Method for improving diffusion uniformity of crystalline silicon solar cell

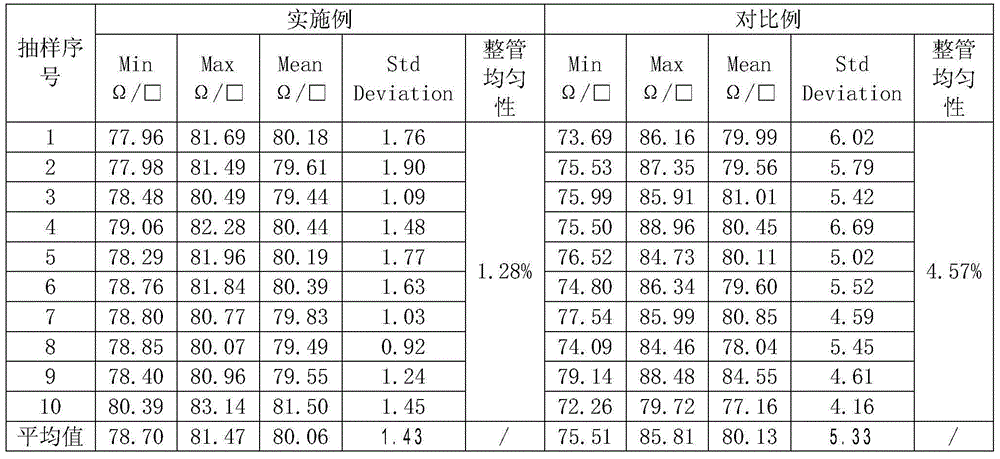

A solar cell and uniformity technology, which is applied in the field of solar photovoltaics, can solve problems such as poor uniformity and compactness, and affect the uniformity of square resistance, and achieve the goal of improving the uniformity of phosphorus diffusion, good uniformity and compactness, and improving conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] A method for improving the diffusion uniformity of a crystalline silicon solar cell, comprising the steps of:

[0030] 1) A P-type polysilicon wafer with a size of 156mm×156mm is subjected to conventional texturing.

[0031] 2) place the silicon chip after the texturing in the ozone atmosphere that photochemical ozone generator produces, make the texturing surface of silicon chip oxidize in ozone, the oxygen flow rate of photochemical ozone generator is 2-40L / min,, The purging time is 0.2-60min.

[0032] 3) Diffusion of silicon wafers oxidized in ozone, followed by conventional coating, front and back electrode printing, and sintering.

[0033] The diffusion step adopts the following diffusion process, and the diffusion equipment adopts the Dutch TEMPRESS diffusion furnace:

[0034] 1. Preparation stage: Big N 2 Flow 5slm, pressure 5pa

[0035] 2. Entering the boat stage: Big N 2 Flow 5slm, O 2 Flow 0sccm, small N 2 Flow 0sccm, pressure 5Pa;

[0036] 3. Out of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com