A corrosion-resistant sucker rod and its manufacturing method

A sucker rod, corrosion-resistant technology, applied in the direction of drill pipe, earthwork drilling, drilling equipment, etc., can solve the problems of not being suitable for large-scale use, high price, etc., and achieve low production cost, high output-input ratio, durable Effect of improving corrosion performance and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

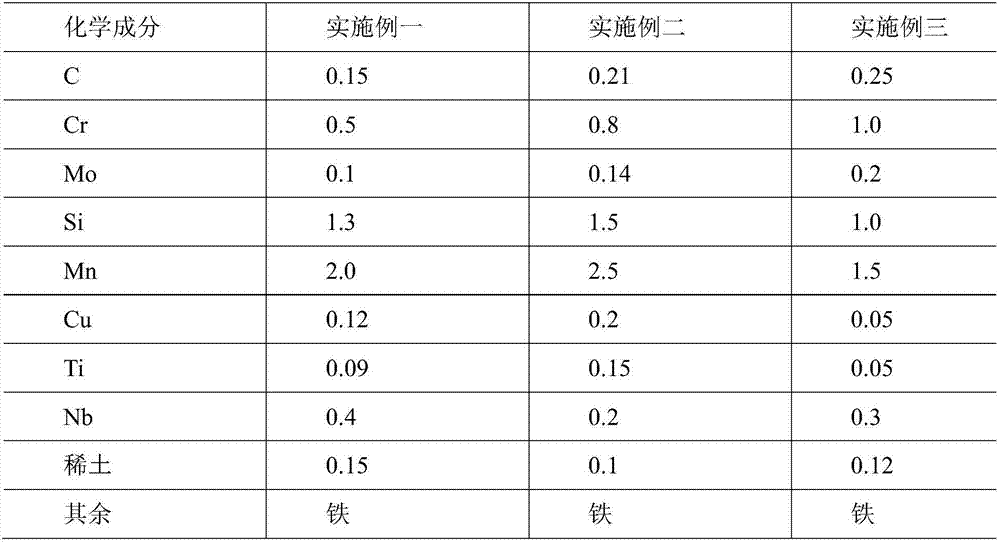

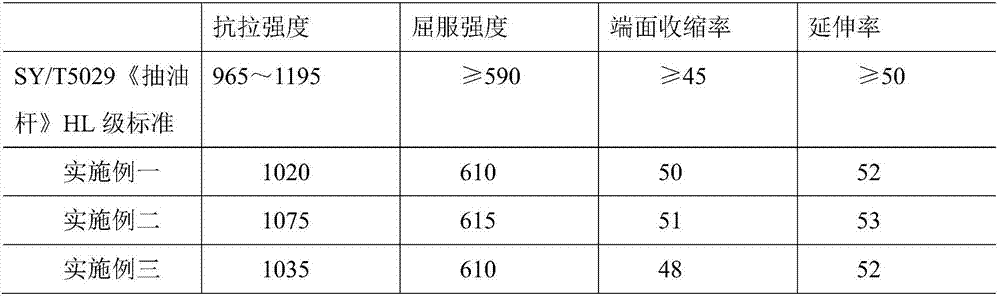

[0018] A corrosion-resistant sucker rod of the present invention comprises a rod body; in terms of mass percentage, the material composition of the rod body is: C 0.15%-0.25%; Cr 0.5%-1.0%; Mo 0.1%-0.2%; Si 1.0 %~1.5%; Mn 1.5%~2.5%; Cu 0.05%~0.2%; Ti 0.05%~0.15%; Nb 0.2%~0.4%; rare earth 0.1%~0.15%; Ce mixture.

[0019] Determination of part element content in a kind of corrosion-resistant sucker rod of the present invention is as follows:

[0020] C: It is generally believed that the carbon content of 0.08% to 0.4% has no obvious effect on the hydrogen sulfide corrosion cracking susceptibility of steel. Carbon is the main element to improve the strength of steel. To ensure a certain strength, a certain carbon content is necessary, but carbon is not good for plasticity, and at the same time, a carbon content greater than 0.3% is not good for welding. Controlling the carbon content of 0.15% to 0.25% can ensure sufficient strength, and at the same time make the steel have good...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com