A kind of power cable with drying layer

A technology of power cable and drying layer, applied in the field of power cable with drying layer, can solve the problems of easily damaged cable core, no drying layer, high interference humidity, etc., and achieves stable performance, which is not easy to fall off, prevents the intrusion of water vapor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

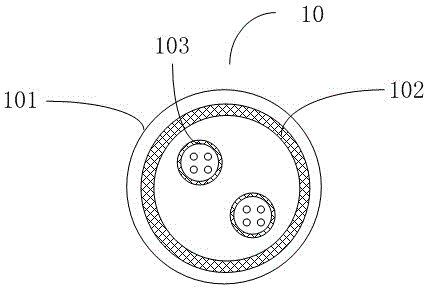

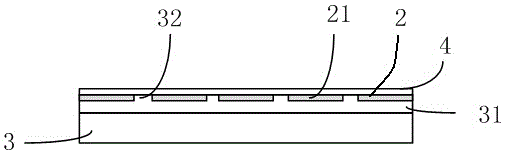

[0020] Such as figure 1 As shown, a power cable with a dry layer, the power cable 10 includes a cable shell 101 and a cable core 103, the power cable 10 also includes a dry layer structure 102, the dry layer structure 102 is arranged on the inner surface of the cable shell 101, as figure 2 , 3 As shown, wherein the dry layer structure 102 includes a flexible substrate 3, a polymer layer 31 and a dry layer 21, the dry layer 21 is embedded on the side of the surface of the polymer layer 31 away from the flexible substrate 3, the dry layer 21 is formed by the arrangement of drying blocks 2 arrays, and the drying blocks 2 are composed of desiccant; the distance between the adjacent drying blocks 2 is 150 μm to 300 μm, and the adjacent drying blocks 21 are mutually Independence; the present invention provides a power cable with a dry layer. The structure adopts a dry layer between the cable core and the cable sheath, which can well prevent the intrusion of water vapor and protect...

Embodiment 2

[0024] Such as figure 2 , 3 As shown, wherein the dry layer structure 102 includes a flexible substrate 3, a polymer layer 31 and a dry layer 21, the dry layer 21 is embedded on the side of the surface of the polymer layer 31 away from the flexible substrate 3, the dry layer 21 is formed by the arrangement of drying blocks 2 arrays, and the drying blocks 2 are made of desiccant; the desiccant is composed of bentonite, attapulgite, silica gel, calcium chloride, magnesium sulfate, calcium sulfate, silicon dioxide and poly Acrylamide composition.

[0025] Among them, take two containers respectively, take bentonite: 50 parts, 55 parts, attapulgite: 20 parts, 27 parts, silica gel: 22 parts, 25 parts, calcium chloride: 15 parts, 20 parts, respectively put into two In the container, put magnesium sulfate: 8 parts, calcium sulfate: 12 parts, silicon dioxide: 18 parts, polyacrylamide: 3 parts, put them into two containers respectively, and then configure them into ink, using silk s...

Embodiment 3

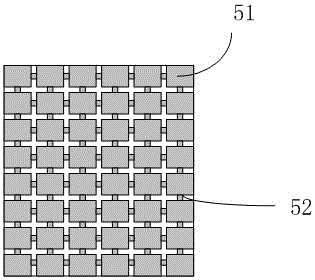

[0027] In another preferred solution, the drying layer structure 102 can also be a continuous structure, the drying layer structure 102 includes drying pieces 51 and connecting pieces 52, the drying pieces 51 are arranged in an array, and the adjacent drying pieces 51 Connect by connecting piece 52, form an integral dry layer; Wherein, be filled with mixed material in the dry piece 51; Said mixed material is made of aluminum, nickel, chromium, bentonite, attapulgite, silica gel, calcium chloride, magnesium sulfate, Calcium sulfate, silicon dioxide and polyacrylamide.

[0028] Among them, aluminum: 30 parts, nickel: 10 parts, chromium: 10 parts, bentonite: 60 parts, attapulgite: 35 parts, silica gel: 25 parts, calcium chloride: 20 parts, magnesium sulfate: 8 parts, sulfuric acid Calcium: 12 parts, silicon dioxide: 18 parts, polyacrylamide: 3 parts; put it into a container, then configure it into ink, and use screen printing to form the mixed material on the substrate; In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com