Porous molybdenum trioxide as well as preparation method, hydrogenation catalyst and dehydrogenation catalyst thereof

A dehydrogenation catalyst, hydrogenation catalyst technology, applied in the direction of molybdenum oxide/molybdenum hydroxide, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the complex preparation process of molybdenum trioxide, Inability to mass production and other problems, to achieve the effect of good repeatability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] As introduced in the background technology section, the preparation of molybdenum trioxide in the prior art has the problems of complicated process and incapable of large-scale production. In order to solve this problem, the present invention provides a method for preparing porous molybdenum trioxide, which includes the following steps: S1, preparing an aqueous solution containing molybdenum soluble acid and / or molybdenum soluble salt; S2, adding three-dimensional A template material with a cubic mesoporous structure to obtain a mixture; S3, drying and calcining the mixture to obtain a calcined product; and S4, removing the template material in the calcined product to obtain porous molybdenum trioxide.

[0027] In the above preparation method provided by the present invention, the template material having a three-dimensional cubic mesoporous structure can absorb molybdenum-containing soluble acid and / or molybdenum-containing soluble salt in three-dimensional cubic mesopo...

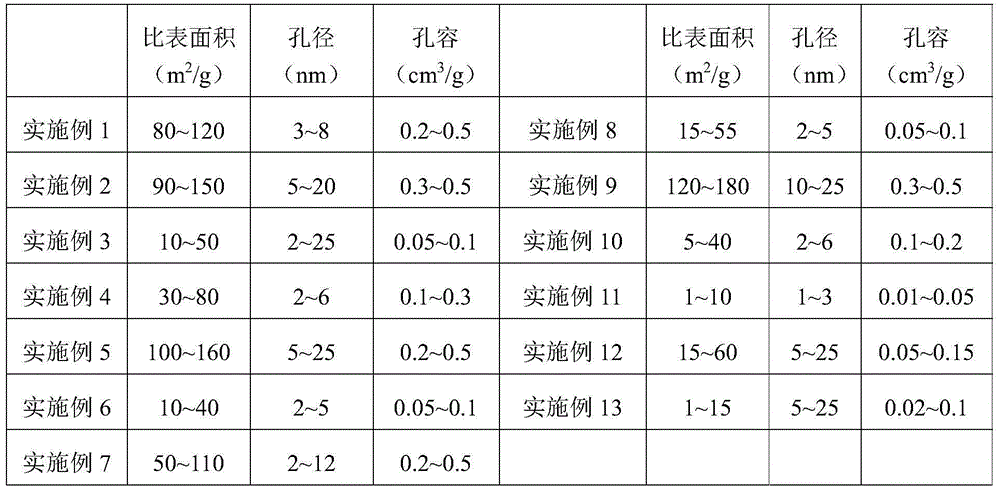

Embodiment 1 to Embodiment 13

[0053] Example 1 to Example 13 prepared porous molybdenum trioxide

Embodiment 1

[0055] Get 10g of molybdic acid and dissolve it in 30ml of distilled water, add 10g of SBA-16 (the specific surface area is 1000m 2 / g, the pore volume is 0.9cm 3 / g, pore diameter is 10nm) and fully mixed and stirred to obtain the mixture; the mixture was dried, then heated to 400°C for calcination in a muffle furnace (the heating rate was 5°C / min), and after cooling to room temperature, the calcined product was obtained; The template material is removed by hydrofluoric acid aqueous solution with a mass concentration of 2%, and then centrifuged and washed several times with distilled water, and dried to obtain porous molybdenum trioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com