Method for preparing molybdenum disulfide nanosheets by ultrasonic-assisted chemical intercalation

A molybdenum disulfide, nanosheet technology, applied in the direction of molybdenum sulfide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of harsh conditions, slow speed, complicated operation, etc., and achieve good dispersion state and thickness. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

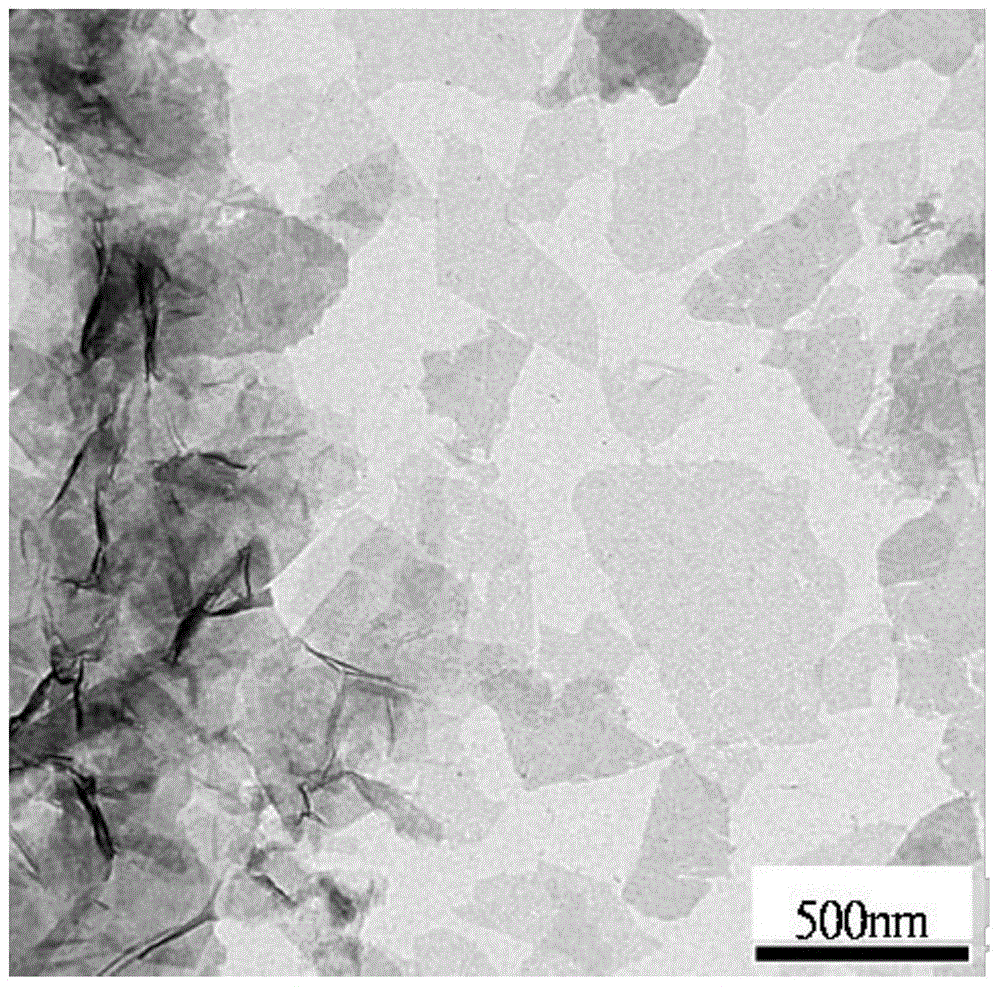

Embodiment 1

[0028] (a) Ultrasound-assisted lithium intercalation

[0029] Add 200mg of molybdenum disulfide powder into a 25ml Schlenk tube, remove the air in the reaction tube with high-purity argon and then seal it, and slowly add 6.25ml of n-butyllithium (2.4M) solution dropwise. Ultrasonic reaction at room temperature for 40 min.

[0030] (b) Stripping of molybdenum disulfide

[0031] Stop the reaction, let it stand for 30 minutes, remove unreacted n-butyllithium, add 5ml of pre-deoxygenated ultrapure water to the reaction tube, continue the reaction under ultrasonic conditions for 0.5h, and peel off to obtain the crude product of molybdenum disulfide nanosheets.

[0032] (c) Ethanol cleaning

[0033] Measure 5ml of absolute ethanol and mix it with the obtained suspension of molybdenum disulfide nanosheets. Centrifuge at 12000rpm for 10min, discard the supernatant, and collect the product at the bottom of the centrifuge tube; use 10ml of absolute ethanol to make a 20mg / ml suspensio...

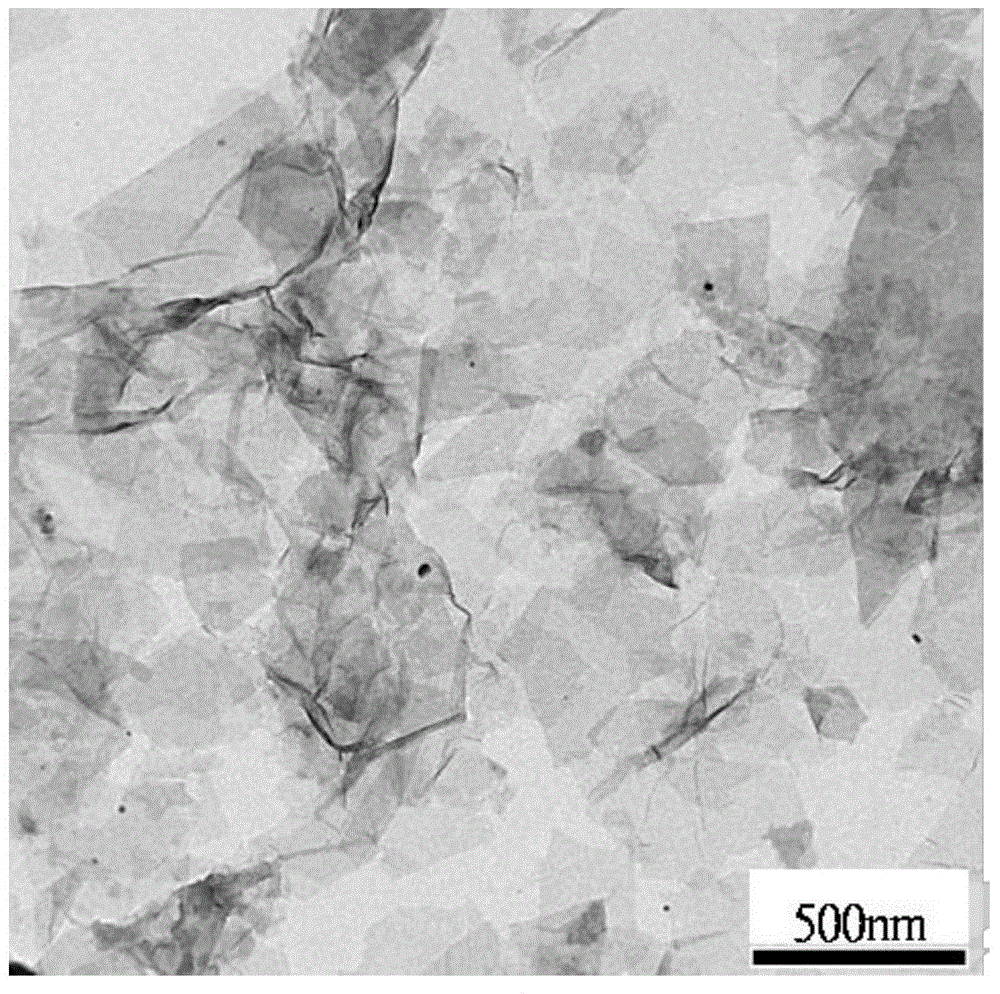

Embodiment 2

[0037] (a) Ultrasound-assisted lithium intercalation

[0038] Add 200mg of molybdenum disulfide powder into a 25ml Schlenk tube, remove the air in the reaction tube with high-purity argon and then seal it, and slowly add 1.04ml of n-butyllithium (2.4M) solution dropwise. Ultrasonic reaction at room temperature for 1 h.

[0039] (b) Stripping of molybdenum disulfide

[0040] Stop the reaction, let it stand for 30 minutes, remove unreacted n-butyllithium, add 10ml of pre-deoxygenated ultrapure water to the reaction tube, continue the reaction under ultrasonic conditions for 0.5h, and peel off to obtain the crude product of molybdenum disulfide nanosheets.

[0041] (c) Ethanol cleaning

[0042]Measure 10ml of absolute ethanol and mix it with the obtained suspension of molybdenum disulfide nanosheets. Centrifuge at 10,000rpm for 20min, discard the supernatant, and collect the product at the bottom of the centrifuge tube; use 20ml of absolute ethanol to make a 10mg / ml suspension...

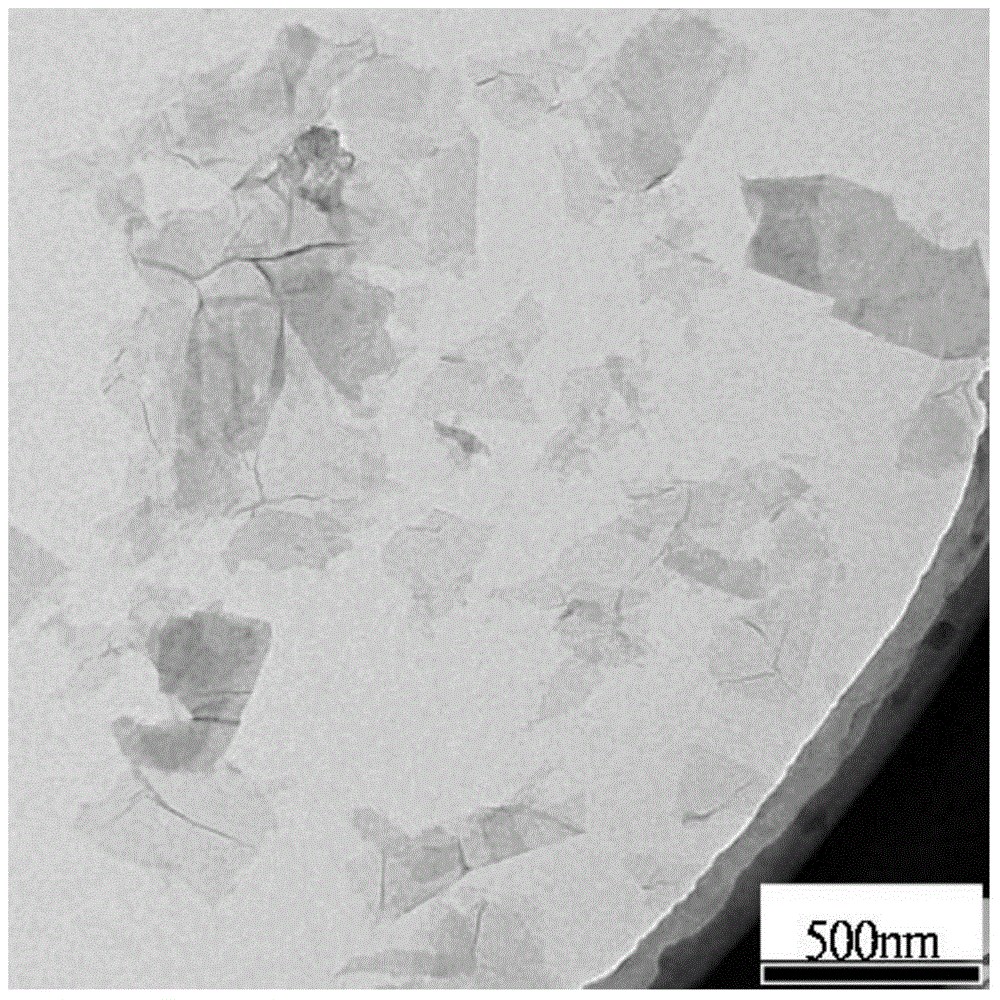

Embodiment 3

[0046] (a) Ultrasound-assisted lithium intercalation

[0047] Add 200mg of molybdenum disulfide powder into a 25ml Schlenk tube, remove the air in the reaction tube with high-purity argon and then seal it, and slowly add 1.04ml of n-butyllithium (2.4M) solution dropwise. Ultrasonic reaction at room temperature for 3h.

[0048] (b) Stripping of molybdenum disulfide

[0049] Stop the reaction, let it stand for 30 minutes, remove unreacted n-butyllithium, add 10ml of pre-deoxygenated ultrapure water to the reaction tube, continue the reaction under ultrasonic conditions for 0.5h, and peel off to obtain the crude product of molybdenum disulfide nanosheets.

[0050] (c) Ethanol cleaning

[0051] Measure 10ml of absolute ethanol and mix it with the obtained suspension of molybdenum disulfide nanosheets. Centrifuge at 11000rpm for 15min, discard the supernatant, and collect the product at the bottom of the centrifuge tube; use 20ml of absolute ethanol to make a 10mg / ml suspension,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com