Anti-corrosive and rust-resisting concrete compensation agent and preparation method

A technology of concrete and compensating agent, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of reduced service life of concrete components, unsatisfactory use effect, ecological environment hazards, etc., to prolong the service life , Improve the ability to resist freezing and thawing cycle damage, and have strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

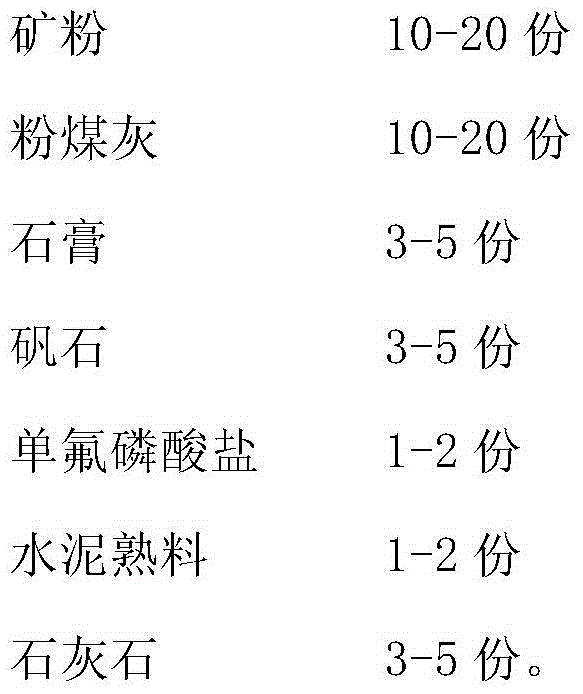

[0036] A concrete anti-corrosion and anti-rust compensation agent, comprising the following components according to the mass fraction ratio:

[0037]

[0038] The application of the above example products improves the strength of concrete at various ages in seawater or polluted water environments, and under the effect of effective resistance to chloride ion penetration, the electric flux and chloride ion diffusion coefficient of concrete at all ages are significantly reduced.

example 2

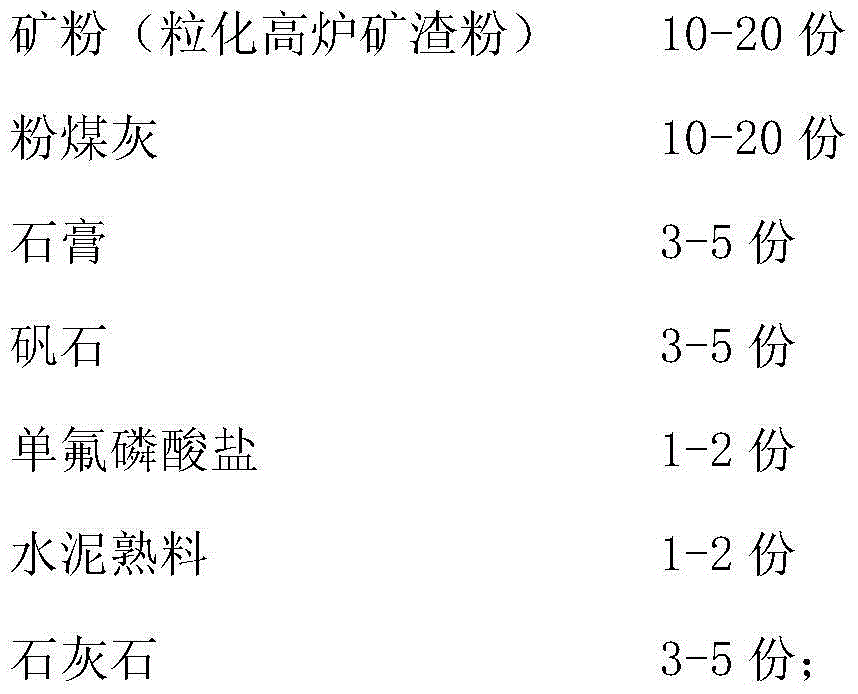

[0040] A concrete anti-corrosion and anti-rust compensation agent, comprising the following components according to the mass fraction ratio:

[0041]

[0042]

[0043] Both the slag powder (granulated blast furnace slag powder) and the fly ash have a specific surface area of 350-400m 2 / kg of powdery solid.

[0044] The potassium monofluorophosphate is a powdery solid of 200-300 mesh.

[0045] The gypsum, alum stone, cement clinker and limestone are all massive solids with a particle diameter of 20-40 mm.

[0046] The above example is a preferred example of the present invention. The example products have improved the strength of concrete at various ages in seawater or polluted water environments, and the compressive strength ratios of 3 days, 7 days, and 28 days have reached 104%, 111% and 108% respectively . Under the effect of effective anti-chloride ion penetration, the electric flux and chloride ion diffusion coefficient of concrete of all ages are significantl...

example 3

[0048] A concrete anti-corrosion and anti-rust compensation agent, comprising the following components according to the mass fraction ratio:

[0049]

[0050] The application of the above example products has improved the strength of concrete at various ages in seawater or polluted water environments, and under the effect of effective resistance to chloride ion penetration, the electric flux and chloride ion diffusion coefficient of concrete at all ages have been significantly reduced. It has obvious anti-rust effect on metal components in concrete, prolonging the service life of metal components.

[0051] The preparation method of the above-mentioned concrete anti-corrosion and anti-rust compensator comprises steps as follows:

[0052] (1) Raw material preparation, including a specific surface area of 350-400m 2 / kg of powdered mineral powder (granulated blast furnace slag powder) and fly ash, 200-300 mesh monofluorophosphate, and massive gypsum, alum stone, cement clin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com