Information security risk assessment method oriented to typical metallurgy process control system

A technology of control system and process control, which is applied in general control system, control/adjustment system, test/monitoring control system, etc., and can solve the problems of large control system network topology, complex information security management, long process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

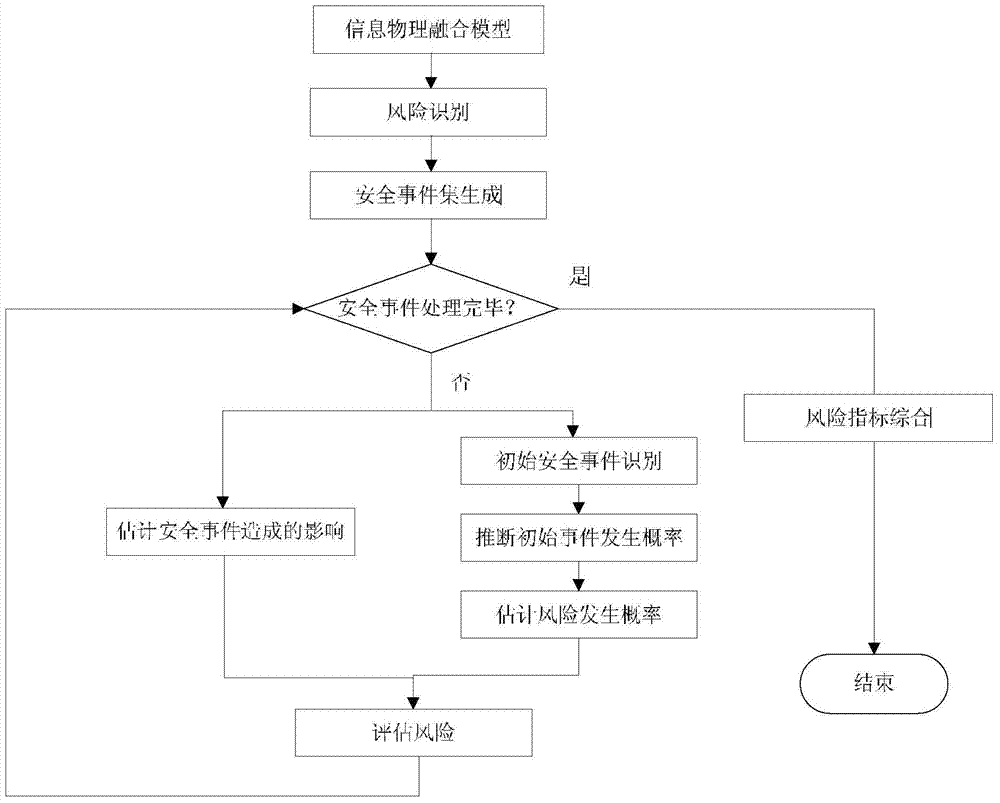

[0044] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Such as figure 1 shown, including the following steps:

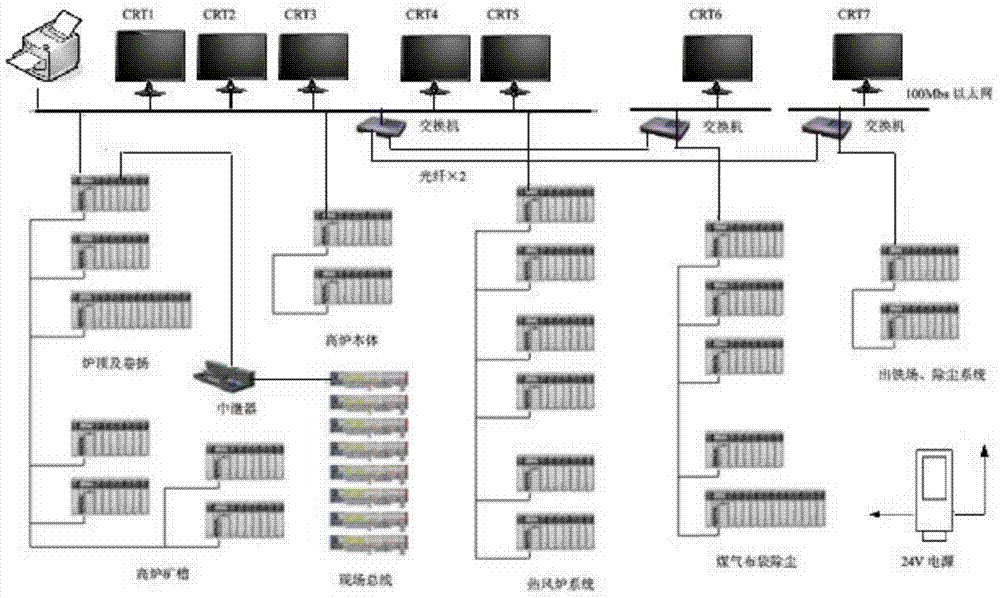

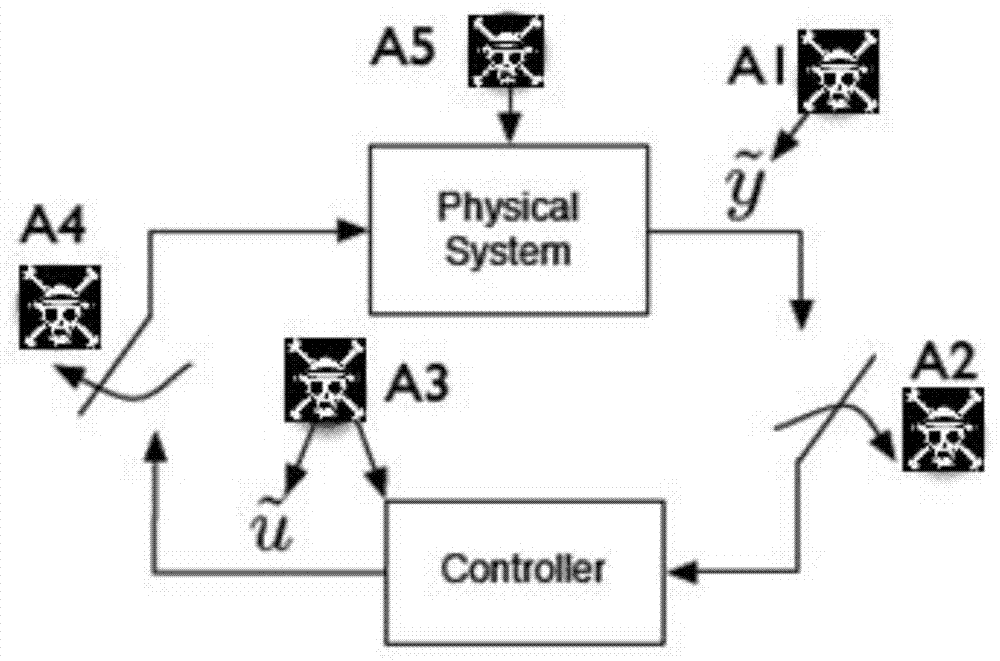

[0045] (1) For the typical metallurgical process flow control system, the mathematical modeling of the control system based on cyber-physical fusion is carried out. Model method, in which the continuous dynamic model related to the metallurgical process flow is represented by a set of traditional linear or nonlinear differential equations / equations of state, and is realized with the Matlab Simulink toolbox; discrete events are represented by the Petri Net (PN) model, And use a Simulink toolbox PNL to implement, the PN discrete model can be integrated into the Simulink block diagram, and the synchronization state transfer of the petri Net model mainly depends on the triggering of external events. At the same time, the Petri Net model is extended to model the communication network component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com