Combined carbonization method for preparing baking soda and white carbon black by matching rice hull power generation

A technology of baking soda and white carbon black, which is applied in the field of preparation of baking soda and white carbon black, can solve the problems of low activity of activated carbon, large amount of dissolved silicon dioxide, etc., and achieve increased production, low cost and no waste discharge production, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

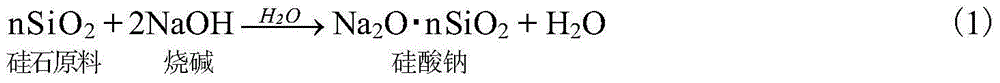

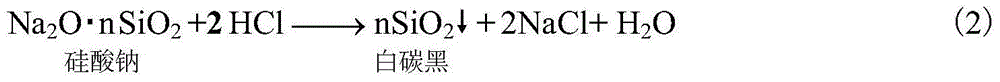

Method used

Image

Examples

Embodiment 1

[0100] (1) Preparation of sodium silicate - activated carbon

[0101] Add 1,000 grams of 20% caustic soda solution to the pressure reactor with stirring, and then add 520 grams of rice husk ash with a silicon dioxide content of 69.2%, and react at 180° C. and corresponding saturated steam pressure for 60 minutes to complete the reaction.

[0102] (2) Sodium silicate - carbon residue separation

[0103] Filter the reaction product, the filtrate is sodium silicate solution, and send it to the baking soda-white carbon black preparation process, and the filter residue is carbon residue composed of carbon particles, and send it to the next water washing process

[0104] (3) Charcoal residue washing

[0105] The charcoal residue was washed twice with water consumption of 1007 grams each time, and the water was recycled into step (2) to obtain the sodium silicate filtrate, and the charcoal residue after washing was sent to the activation process.

[0106] (4) Carbon residue activat...

Embodiment 2

[0121] (1) Preparation of sodium silicate - activated carbon

[0122] In the pressure reactor with stirring, add 520 grams of rice husk ash identical to Example 1, then add the caustic soda solution recovered in Example 1 step (5), react at 200 ° C and corresponding saturated steam pressure for 50 minutes to complete the reaction .

[0123] (2) Sodium silicate - carbon residue separation

[0124] The reaction product is filtered, and the filter residue is carbon residue composed of carbon particles, which is sent to the water washing process; the filtrate is sodium silicate solution, which is used for the preparation of baking soda-white carbon black.

[0125] (3) Charcoal residue washing

[0126] Water the charcoal slag twice first, each time the water consumption is 1014 grams, and the washing water is recovered and incorporated into the sodium silicate filtrate.

[0127] (4) Carbon residue activation

[0128] Add 74 grams of water to the washed charcoal residue, then ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com