Instant soybean flour, soybean milk and preparation method thereof

A technology of soybean milk and soybean powder, which is applied in the direction of dairy products, milk substitutes, applications, etc., can solve the problems of unfavorable continuous production, long reaction time, and reduced product yield, so as to reduce the difficulty of process concentration and granulation, and enzymatic hydrolysis Effect of short time and improvement of instant solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

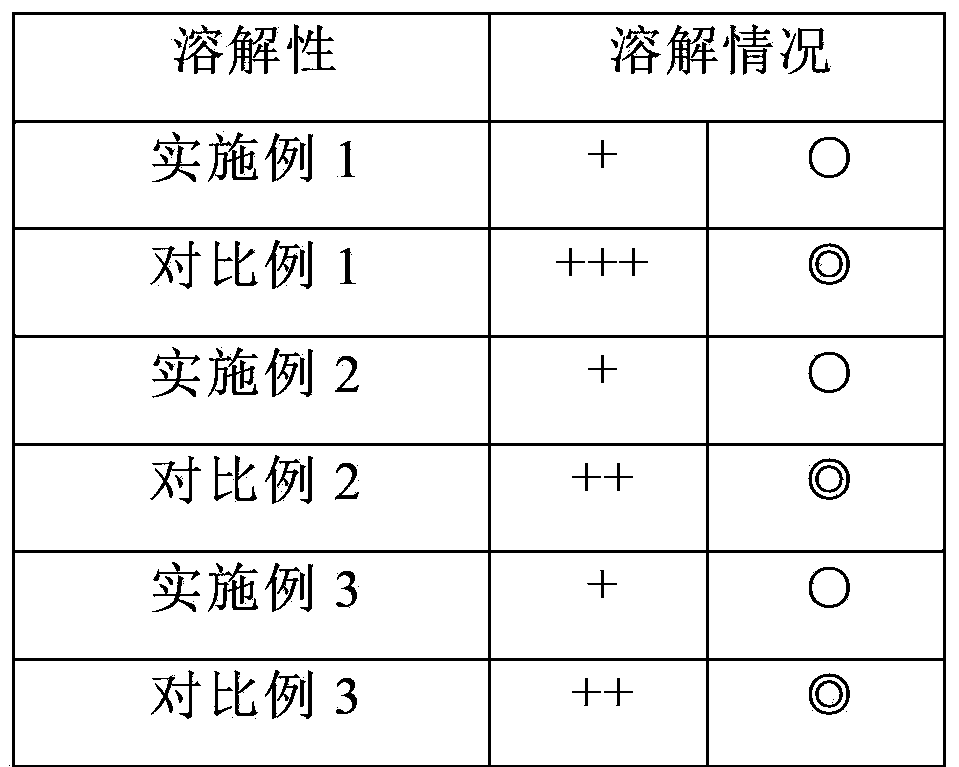

Examples

preparation example Construction

[0054] The preparation method of bean flour comprises the following steps:

[0055] 1) Add protease to the soy milk base material, and enzymatically hydrolyze for 5-10 minutes;

[0056] 2) Add fresh soymilk base material to the soy milk base material after enzymolysis, and enzymolyze it for 5-10 minutes;

[0057] 3) Repeat step 2) one or more times to obtain an enzymatic hydrolysis solution with more than three enzymatic hydrolysis times;

[0058] 4) drying the enzymolysis solution obtained in step 3) to obtain soybean powder.

[0059] In a specific embodiment of the present invention, the preparation method of bean flour comprises the following steps:

[0060] 1) Add protease to the soy milk base material, and enzymatically hydrolyze for 5-10 minutes;

[0061] 2) Add fresh soymilk base material to the soy milk base material after enzymolysis, and enzymolyze it for 5-10 minutes;

[0062] 3) Add fresh soymilk base to the enzymatically hydrolyzed soymilk base obtained in ste...

Embodiment 1

[0163] Get 1000g of soybeans, grind the pulp, filter and remove the bean dregs, and obtain 8000g of soybean milk base material.

[0164] Take 500g of soybean milk base material and stir at 45°C, preheat for 10 minutes, measure the pH to 6.47 (44.6°C), add papain 0.015% (w / w), and react for 5 minutes to obtain reaction solution 1;

[0165] Take 500g of soybean milk base material preheated to 45°C and mix it with the reaction solution 1, continue to react at 45°C for 5 minutes to obtain the reaction solution 2, and the measured pH is 6.37 (46.4°C);

[0166] Take 500g of soybean milk base material preheated to 45°C and mix it with the reaction solution 2, continue to react at 45°C for 5 minutes to obtain the reaction solution 3, and the measured pH is 6.33 (45.9°C);

[0167] Take 500g of soybean milk base material preheated to 45°C and mix it with the reaction solution 3, continue to react at 45°C for 5 minutes to obtain the reaction solution 4, the measured pH is 6.36 (45.3°C); ...

Embodiment 2

[0178] Get 1000g of soybeans, grind the pulp, and filter out the bean dregs to obtain 8000g of soybean milk base material;

[0179] Take 500g of soybean milk base material, stir and preheat at 50°C for 10 minutes, the measured pH is 6.47 (44.0°C), add neutral protease 0.05% (w / w), and react for 5 minutes to obtain reaction solution 1, and the measured pH is 6.38 (43.3°C );

[0180] Take 500g of the original slurry which has been preheated to 50°C and mix it with the reaction solution 1, continue to react at 50°C for 5 minutes to obtain the reaction solution 2, and the measured pH is 6.41 (42.5°C);

[0181] Take 500g of the original slurry which has been preheated to 50°C and mix it with the reaction solution 2, continue to react at 50°C for 5 minutes to obtain the reaction solution 3, and the measured pH is 6.43 (44.0°C);

[0182] Take 500g of the original slurry which has been preheated to 50°C and mix it with the reaction solution 3, and continue to react at 50°C for 5 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com