Surface treatment method of conductive substrate

A conductive substrate and surface treatment technology, applied in the direction of electrolytic coating, electrophoretic plating, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

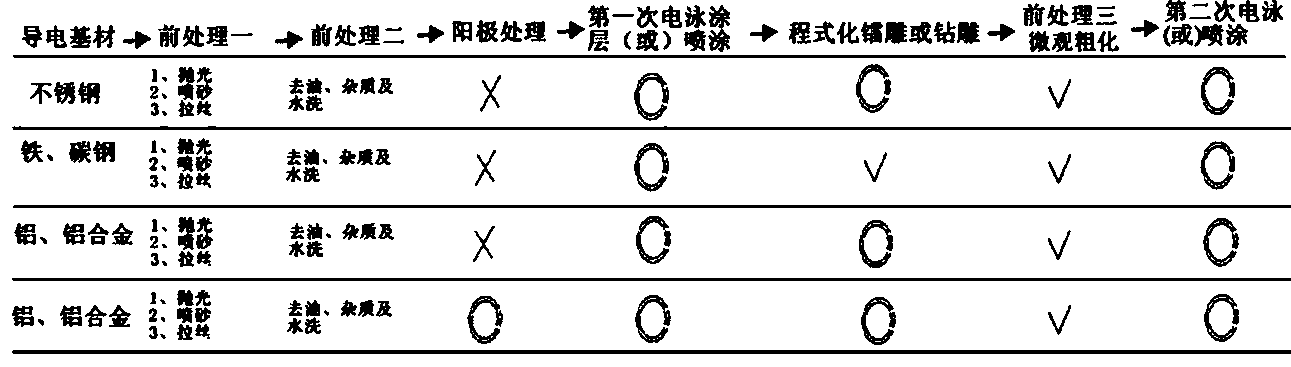

[0063] Please refer to figure 1 As shown, it shows a variety of conductive substrates of the present invention, such as stainless steel, carbon steel, iron, aluminum, aluminum-magnesium alloy and other workpiece surface processes; wherein, the mark X surface does not carry out this step; mark ◎ means this step is ended , it can be a finished product or choose to continue to the next step; record V means that the step is not yet the end, it is not a finished product, and the next step is still needed.

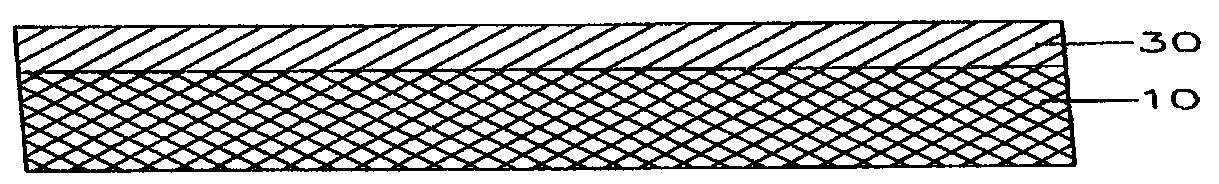

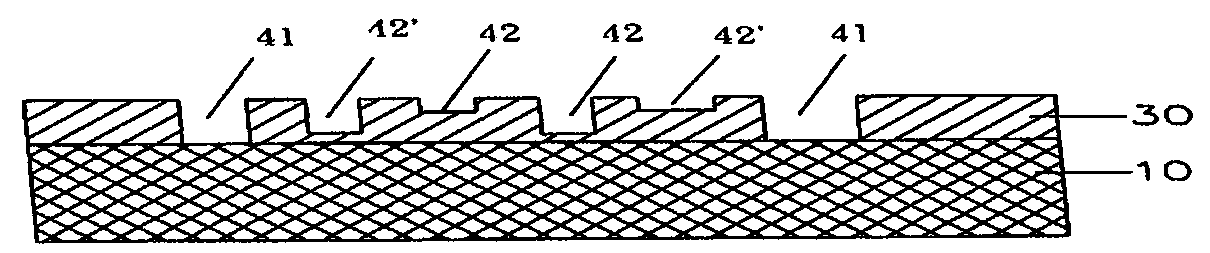

[0064] First of all, conduct the first surface pretreatment on the surface of conductive substrates, such as stainless steel, carbon steel, iron, aluminum, aluminum-magnesium alloys, etc. The first surface pretreatment refers to drawing and sandblasting the surface of the conductive substrate. Or polishing treatment, etc., according to customized requirements. Wire drawing is performed on the surface of the conductive substrate. After electrophoretic coating, it can produce a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com