Simulated ship waste gas system for wet washing

A technology of wet scrubbing and exhaust gas system, which is applied in the field of simulating ship exhaust system, can solve the problems of many environmental factors, poor repeatability of the experimental process, and complex exhaust gas components, so as to reduce the interference of impurity components, reduce the cost of testing and inspection, and shorten the evaluation cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with drawings and embodiments.

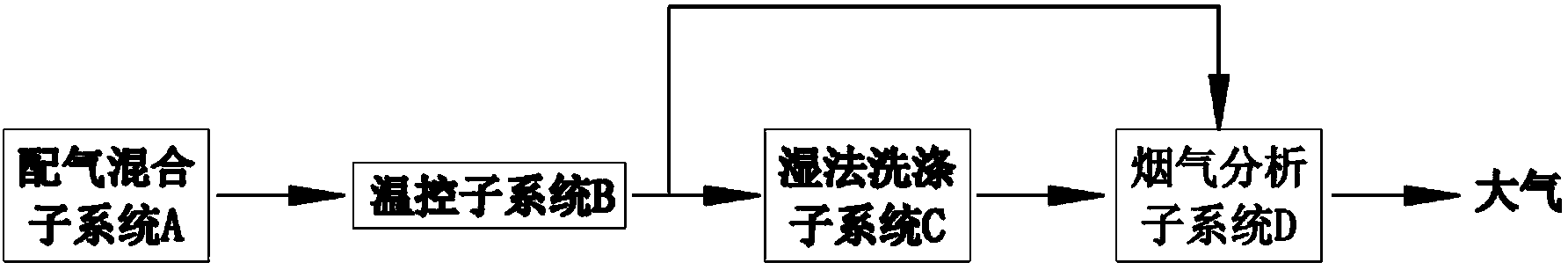

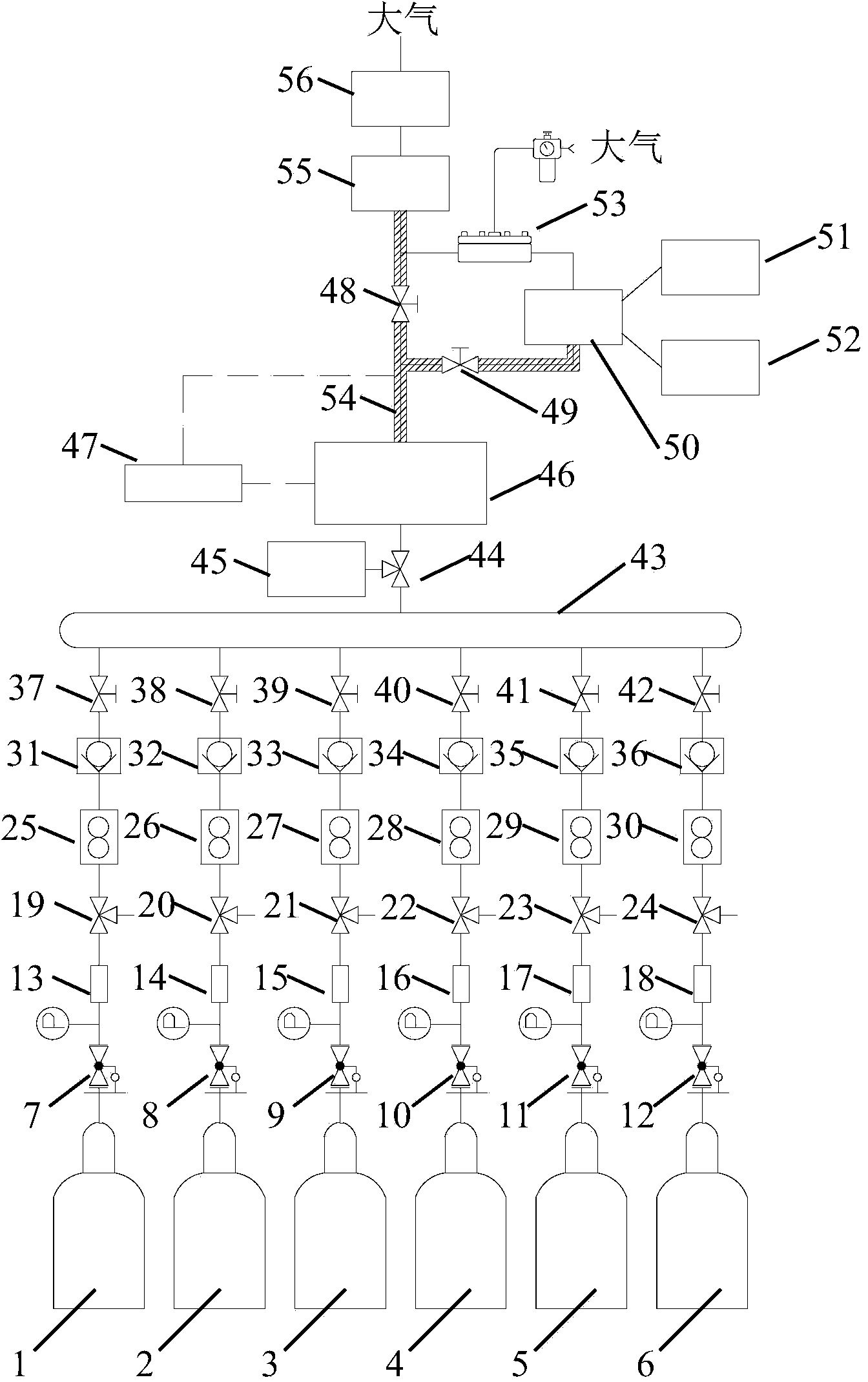

[0033] Such as figure 1The simulated ship exhaust gas system for wet scrubbing shown includes: gas distribution and mixing subsystem A for mixing mixed gas to simulate the exhaust gas under actual ship working conditions of the ship power plant; used to study the effect of exhaust gas temperature on wet scrubbing The temperature control subsystem B that affects the effect of the law; the wet scrubbing subsystem C that reacts the simulated ship exhaust gas at a certain temperature with the washing medium solution; the smoke that quantitatively measures the gas composition and concentration changes of each component in the simulated ship exhaust gas Gas analysis subsystem D. Among them, the output end of the gas distribution and mixing subsystem A is directly connected to the temperature control subsystem B, and after heating and heat preservation treatment, the ship exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com