Movable carbonization furnace for nearby carbonization and field returning of stalk and carbon method preparation thereof

A straw carbonization and carbonization furnace technology, which is applied in coking ovens, special forms of dry distillation, petroleum industry, etc., can solve problems such as troublesome operation, high transportation costs of raw materials and finished products, short circuit of flue gas in the furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] 1. Preparation

[0036] Cut the straw with a water content of about 20% into short sections of about 50mm for later use;

[0037] 2. Furnace, ignition

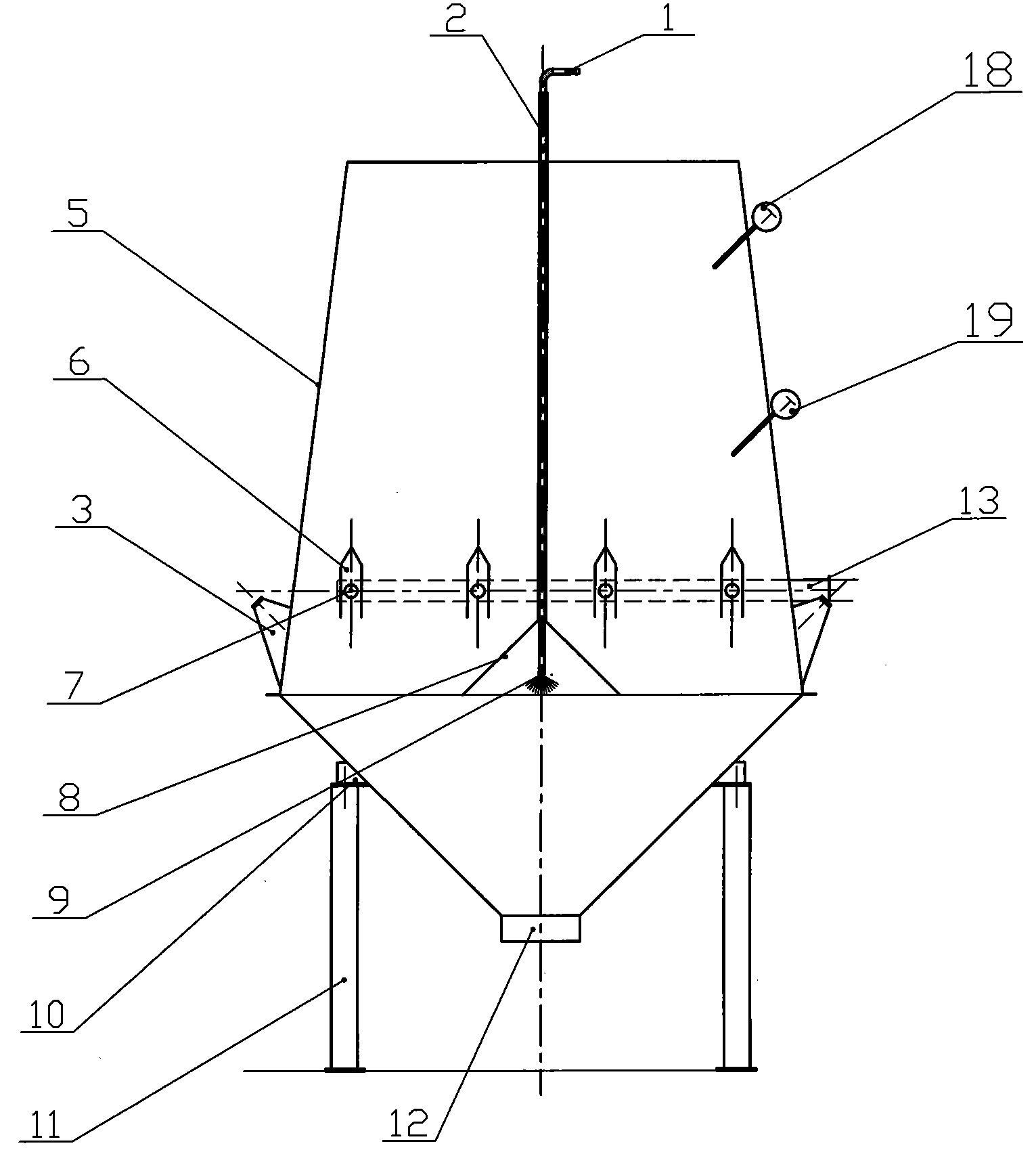

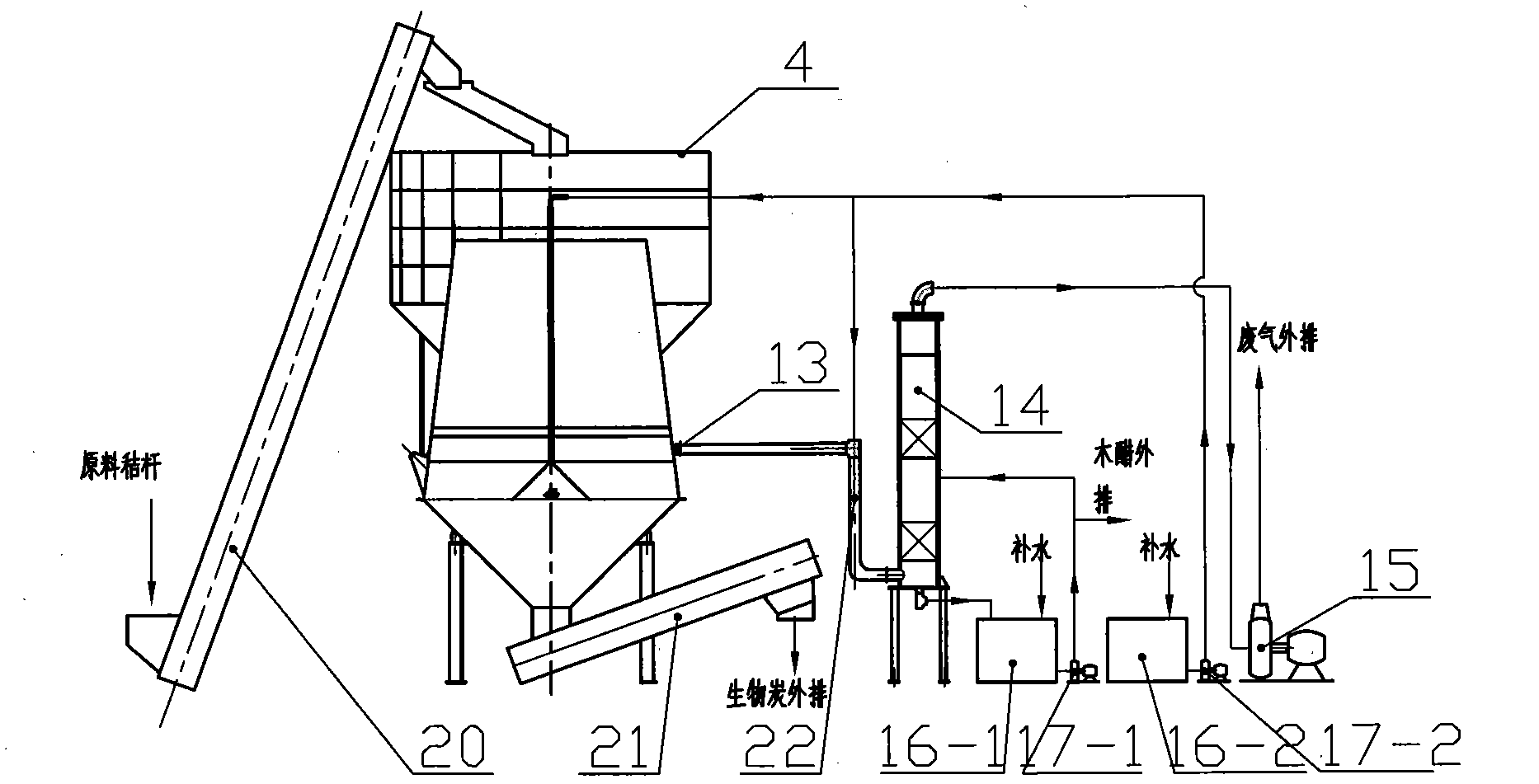

[0038] Start the feeder (20) and load the short joints of straw into the furnace until it is 20-50mm above the air extraction angle box (6) in the furnace, start the air extractor (15), wash the circulating water pump (17-1), spray The circulating water pump (17-2) ignites the uppermost layer of straw with a firelighter. After the combustion is stable, continue to add the raw material straw in batches, and at the same time continuously discharge the material from the discharge machine (21) until the starting non-carbonized straw is discharged. After cleaning and producing finished charcoal, complete the furnace loading and ignition operations;

[0039] 3. Normal operation

[0040] According to the combustion temperature (18) and carbonization temperature (19) in the furnace, adjust the exhaust air volume of the air e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com