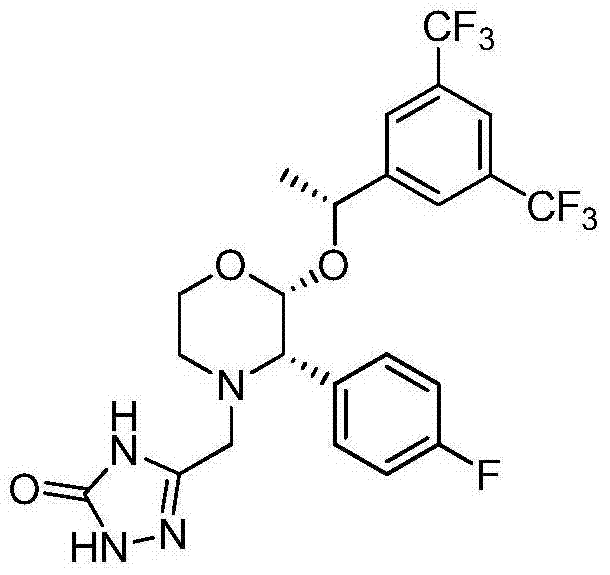

Refining method of aprepitant key intermediate

A refining method and a key technology, applied in the refining of neurokinin-1 receptor antagonist aprepitant intermediates, the refining of pharmaceutical intermediates, can solve the problem of increased side reactions, decreased compound stability, and difficult to remove and other problems, to achieve the effect of reducing the formation of defluorination impurities, reducing side reactions and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

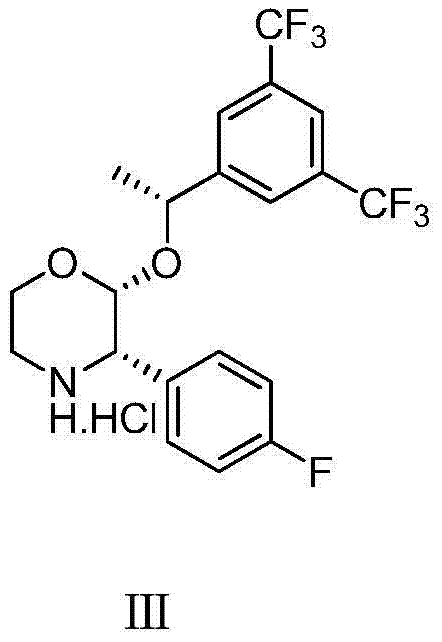

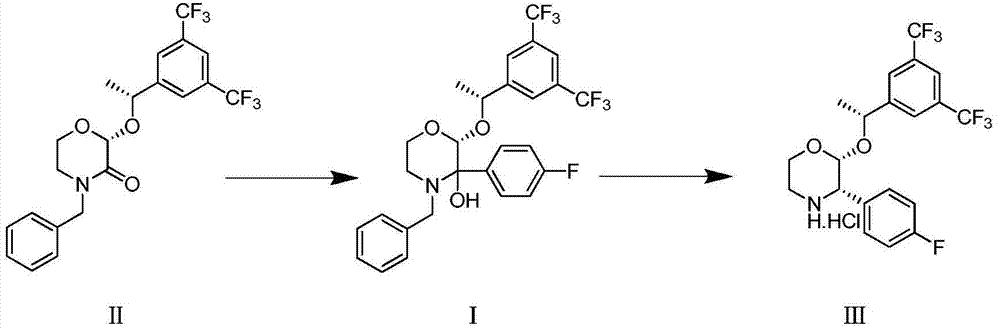

[0034] Preparation of intermediate (I):

[0035] 1.40kg compound (II) dissolved in 0.8L tetrahydrofuran and 4.0L 4-fluorophenylmagnesium bromide tetrahydrofuran solution (1.0M) were subjected to Grignard addition reaction to generate intermediate (I) reaction solution, poured into the stirred In the mixed solution of 10L methyl tert-butyl ether and 10L saturated aqueous ammonium chloride solution, the temperature did not rise significantly. After stirring for 10 minutes, let it stand for stratification, separate the organic phase, and wash it with 6L water and 6L saturated saline successively. Then it was concentrated to dryness under reduced pressure at 25°C to obtain 1.55 kg of white solid. Yield 91.0%. HPLC purity: 99.1%.

Embodiment 2

[0037] Preparation of intermediate (I):

[0038] 1.40kg compound (II) dissolved in 0.8L tetrahydrofuran and 4.0L 4-fluorophenylmagnesium bromide tetrahydrofuran solution (1.0M) were subjected to Grignard addition reaction to generate intermediate (I) reaction solution, poured into the stirred In the mixed solution of 20L methyl tert-butyl ether and 15L saturated aqueous ammonium chloride solution, the temperature did not rise significantly. After stirring for 10 minutes, let it stand for stratification, separate the organic phase, and wash it with 10L water and 10L saturated brine successively. Then it was concentrated to dryness under reduced pressure at 25°C to obtain 1.59kg of white solid. Yield 93.5%. HPLC purity: 98.8%.

Embodiment 3

[0040] Preparation of intermediate (I):

[0041]1.40kg compound (II) dissolved in 0.8L tetrahydrofuran and 4.0L 4-fluorophenylmagnesium bromide tetrahydrofuran solution (1.0M) were subjected to Grignard addition reaction to generate intermediate (I) reaction solution, poured into the stirred In the mixed solution of 10L methyl tert-butyl ether and 10L saturated aqueous ammonium chloride solution, the temperature did not rise significantly. After stirring for 10 minutes, let it stand for stratification, separate the organic phase, and wash it with 6L water and 6L saturated saline successively. Then it was concentrated to dryness under reduced pressure at 20°C to obtain 1.56 kg of white solid. Yield 91.7%. HPLC purity: 98.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com