A composite pipe and its manufacturing method

A technology for composite pipes and base pipes, applied in the field of rubber and plastic manufacturing and processing, can solve the problems of large bending radius, medium penetration, high cost, etc., and achieve the effects of simple manufacturing method, alleviating environmental pressure, and solving environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

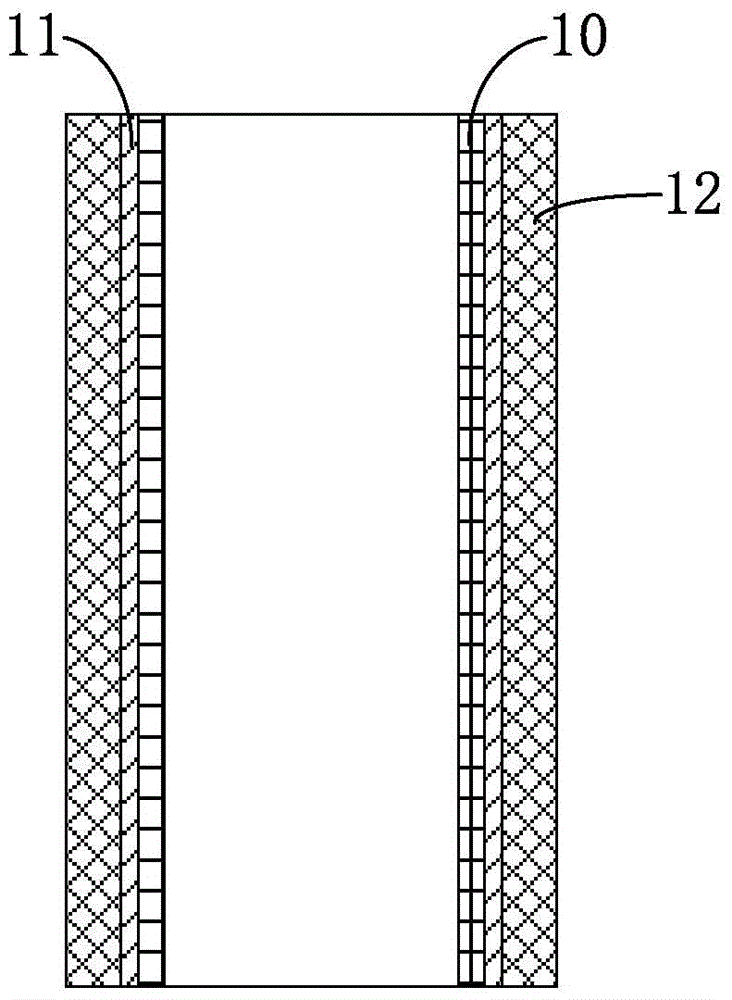

[0028] Provide a kind of composite pipe material in this embodiment, its structure is as figure 1 shown.

[0029] In this embodiment, the composite pipe material uses TPU as the base pipe 10, the barrier layer 11 is fluorinated HDPE, and the covering layer 13 is TPU. The specific manufacturing method is as follows:

[0030] (1) A pipe with an inner diameter of 1.6mm and a thickness of 0.5mm is extruded through a double-die extrusion process, wherein the inner layer is made of TPU base material tube 10, the thickness of the base material tube is 0.4mm, and the outer layer is coated with 0.1 HDPE layer of mm thickness;

[0031] (2) Carry out fluorination treatment to the pipe material of step (1), the fluorine gas concentration is 5%, carry out fluorination reaction at 40 ℃, the fluorination reaction time is 1.5 hours, and the fluorination pressure is 0.05MPa, and the outer surface has A composite pipe with a barrier layer 11;

[0032] (3) Cover the outer surface of the comp...

Embodiment 2

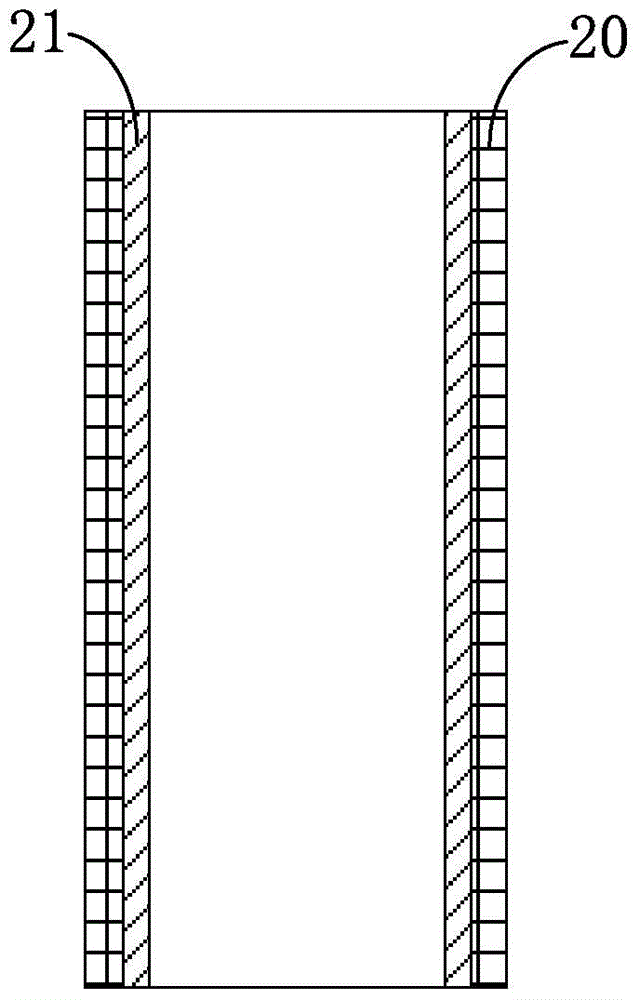

[0042] Provide a kind of composite pipe material in this embodiment, its structure is as figure 2 shown.

[0043] In this embodiment, the composite pipe material uses PVC as the base pipe 20, and the barrier layer 21 is fluorinated HDPE. The specific manufacturing method is as follows:

[0044] (1) Extruding an inner diameter of 2.5 mm through a double-die extrusion process and a double-layer pipe with an outer diameter of 5 mm, wherein the outer layer is a PVC substrate pipe 20, and the inner surface is a HDPE layer with a thickness of 0.1 mm;

[0045] (2) Put the pipe material of step (1) into the fluorination furnace, carry out fluorination treatment, the fluorine gas concentration is 5%, carry out fluorination reaction at 30 ℃, the fluorination reaction time is 2 hours, the fluorination pressure is 0.05 MPa to obtain a composite pipe with a barrier layer 21 on the inner surface.

[0046] The composite pipe in this embodiment maintains the good tensile properties, trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com