Processing method for manmade shaving board

A processing method and particleboard technology, applied in the direction of manufacturing tools, wood processing appliances, and pretreatment of molding materials, can solve the problems of increasing the amount of adhesive used, poor flame retardant effect of the board surface, and affecting the uniformity of flame retardants, etc., to achieve Improve the overall flame retardant performance, simple composition, and improve the effect of smoke suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

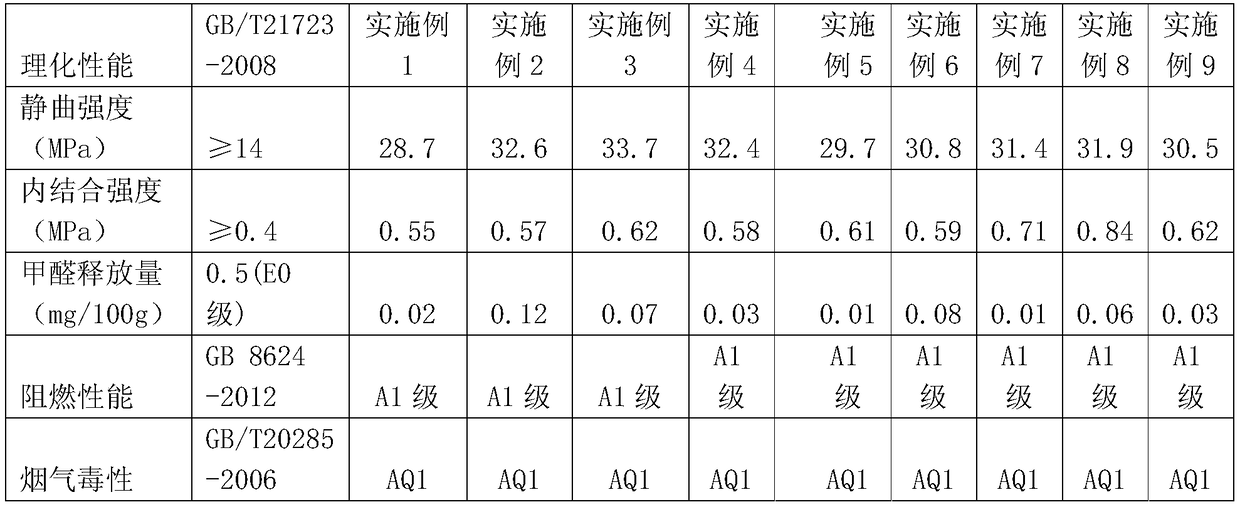

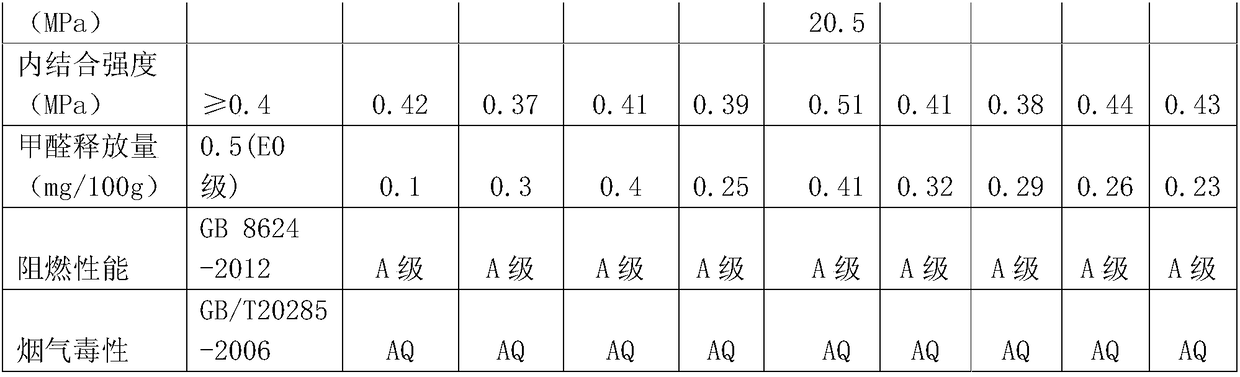

Examples

Embodiment 1

[0021] A processing method for artificial particleboard, comprising the following steps:

[0022] 1) Adhesives, flame retardants and shavings are fully mixed according to the mass ratio of 0.20:0.2:100, and paved into a slab of multi-layer structure particleboard;

[0023] 2) Send the slab directly into the hot press for hot pressing, the hot pressing temperature is 90 degrees Celsius, and the hot pressing pressure is 14kg / cm 2 ;

[0024] 3) Neatly stack the hot-pressed plates after step 2) and cool them down to normal temperature for edge sawing and polishing to obtain rough plates;

[0025] 4) Take a certain amount of flame retardant, and mix it according to the weight ratio of flame retardant: adhesive = 0.7:1.5 to obtain a flame retardant, and then uniformly coat the surface of the rough plate obtained in step 3) with the flame retardant , dry naturally to get the finished product.

[0026] In step 4), the flame retardant is made of the following raw materials in parts ...

Embodiment 2

[0030] The processing method of the artificial particle board is the same as that of Example 1, the difference is that the composition of the flame retardant: in parts by weight, is made of the following raw materials: 80 parts of magnesium hydroxide, 60 parts of aluminum hydroxide, 25 parts of ultra-fine zinc borate, 20 parts of nano-Mg / Al-LDH, 18 parts of talcum powder, and 10 parts of modifier. Wherein, the surfaces of the magnesium hydroxide and the aluminum hydroxide are coated with a silane coupling agent, and the modifier may be nano silicon dioxide.

[0031] In this embodiment, both the magnesium hydroxide and the aluminum hydroxide are powders.

[0032] The preparation method of the flame retardant is the same as that of Example 1.

Embodiment 3

[0034] A processing method for artificial particleboard, comprising the following steps:

[0035] 1) Adhesives, flame retardants and shavings are fully mixed according to the mass ratio of 0.35:0.1:100, and paved into a slab of multi-layer structure particleboard;

[0036] 2) Send the slab directly into the hot press for hot pressing, the hot pressing temperature is 100 degrees Celsius, and the hot pressing pressure is 10kg / cm 2 ;

[0037] 3) Neatly stack the hot-pressed plates after step 2) and cool them down to normal temperature for edge sawing and polishing to obtain rough plates;

[0038] 4) Take a certain amount of flame retardant, and mix it according to the weight ratio of flame retardant: adhesive = 0.4:1 to obtain a flame retardant, and then uniformly coat the surface of the rough plate obtained in step 3) with the flame retardant , dry naturally to get the finished product.

[0039] In step 4), the flame retardant is made of the following raw materials in parts b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com