Full-silicon MEMS (micro-electromechanical system) methane sensor, gas detection application and preparation method of full-silicon MEMS methane sensor

A methane sensor and silicon layer technology, which is applied in the manufacture of microstructure devices, processes for producing decorative surface effects, coatings, etc., can solve problems that cannot be used for detection and alarm, poor consistency, and difficult mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

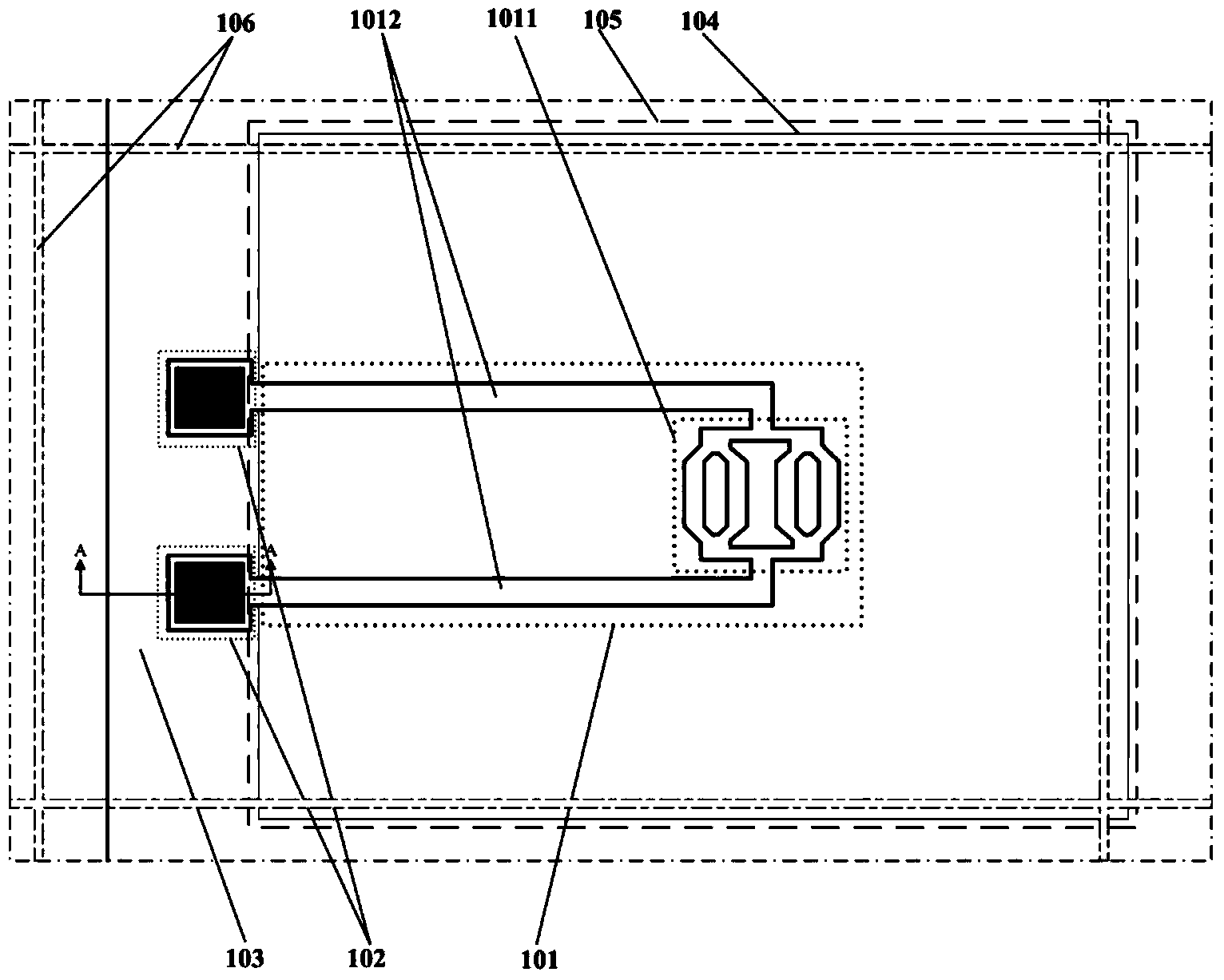

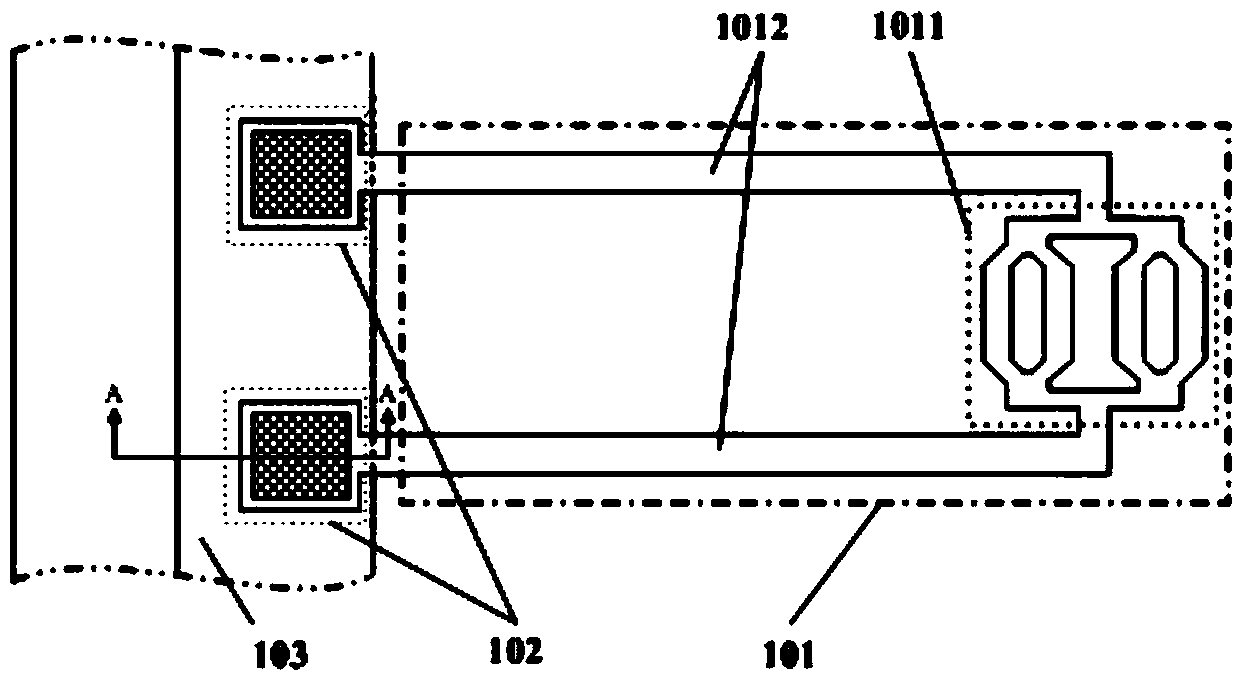

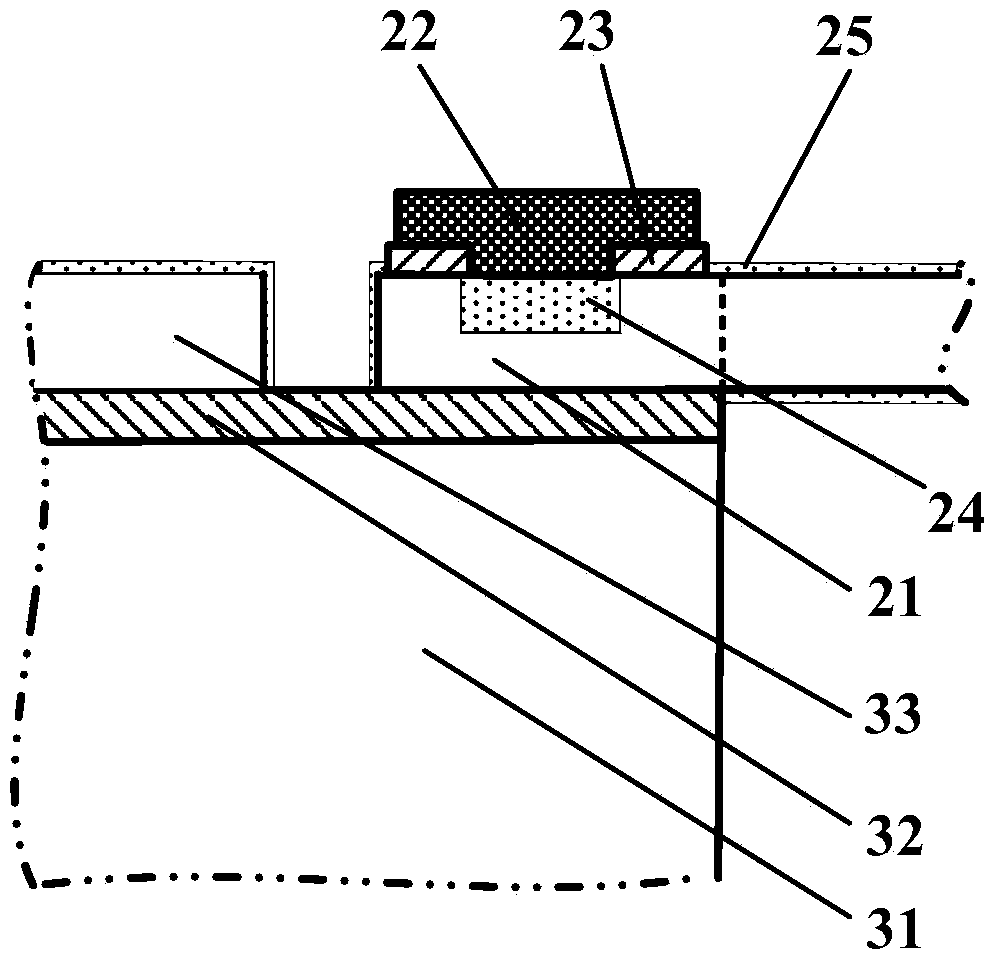

[0067] Example: in figure 1 , figure 2 , image 3 Among them, the all-silicon MEMS methane sensor includes a silicon element 101, a fixed end 102 and a silicon frame support 103; the silicon frame support 103 is an SOI substrate, including a silicon substrate 31, a buried A layer of silicon oxide 32 and a top layer of silicon 33 on the buried layer of silicon oxide 32, the top layer of silicon 33 is single crystal silicon;

[0068] The fixed end 102 is on the buried layer silicon oxide 32 on the silicon frame support 103; the fixed end 102 includes the silicon layer 21, the silicon oxide layer 23 outside the silicon layer 21 and the metal Pad 22 used as an electrical lead-out pad The silicon layer 21 of the fixed end 102 is arranged on the buried layer of silicon oxide 12; the supporting silicon layer 21 of the fixed end 102 is provided with a doped silicon layer 24; the metal Pad 22 of the electric lead pad is arranged on the silicon On the silicon oxide layer 23 above th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com