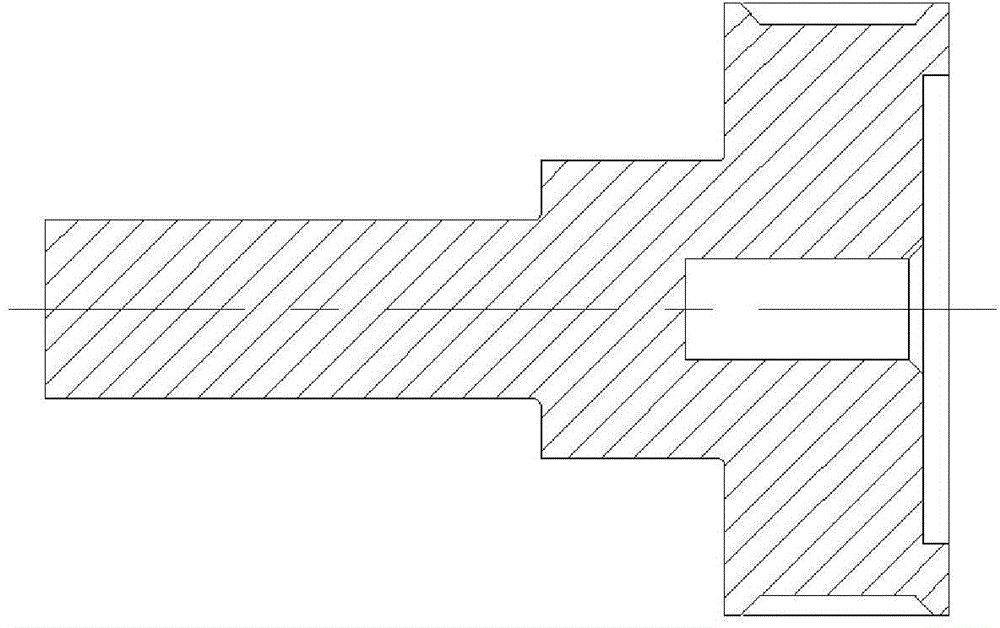

[0031] 1) see figure 1 , the shape of the piston parts is roughed, and the parts with cylindrical boss structure are obtained, see figure 2 , an annular groove is provided on the large end cylindrical surface of the part along the circumferential direction, the cross section of the annular groove is an inverted isosceles trapezoid, and the bottom chamfer of the annular groove is 133°~137°;

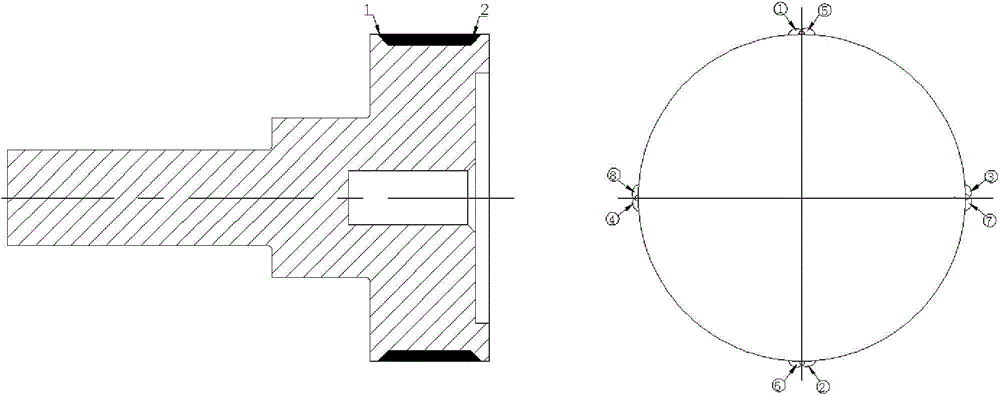

[0032] 2) Surfacing the nickel-based superalloy auxiliary layer in the annular groove of the part in step 1), the material of the nickel-based superalloy auxiliary layer is GH536, the parts need to be cleaned before welding, and the surface to be welded is dipped in acetone Wipe with absorbent cotton to remove grease, and air dry, heat the parts to 150-200°C during welding, see image 3 , using cross-symmetrical welding, using DC a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com