Full-automatic vanadium-nitrogen alloy discharging device

A technology of unloading device and vanadium-nitrogen alloy, which is applied in the directions of packaging, loading/unloading, transportation and packaging, etc. It can solve the problems that cannot satisfy large-scale industrial production, workers are easy to absorb dust, and the impact on human health, so as to reduce dust damage , the base quality is large, and the effect of good cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

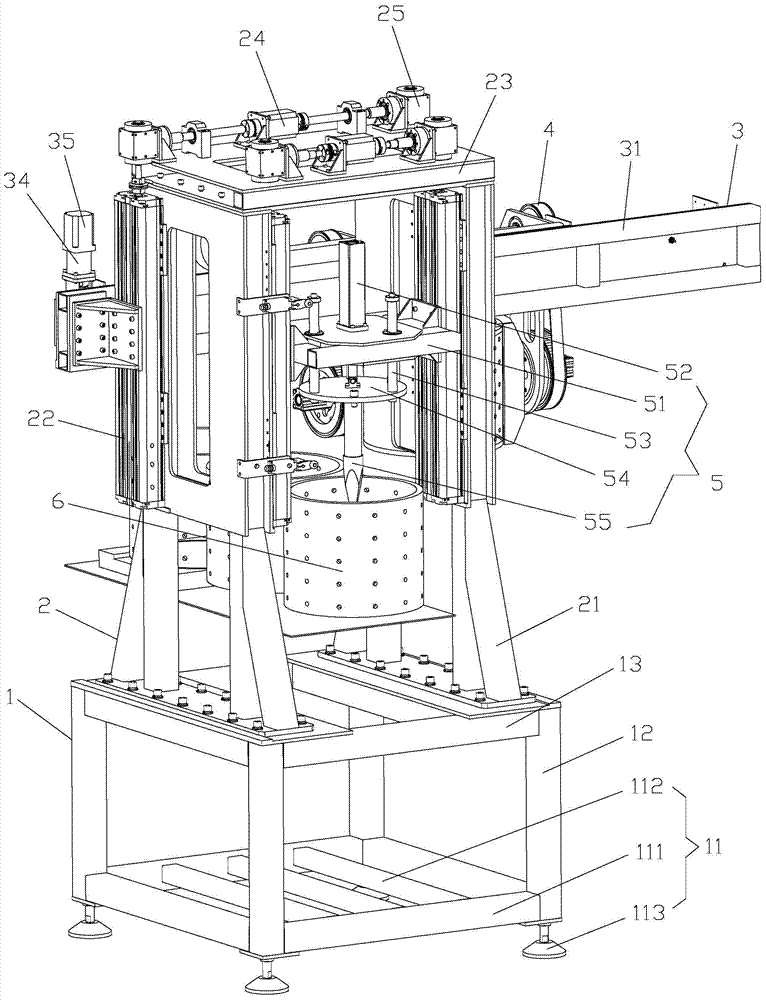

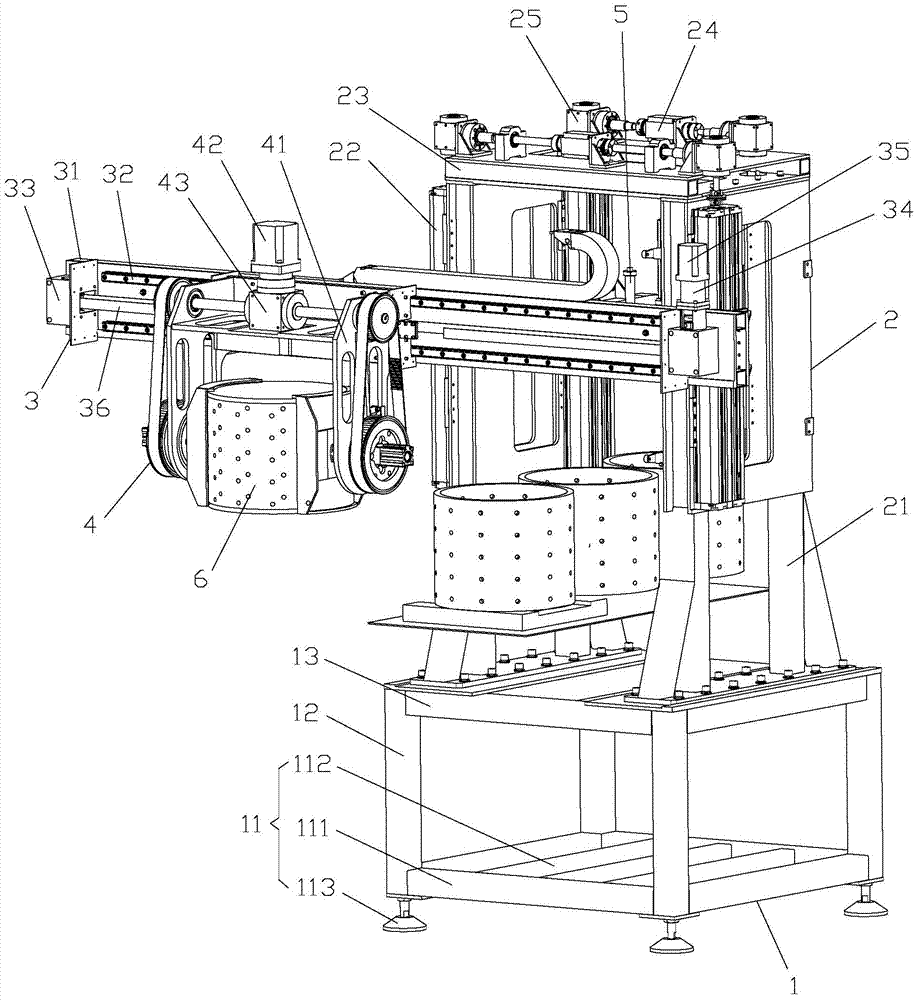

[0030] Such as Figures 1 to 13As shown, the vanadium-nitrogen alloy automatic unloading device of the present invention includes a base 1, a Z-axis moving mechanism 2, a Y-axis moving mechanism 3, a turning mechanism 4, a breaking mechanism 5 and an electric control system.

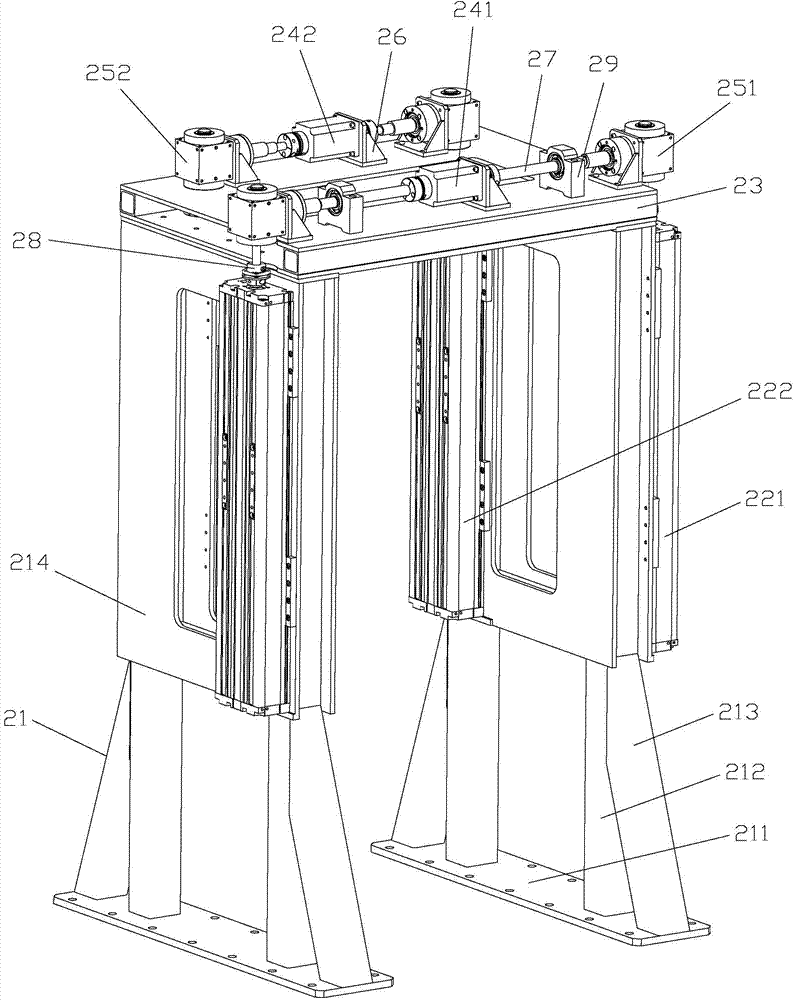

[0031] The base 1 is a rectangular parallelepiped frame structure, which includes a bottom frame 11 , a column 12 and a top frame 13 . The underframe 11 is a rectangular frame structure, which is assembled by connecting four bottom beams 111 end to end. The connecting beams 112 are parallel to each other and to another pair of oppositely arranged bottom beams 111 ; wherein, the four corners of the bottom of the bottom frame 11 are symmetrically fixed with four adjustable feet 113 . The uprights 12 are fixed vertically between the bottom frame 11 and the top frame 13, wherein the uprights 12 are four symmetrically fixed on the four corners of the top of the bottom frame 11, and the four uprights 12 are e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com