A kind of preparation method of germanium oxide nanowire

A technology of germanium oxide and nanowires, which is applied in the field of preparation of germanium oxide nanowires, can solve the problems of high synthesis cost, waste of reaction solution, harsh reaction conditions, etc., and achieve easy control of the reaction process, low environmental pollution, and low preparation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of germanium oxide nanowires, the specific operation steps are as follows:

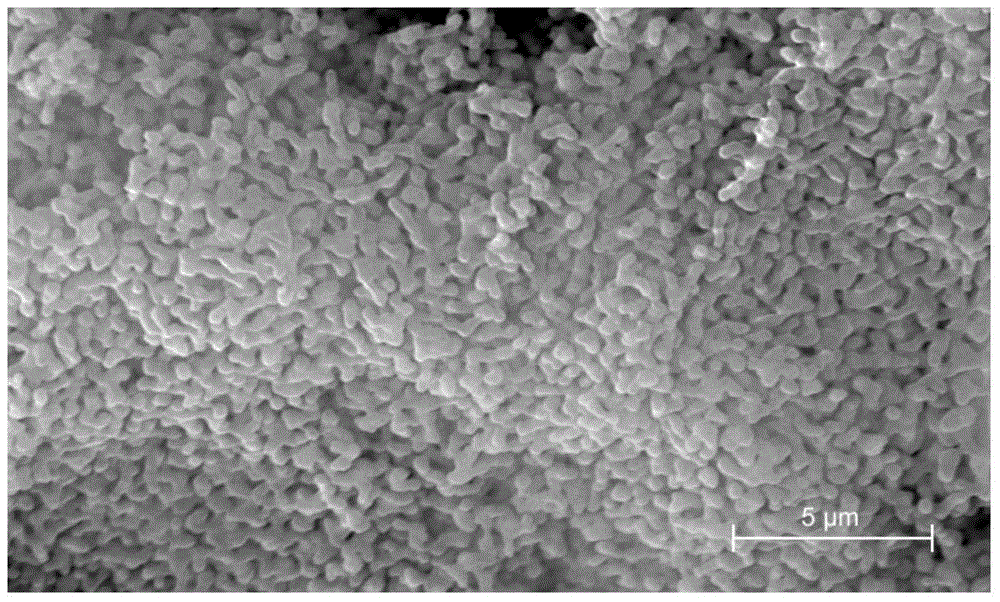

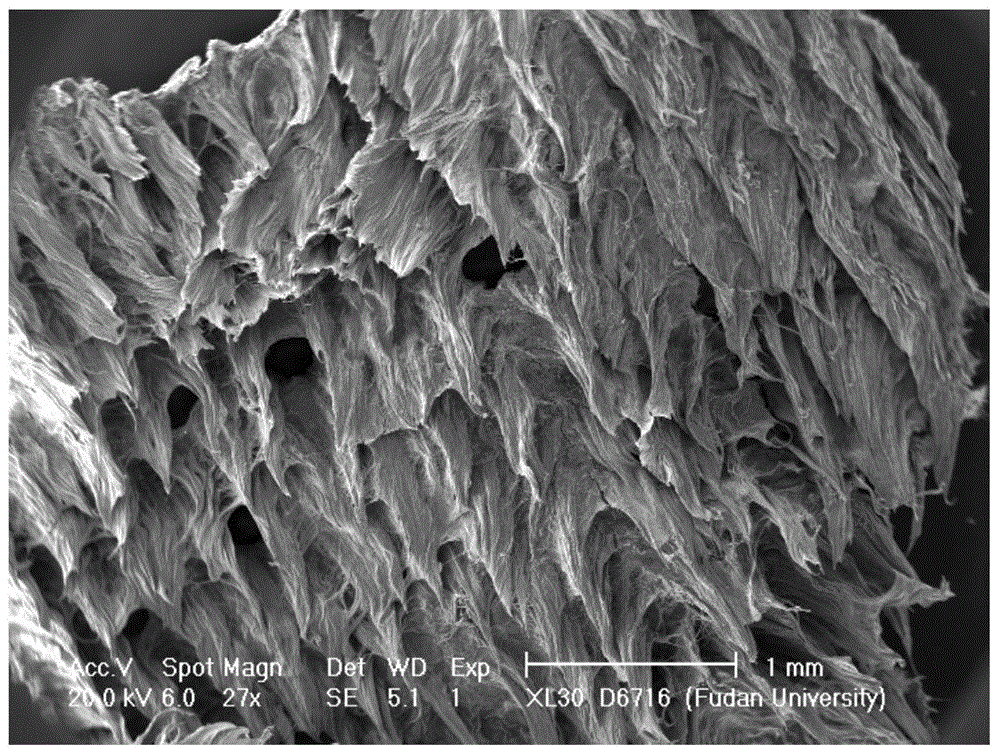

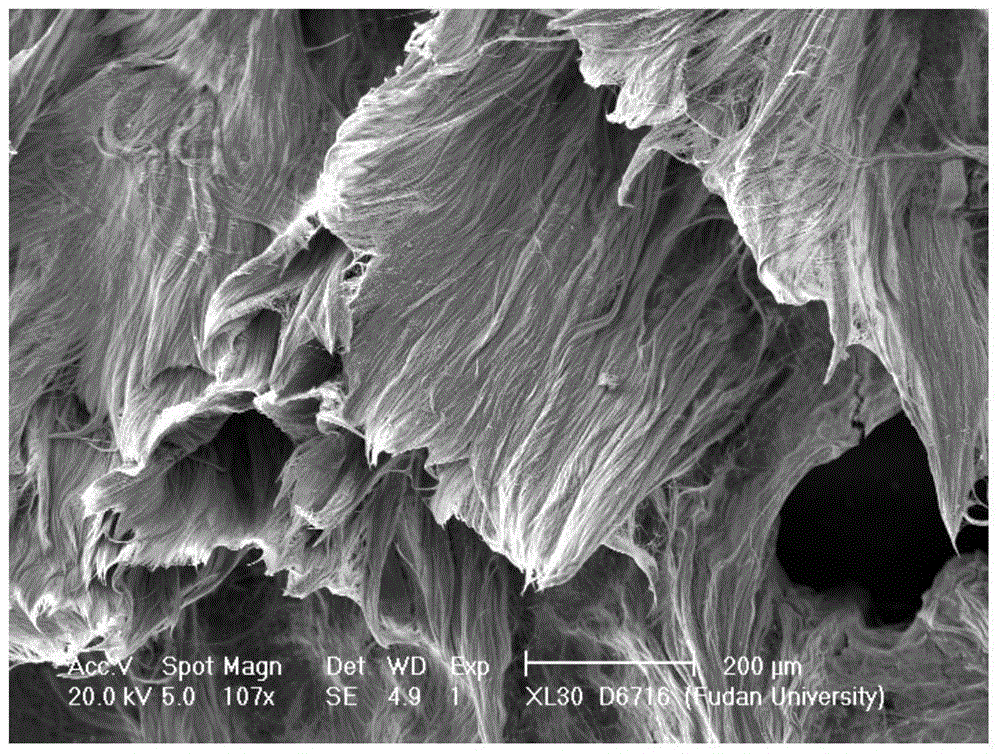

[0030] Disperse 0.1g of germanium oxide powder A1 in 5ml of 0.5mol / l cobalt nitrate solution and soak for 12h to obtain A2; pour A2 into a reaction kettle lined with polytetrafluoroethylene, and then inject 4ml of ethylenediamine into the bottom of the kettle , tighten the reactor and place it in an oven at 200°C for 5 days, take out the red solid at the bottom of the reactor; wash the obtained red solid three times with absolute ethanol and then three times with water to remove ethylenediamine, after cleaning, put it at 90°C Drying in an oven gave product A3.

Embodiment 2

[0032] The 0.1 g of germanium oxide powder A1 in Example 1 was replaced with 0.1 g of germanium powder, and the rest of the operation steps were the same as in Example 1 to obtain the product B2.

Embodiment 3

[0034] The drying temperature in Example 1 was changed from 90°C to 140°C, and the rest of the operation steps were the same as in Example 1 to obtain product C3, which had no nanowire morphology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com