Catalyst for conversion of fructose to 5-hydroxymethylfurfural

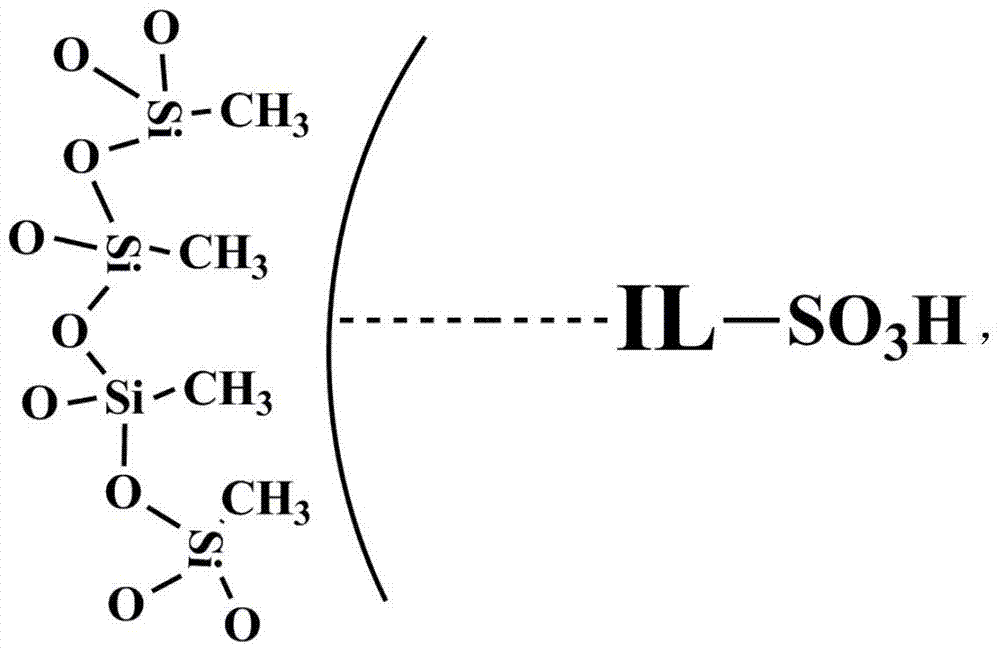

A technology of hydroxymethyl furfural and a catalyst is applied in the field of converting fructose into 5-hydroxymethyl furfural, and can solve the problems of difficult recovery of catalyst phosphotungstic acid, unfriendly environment, high viscosity of ionic liquid, etc., and achieves a simple and practical loading method, Clarify economic and social benefits, the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

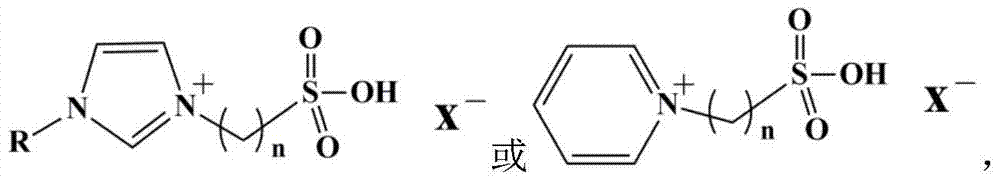

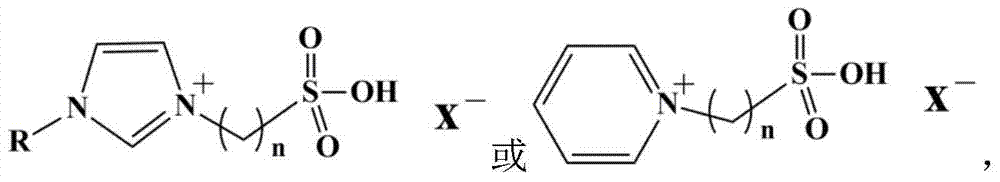

Embodiment 1

[0025] In a 250mL round bottom flask, take 1mL of an aqueous solution of 0.05mol / L ionic liquid 1-(3-sulfonic acid)-propyl-3-methylimidazolium bisulfate, then add 50mL of liquid paraffin, ultrasonicate for 5min, and then Stand still for 5 minutes and repeat 5 times. Then add 50 mL of 0.3 mol / L methyltrichlorosilane in isooctane solution, stir at room temperature, and feed water vapor (0.1 L / min) at the same time, and react for 5 h. After suction filtration, the obtained solid was dried at 60°C for 24 hours to obtain a catalyst.

Embodiment 2

[0027] In a 250mL round bottom flask, take 1mL of an aqueous solution of 0.04mol / L ionic liquid 1-(3-sulfonic acid)-butyl-3-methylimidazolium bisulfate, then add 50mL of liquid paraffin, ultrasonicate for 5min, and then Stand still for 5 minutes and repeat 5 times. Then add 50 mL of 0.25 mol / L methyltrichlorosilane in isooctane solution, stir at room temperature, and feed water vapor (0.1 L / min) at the same time, and react for 5 h. After suction filtration, the obtained solid was dried at 60°C for 24 hours to obtain a catalyst.

Embodiment 3

[0029] In a 250mL round bottom flask, take 1mL of an aqueous solution of 0.08mol / L ionic liquid 1-(3-sulfonic acid)-propyl-3-methylimidazolium hydrogensulfate, then add 50mL of liquid paraffin, ultrasonicate for 5min, and then Stand still for 5 minutes and repeat 5 times. Then add 50 mL of 0.2 mol / L methyltrichlorosilane in isooctane solution, stir at room temperature, and feed water vapor (0.1 L / min) at the same time, and react for more than 5 hours. After suction filtration, the obtained solid was dried at 60°C for 24 hours to obtain a catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com