Metal ceramic X ray tube filled with water cooling anode device

A cermet and water-cooled anode technology, applied in the field of X-ray tubes, can solve the problems of X-ray tube damage, insufficient heat dissipation of the air-cooled anode structure, etc., and achieve the effects of increased working time, expanded anode dissipation power, and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings.

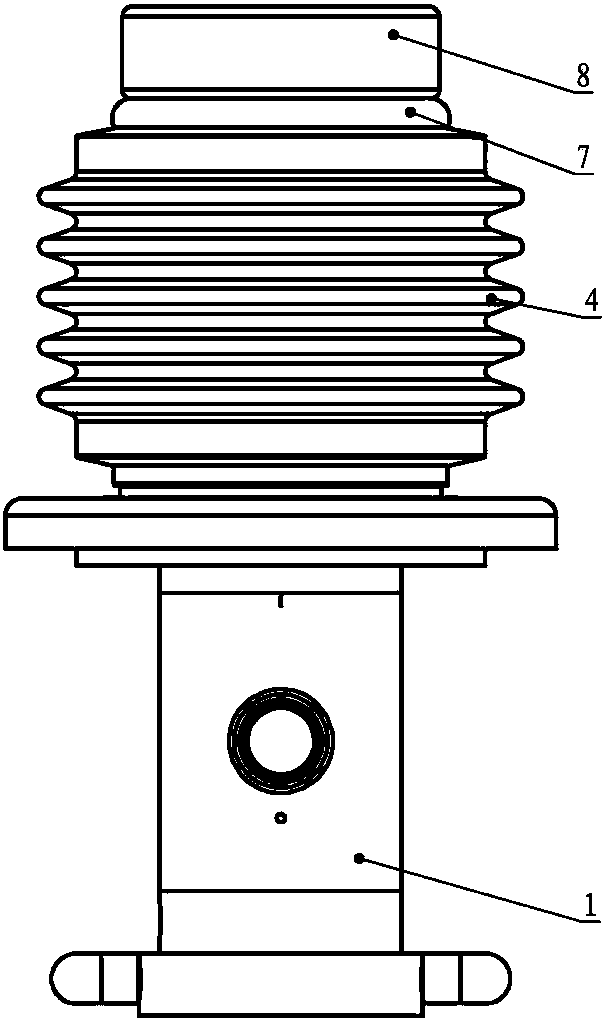

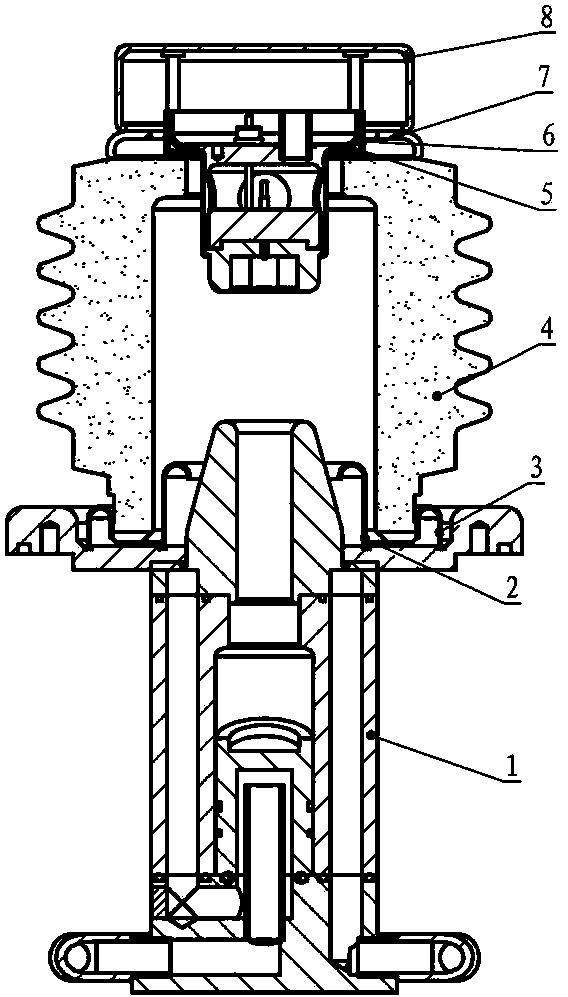

[0019] A metal-ceramic X-ray tube equipped with a water-cooled anode device, such as figure 1 and figure 2 As shown, it includes a metal-ceramic tube shell and a cathode focusing device, and a water-cooled anode device 1 is installed in the metal-ceramic X-ray tube. The top is provided with a connecting ring 6, the cathode focusing device 5 is connected with the connecting ring 6 by argon arc welding, the positioning ring 7 is sealed with the metal ceramic tube shell 4, the tail cover 8 is connected with the positioning ring 9 by screws, and the anode cover 2 is connected with the water-cooled anode device. 1 Sealed connection.

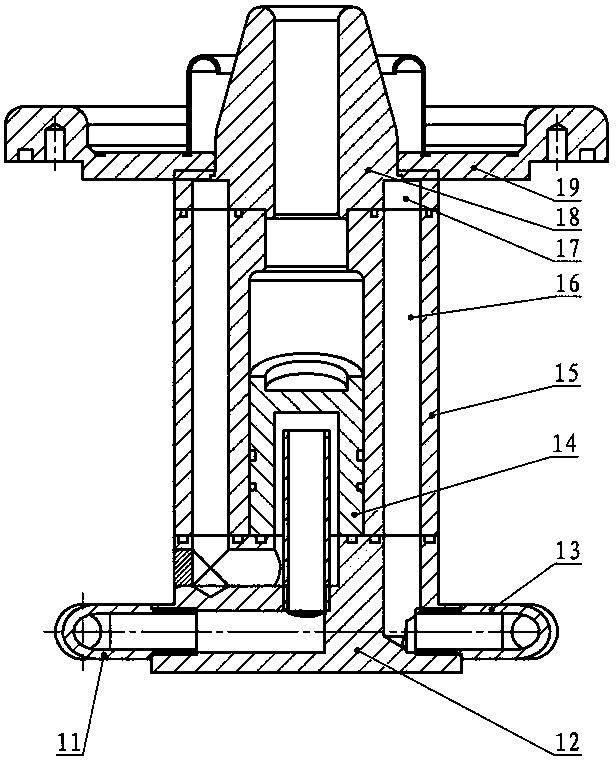

[0020] image 3 is the structural schematic diagram of the water-cooled anode device in the present invention, Figure 4 It is a schematic diagram of the structure of the cooler in the water-cooled anode device. The water-cooled anode d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com