Production method of black skin steel belt for automobile beam

A production method and technology for automobile beams, applied in the field of producing metal materials, can solve problems such as undiscovered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

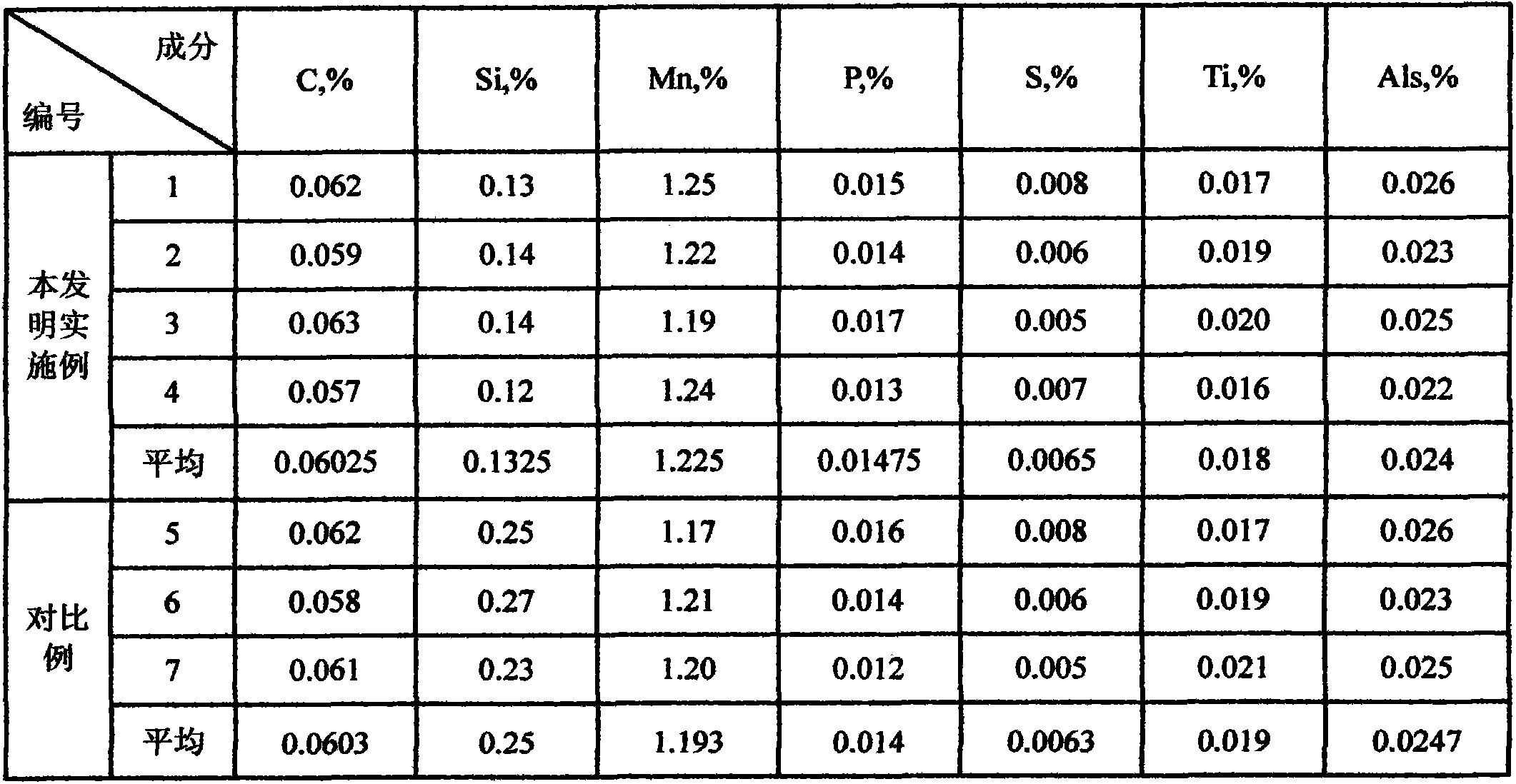

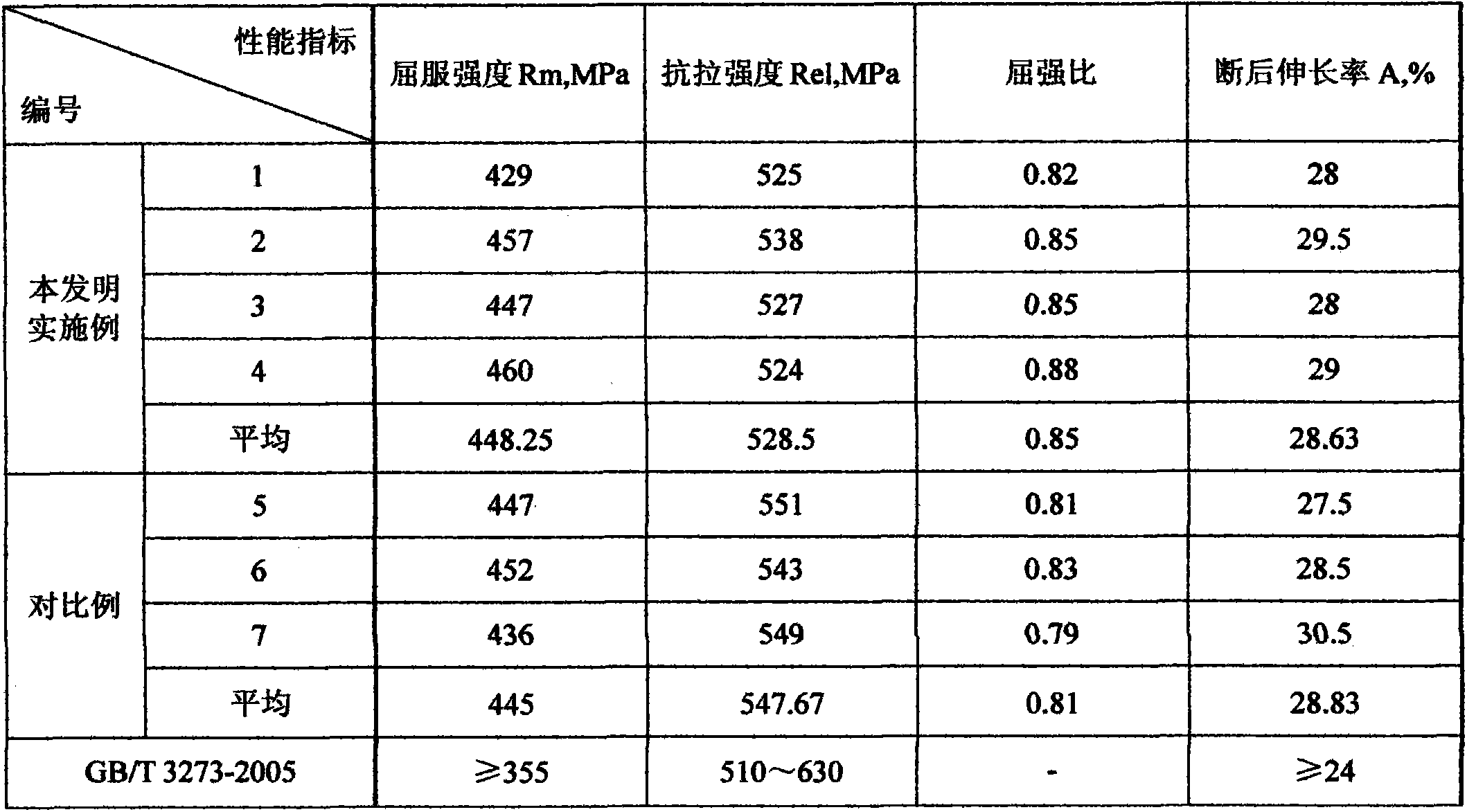

[0033] The chemical composition (wt%) of the black steel strip is: C: 0.04% to 0.07%, Si: ≤0.15%, Mn: 1.10% to 1.30%, P: ≤0.025%, S: ≤0.01%, Nb: 0.020% to 0.030%, Ti: 0.015% to 0.025%, Als: 0.015 to 0.025%, the remainder being Fe and other unavoidable impurities. The present invention adopts top-bottom compound blowing converter + LF refining furnace + thin slab continuous casting and rolling process, and the whole production process is: steelmaking, refining, continuous casting, soaking, hot continuous rolling, laminar cooling, coiling and other processes process.

[0034] 1. The LF refining process precisely controls the content of microalloy elements, the niobium content is controlled at 0.20% to 0.30%, and the titanium content is controlled at 0.015% to 0.025%.

[0035] 2. Carry out deep desulfurization operation in LF furnace to achieve the control target of [S]≤0.008%.

[0036] 3. Control the cooling intensity of the slab by adjusting the cooling water flow rate of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com