Method for preparation of calcium magnesium hydrochloride snow-melting agent from two-alkali salt sludge

A technology of calcium magnesium hydrochloride and deicing agent, which is applied in the field of environmental protection and solid waste resource utilization, can solve the problems of environmental pollution, complex components, large output, etc., to reduce production costs, reduce environmental pollution, and reduce disposal The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

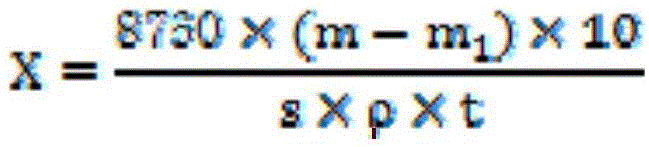

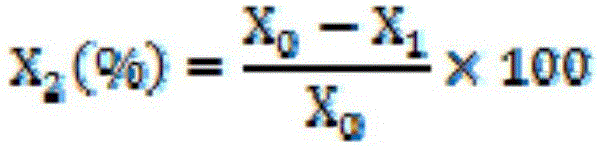

Method used

Image

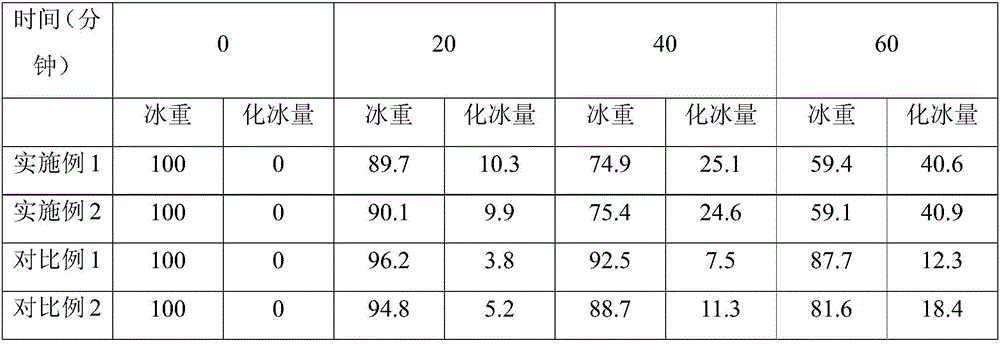

Examples

Embodiment 1

[0021] The composition of the two-alkali salt mud used in the present embodiment is calculated as CaCO in parts by weight. 3 87.2 parts, NaCl1.2 parts, Mg(OH) 2 8.5 parts, CaSO 4 1.6 parts, Fe(OH) 3 0.5 part, Al(OH) 3 0.8 parts, SiO 2 0.2 parts,

[0022] (1) will contain 500g CaCO 3 The above-mentioned two-alkali salt mud is stirred and dispersed into a slurry in 500mL water at normal temperature (25°C), and then waste hydrochloric acid (HCl mass fraction is 29%, and the rest of the components do not participate in the reaction) is added dropwise to the slurry under stirring until No bubbles appear in the reaction system;

[0023] (2) Filtrating the reaction system obtained in step (1), and concentrating the resulting filtrate under reduced pressure at 0.06Mpa and 140°C;

[0024] (3) Transfer the concentrated solution obtained in step (2) to a fluidized bed spray granulation dryer for drying and granulation to obtain an environmentally friendly deicing agent with a...

Embodiment 2

[0026] The composition of the two-alkali salt mud used in the present embodiment is calculated as CaCO in parts by weight. 3 87.2 parts, NaCl1.2 parts, Mg(OH) 2 8.5 parts, CaSO 4 1.6 parts, Fe(OH) 3 0.5 part, Al(OH) 3 0.8 parts, SiO 2 0.2 parts,

[0027] (1) will contain 500g CaCO 3 The above-mentioned two-alkali salt mud is stirred and dispersed into a slurry in 500 mL of water at room temperature (25° C.), and then in the slurry under stirring, waste hydrochloric acid (HCl mass fraction is 29%, and the rest of the components do not participate in the reaction) is added dropwise to the slurry until No bubbles appear in the reaction system;

[0028] (2) Filtrating the reaction system obtained in step (1), and concentrating the resulting filtrate under reduced pressure at 0.06Mpa and 140°C;

[0029] (3) Combine the concentrate obtained in step (2) with the corrosion inhibitor (the corrosion inhibitor components are zinc dihydrogen phosphate and sodium lignosulfonate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com