Production process of functional health-care wine with abelmoschus manihot

A technology of hollyhock and health wine, applied in the preparation of alcoholic beverages, etc., to achieve the effects of separation and purification, avoiding loss, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

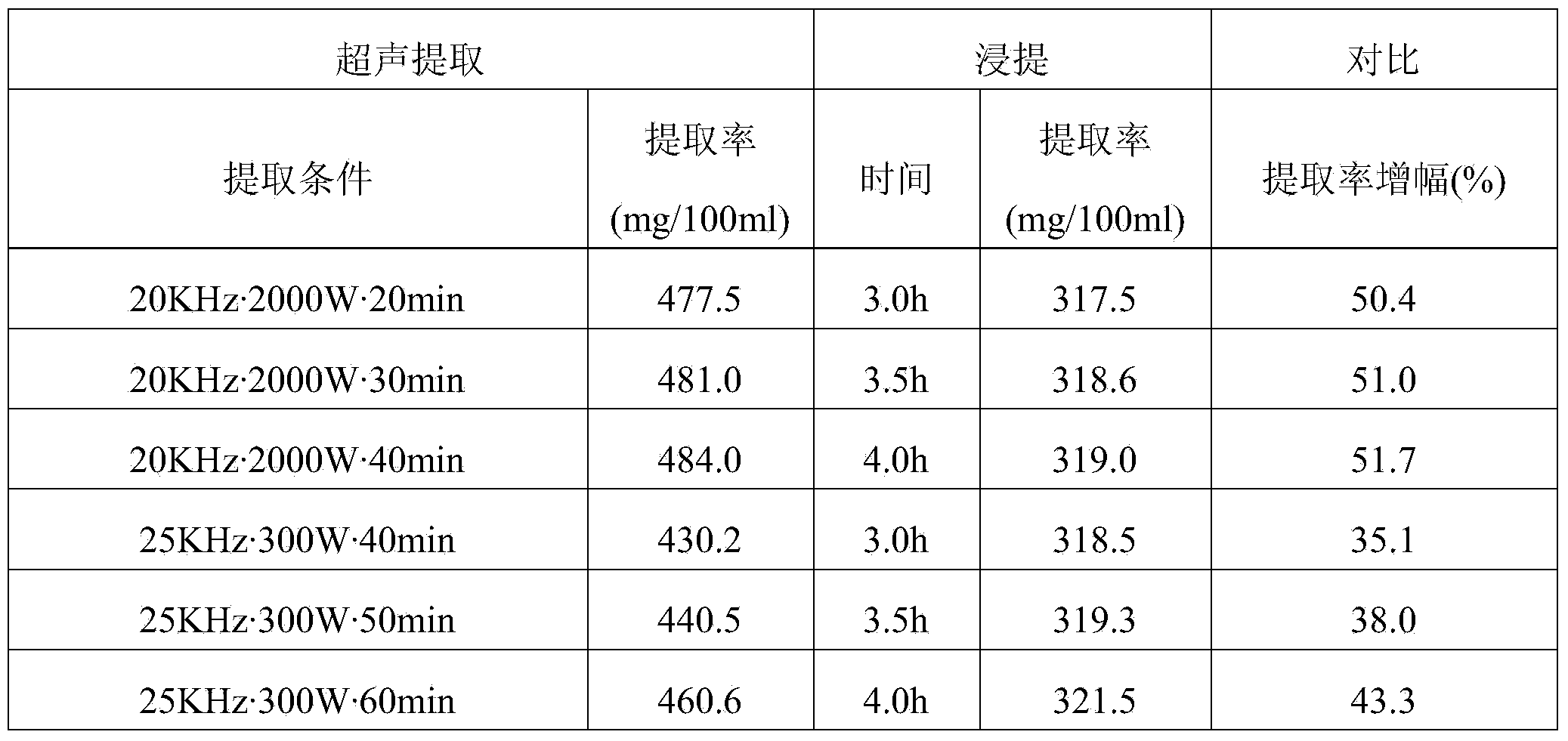

[0056] 1. Remove impurities, wash the hollyhock flowers, flower buds and leaves, put them into a stainless steel mesh sieve to drain the water, cut them into 0.2cm-sized pieces or pieces, put them into a multi-functional extraction tank with an ultrasonic enhancement device, add 50% ethanol, the ratio of solid to liquid is weight ratio, about 1:25, the extraction temperature is 40°C, and the extraction time is 30min; the multifunctional extraction tank is equipped with ultrasonic strengthening and condensation device, which can shorten the extraction time and improve the rate, and the ethanol can be condensed and refluxed for recycling without evaporation loss; the ultrasonic frequency is 20kHz; the power is 2000w; the slag-liquid mixture is obtained.

[0057] 2. The slag liquid mixture obtained in step 1 is passed through a high-speed liquid slag separator to remove the coarse slag, and then through a filter, a filter press, and ultrafiltration to remove small particles and pr...

Embodiment 2

[0067] 1. Remove impurities and wash the hollyhock flowers, flower buds, roots, stems and leaves, put them into a stainless steel mesh sieve to drain the water, cut them into 0.3cm-sized pieces or pieces, and put them into a multi-functional extraction tank with an ultrasonic enhancement device , adding 55% ethanol, the ratio of solid to liquid is the weight ratio, about 1:30, the extraction temperature is 45°C, and the extraction time is 50min. The multi-functional extraction tank is equipped with ultrasonic strengthening and condensing devices, which can shorten the extraction time, increase the yield, and allow the ethanol to be condensed and refluxed for recycling without evaporation loss; the ultrasonic frequency is 20kHz, and the power is 2000w . A slag-liquid mixture is obtained.

[0068] 2. The slag-liquid mixture obtained in step 1 is passed through a high-speed liquid slag separator to remove coarse slag, and then through pressure filtration and ultrafiltration to r...

Embodiment 3

[0078] 1. Remove impurities, wash the hollyhock flowers, flower buds and leaves, put them into a stainless steel mesh sieve to drain the water, cut them into 0.4cm-sized pieces or pieces, put them into a multi-functional extraction tank with an ultrasonic strengthening device, add 60% ethanol, the ratio of solid to liquid is by weight, about 1:28, the extraction temperature is 50°C, and the extraction time is 60 minutes. The multi-functional extraction tank is equipped with ultrasonic strengthening and condensing devices, which can shorten the extraction time, increase the yield, and allow the ethanol to be condensed and refluxed for recycling without evaporation loss; the ultrasonic frequency is 25kHz; the power is 300w ; Obtain the slag-liquid mixture.

[0079] 2. The slag-liquid mixture obtained in step 1 is passed through a high-speed liquid slag separator to remove coarse slag, and then through pressure filtration and ultrafiltration to remove small particles and proteins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com