Black phosphorus preparation method with high conversion rate

A high-conversion, black phosphorus technology, applied in the preparation of phosphorus, electrical components, battery electrodes, etc., can solve the problems of low yield, ultra-high pressure, high toxicity, etc., and achieve simple steps, high conversion rate, and good crystallinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Mix red phosphorus, tin and tin tetraiodide in a mass ratio of 3:40:1, put them into a quartz tube, evacuate until the pressure inside the quartz tube is less than 0.05pa, seal the tube, and heat to make the temperature of the raw material end in the quartz tube The temperature was 200°C, then raised to 600°C in 1 hour, kept at 6 hours, then cooled to 300°C in 6 hours, kept at 2 days, cooled to room temperature in 10 hours, and the product was taken out.

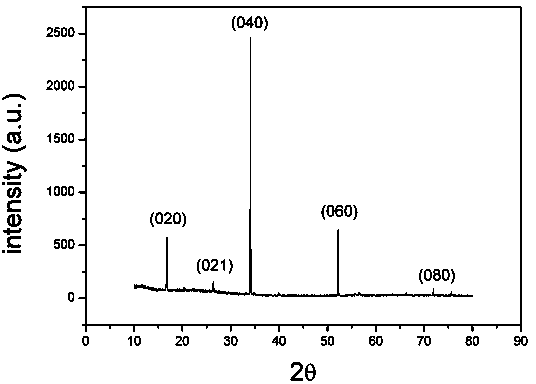

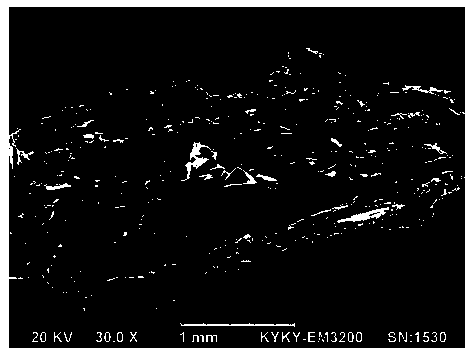

[0015] The product obtained was a black mass, figure 1 Its XRD figure, its SEM such as figure 2 As shown, it can be seen that the obtained product is black phosphorus. And after measurement, the mass of black phosphorus obtained is about 97% of the mass of red phosphorus in the raw material.

Embodiment 2

[0017] Mix red phosphorus, tin and tin tetraiodide in a mass ratio of 3: 25: 1, put them into a quartz tube, evacuate until the pressure inside the quartz tube is less than 0.05pa, seal the tube, and heat to make the temperature of the raw material end in the quartz tube It takes 2 hours to raise the temperature to 700°C, keep it warm for 10 hours, then take 8 hours to cool it down to 500°C, keep it for 3 days, then take 15 hours to cool down to room temperature, and black phosphorus is obtained in the quartz tube.

Embodiment 3

[0019] Mix red phosphorus, tin and tin tetraiodide in a mass ratio of 1:40:1, put them into a quartz tube, evacuate until the pressure inside the quartz tube is less than 0.05pa, seal the tube, and heat to make the temperature of the raw material end in the quartz tube The temperature is 100°C, then raised to 400°C in 1 hour, kept at 5 hours, then lowered to 200°C in 6 hours, kept at 1 day, lowered to room temperature in 10 hours, and black phosphorus was obtained in the quartz tube.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com