Welding apparatus comprising a welding assistance

A technology of welding equipment and auxiliary systems, applied in welding equipment, arc welding equipment, welding accessories, etc., to achieve the effect of reducing changes or quality differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

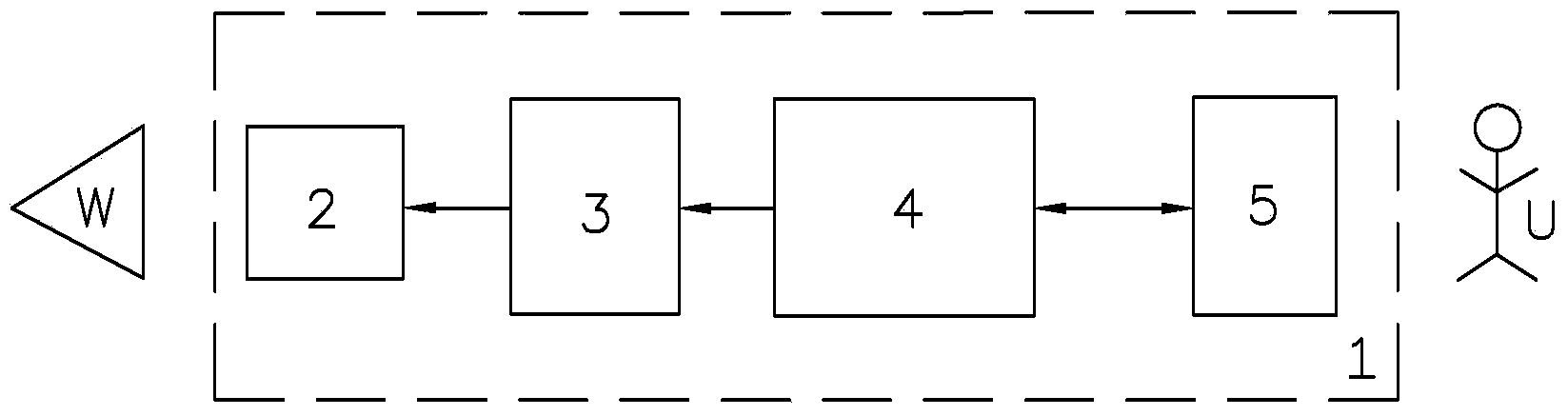

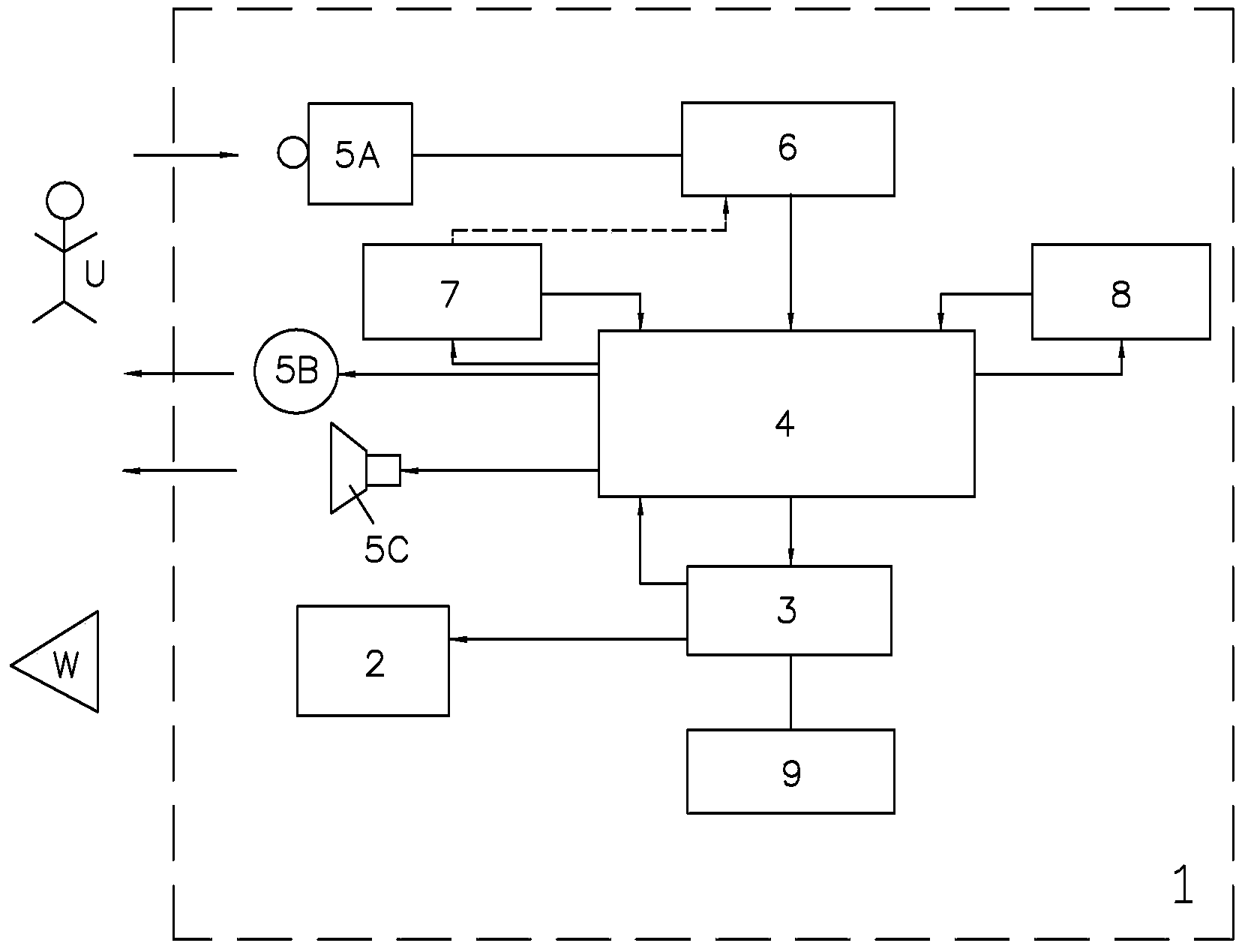

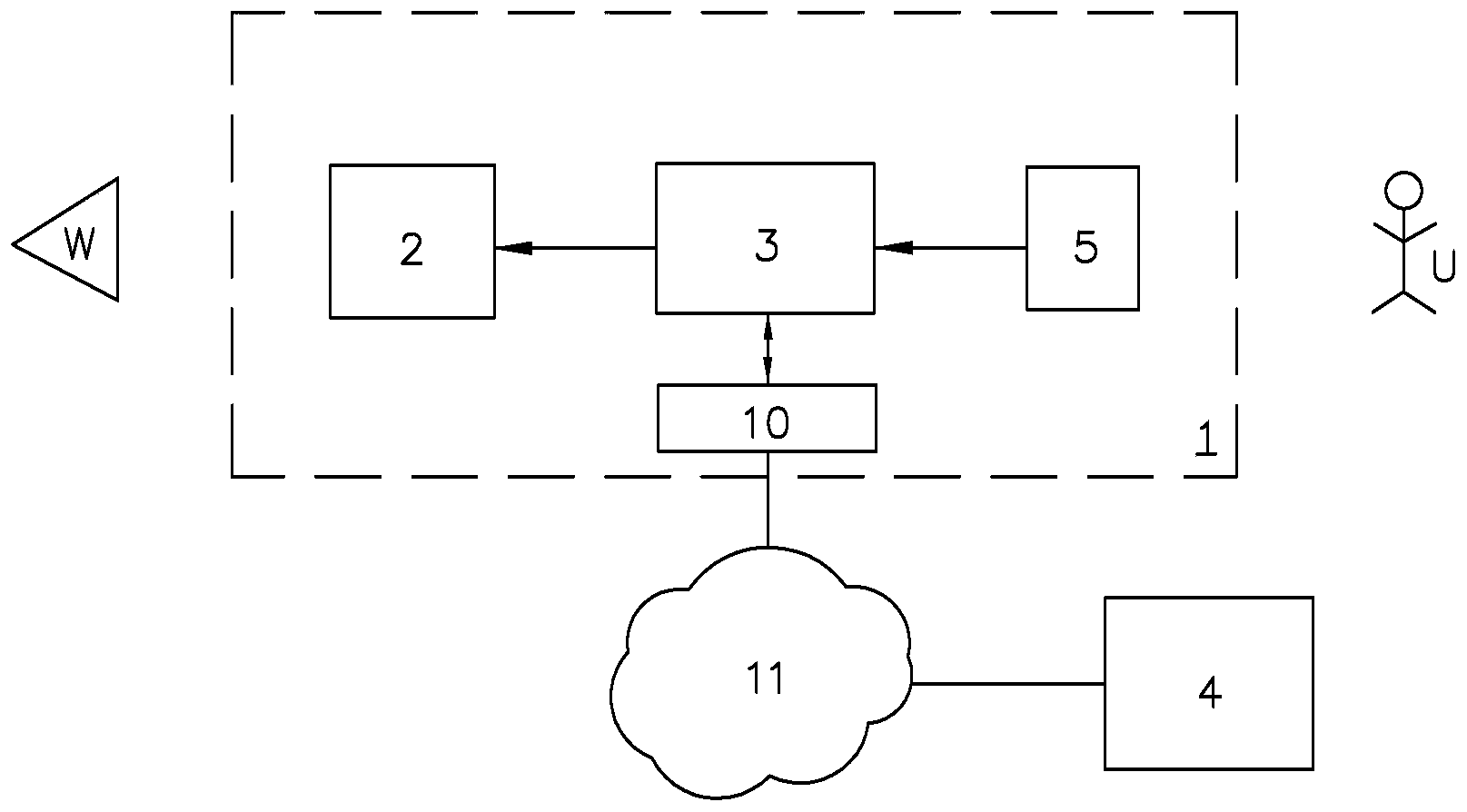

[0035] as by figure 1 It can be seen that the welding device 1 according to the illustrated embodiment has a plurality of units. The workpiece W to be welded by the welding device 1 is figure 1is symbolically represented by a triangle in . The welding device 1 has a welding unit 2 for welding a workpiece W. As shown in FIG. The welding apparatus 1 is operated by a welder or user U who welds a workpiece W during the welding process. The welding unit 2 can be, for example, a welding torch. In a possible embodiment, the welding torch can be connected to the welding control unit 3 of the welding device 1 by means of a mechanical coupling element and a hose assembly. The welding control parameter SSP of the welding unit 2 can be adjusted by means of the welding control unit 3 so that welding can be performed with a welding torch. The welding control parameter SSP is, for example, at least one welding power and / or electrode feed rate and / or arc length and / or shielding gas type ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com