Method for manufacturing high-phosphorus iron by using shaft furnace to directly reduce high phosphorus ore

A high-phosphate rock and shaft furnace technology, applied in the field of metallurgy, can solve the problems of not being suitable for shaft furnaces and increasing costs, and achieve the effects of energy saving, cost saving, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

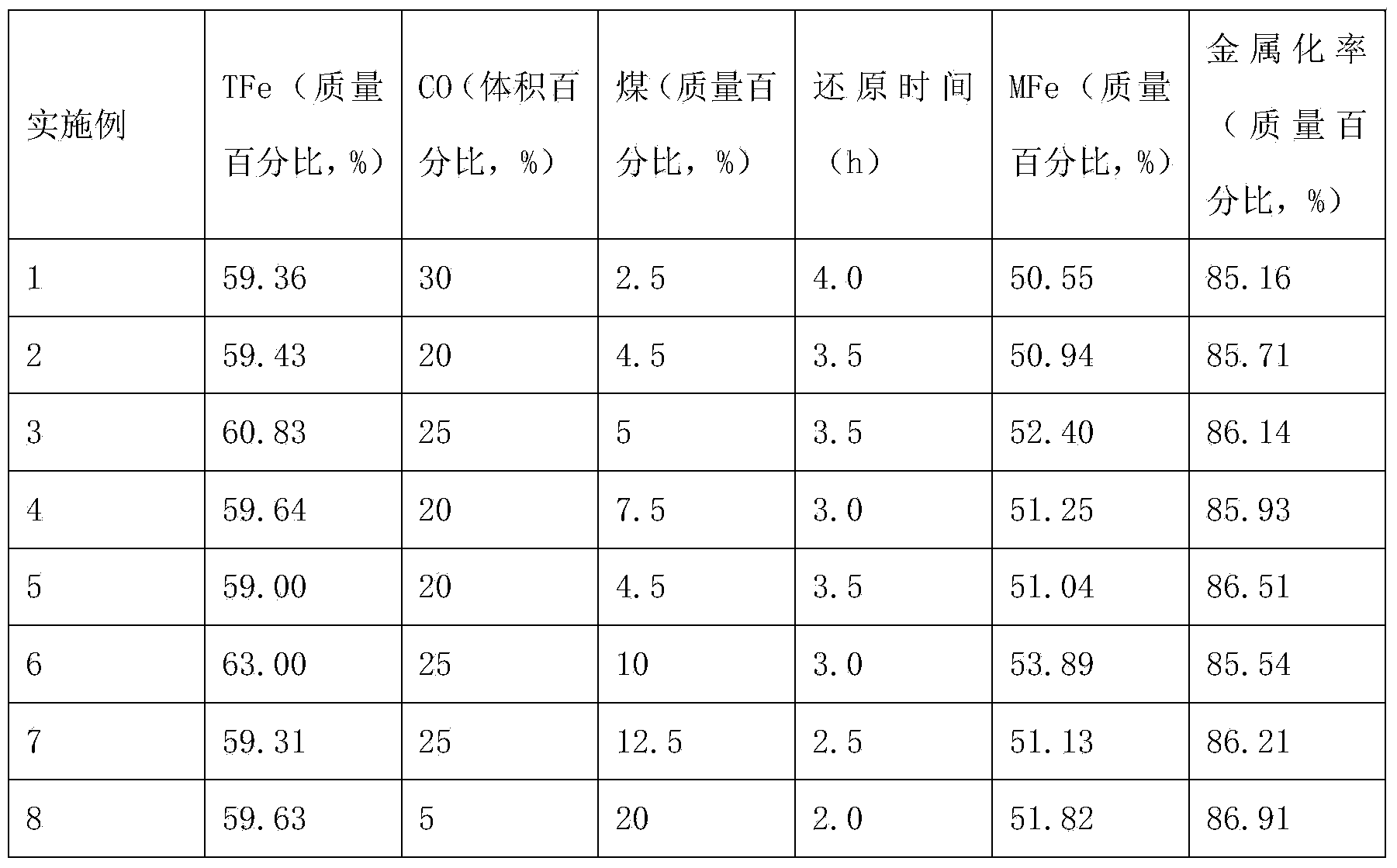

Embodiment 1

[0018] A method for directly reducing high-phosphate ore with a shaft furnace, the steps comprising:

[0019] (1) Get 49 parts of high-phosphorus rock powder, 1 part of bentonite, 2.5 parts of coal powder, and the particle size of each component is less than or equal to 0.074 mm, accounting for more than 60%;

[0020] (2) Pour the raw materials on the pelletizing tray after batching, spray atomized water with a water content of 10%, and manually press them into pellets;

[0021] (3) Carry out the reduction reaction at 1000° C. for 4 hours in the fixed bed of the shaft furnace, and the reduction reaction uses CO and N 2 In the mixed gas atmosphere, CO accounts for 30% of the gas volume.

Embodiment 2

[0023] A method for directly reducing high-phosphate ore with a shaft furnace, the steps comprising:

[0024] (1) Get 49 parts of high-phosphate rock powder, 1 part of bentonite, 4.5 parts of coal powder, and the particle size of each component is less than or equal to 0.074 mm, accounting for more than 60%;

[0025] (2) Pour the raw materials on the pelletizing tray after batching, spray atomized water with a water content of 10%, and manually press them into pellets;

[0026] (3) Carry out the reduction reaction at 1000° C. for 3.5 hours in the fixed bed of the shaft furnace, and the reduction reaction uses CO and N 2 In the mixed gas atmosphere, CO accounts for 20% of the gas volume.

Embodiment 3

[0028] A method for directly reducing high-phosphate ore with a shaft furnace, the steps comprising:

[0029] (1) Get 49 parts of high-phosphate rock powder, 1 part of bentonite, and 5 parts of coal powder, and the particle size of each component is less than or equal to 0.074 mm, accounting for more than 60%;

[0030] (2) Pour the raw materials on the pelletizing tray after batching, spray atomized water with a water content of 10%, and manually press them into pellets;

[0031] (3) Carry out the reduction reaction at 1000° C. for 3.5 hours in the fixed bed of the shaft furnace, and the reduction reaction uses CO and N 2 In the mixed gas atmosphere, CO accounts for 25% of the gas volume.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com