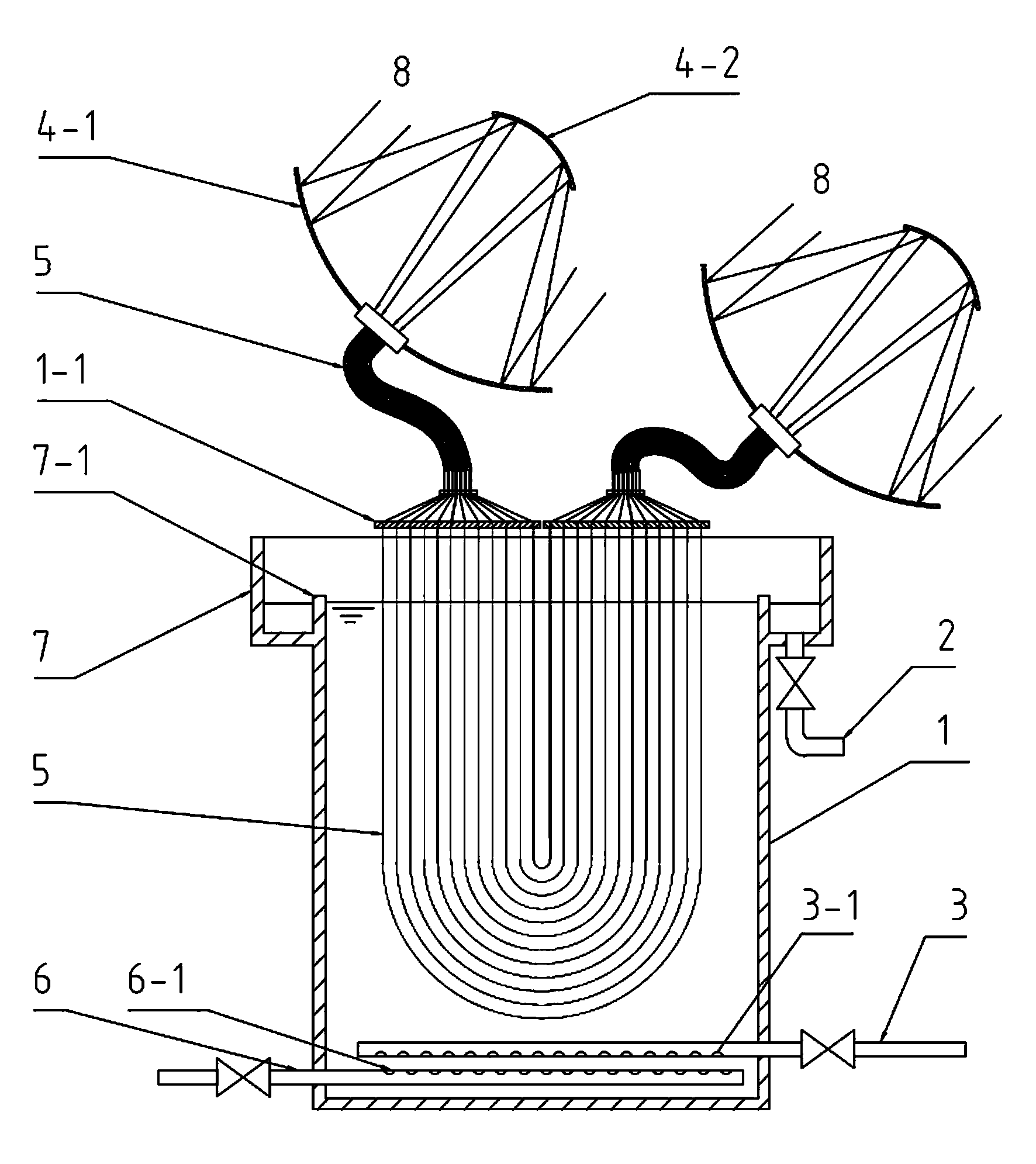

Method for processing wastewater by using photocatalytic reaction, and photocatalytic reactor

A photocatalytic reactor and photocatalytic reaction technology, applied in chemical instruments and methods, special compound water treatment, light water/sewage treatment, etc., can solve problems such as restricting the application scope of the reactor, complex structure, etc. , the effect of high reaction efficiency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

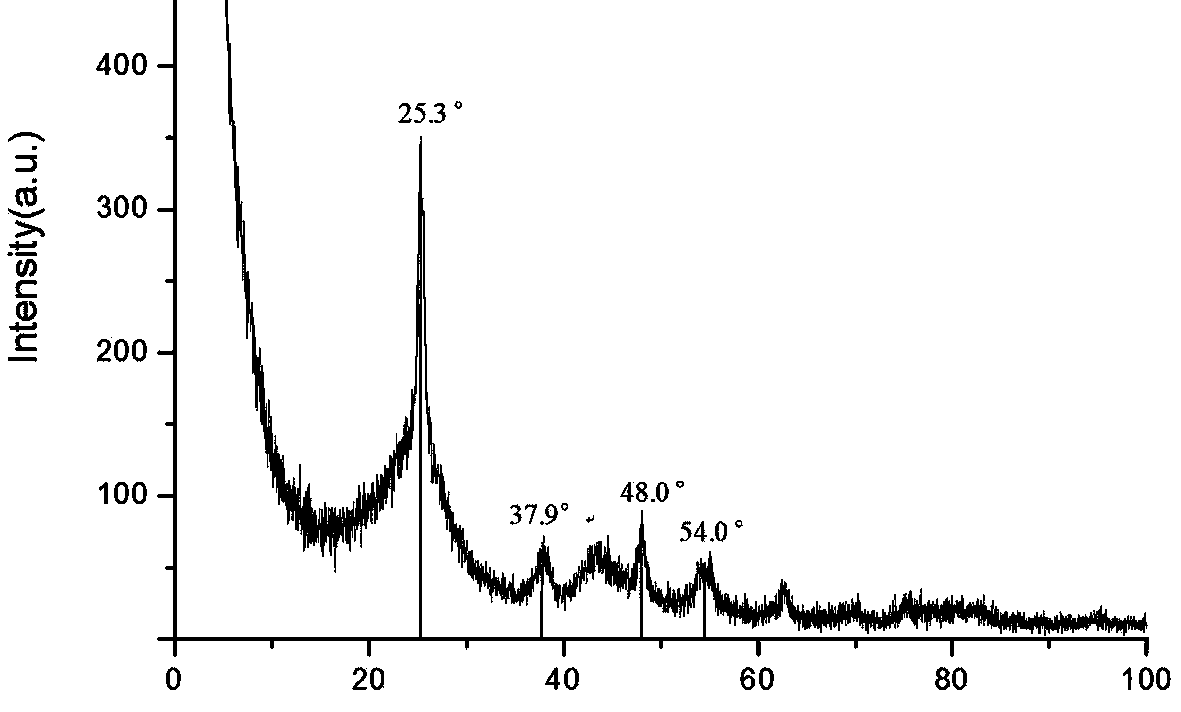

[0042] Example 1 Immobilized TiO with Activated Carbon as Carrier 2 preparation of

[0043] 1. Vector pretreatment

[0044] The main function of the oxidation treatment of activated carbon is to introduce oxygen-containing functional groups on the surface. It has been confirmed that when activated carbon is used as a metal catalyst carrier, the oxygen-containing functional groups on the surface of activated carbon can become active adsorption sites for certain metal ions. In the present invention, liquid-phase oxidation is used. This method can not only introduce oxygen-containing functional groups, but also remove ash from activated carbon.

[0045] The specific operation steps are as follows:

[0046] (1) First weigh an appropriate amount of activated carbon carrier, put it into a conical flask, add an appropriate amount of distilled water, and then stir evenly for 20 minutes;

[0047] (2) Put the activated carbon in the previous step into the ultrasonic cleaner, an...

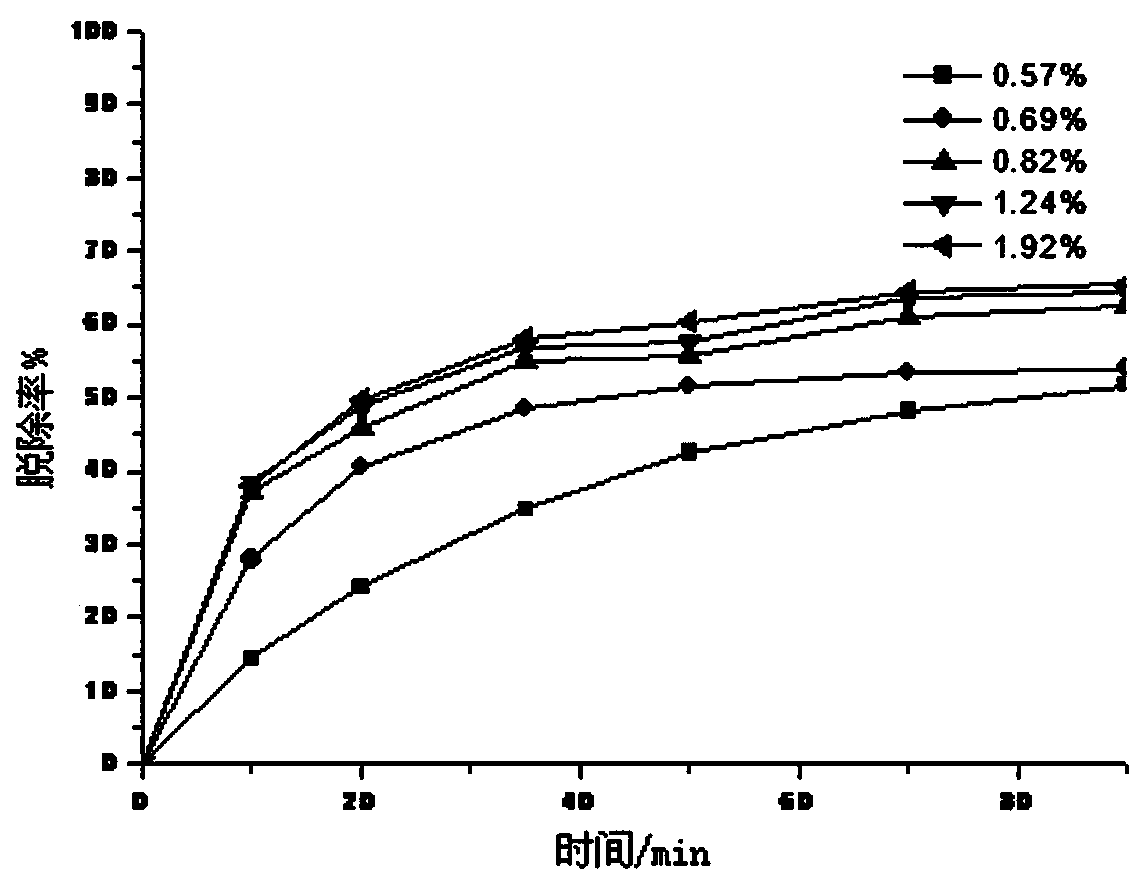

Embodiment 2~6

[0058] Prepare TiO with the method for embodiment 1 2 Immobilized TiO with different loads 2 , use 35-55 mesh granular activated carbon, control the amount of impregnating liquid and the number of impregnating times, and prepare different TiO 2 The particles of the loading amount are shown in Table 1.

[0059] Table 1 Immobilized TiO of Examples 2~6 2 load capacity

[0060]

Embodiment 7

[0061] Example 7 Immobilized La-TiO with Activated Carbon as Carrier 2 preparation of

[0062] The pretreatment of the carrier is the same as that in Example 1.

[0063] 2. Preparation of sol

[0064] (1) Take out 1.1ml glacial acetic acid (A.R.), 1ml deionized H 2 O and 15ml absolute ethanol (A.R.). Slowly add glacial acetic acid dropwise to 1 ml of deionized H2O with stirring 2 O and 15ml of absolute ethanol to configure A solution.

[0065] (2) Take out 15ml of absolute ethanol (A.R.), 6ml of Ti (C 4 h 9 o) 4 , and 1 ml of glacial acetic acid (A.R.). 6ml of Ti(C 4 h 9 o) 4 Slowly add it dropwise into the mixed solution of 15ml of absolute ethanol and 1ml of glacial acetic acid under uniform stirring, and stir for 20min, add the metal modifier lanthanum nitrate to obtain a uniform and transparent B solution.

[0066] (3) Use a constant temperature magnetic stirrer to slowly add the A solution that has been moved to the constant pressure funnel into the B so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com