Optical detection sensor for microcystin

A microcystin and optical detection technology, which is applied in the measurement of color/spectral characteristics and phase influence characteristics, can solve the problems of inability to identify toxins and false positive reactions, and achieve improved sensitivity, low requirements, and Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

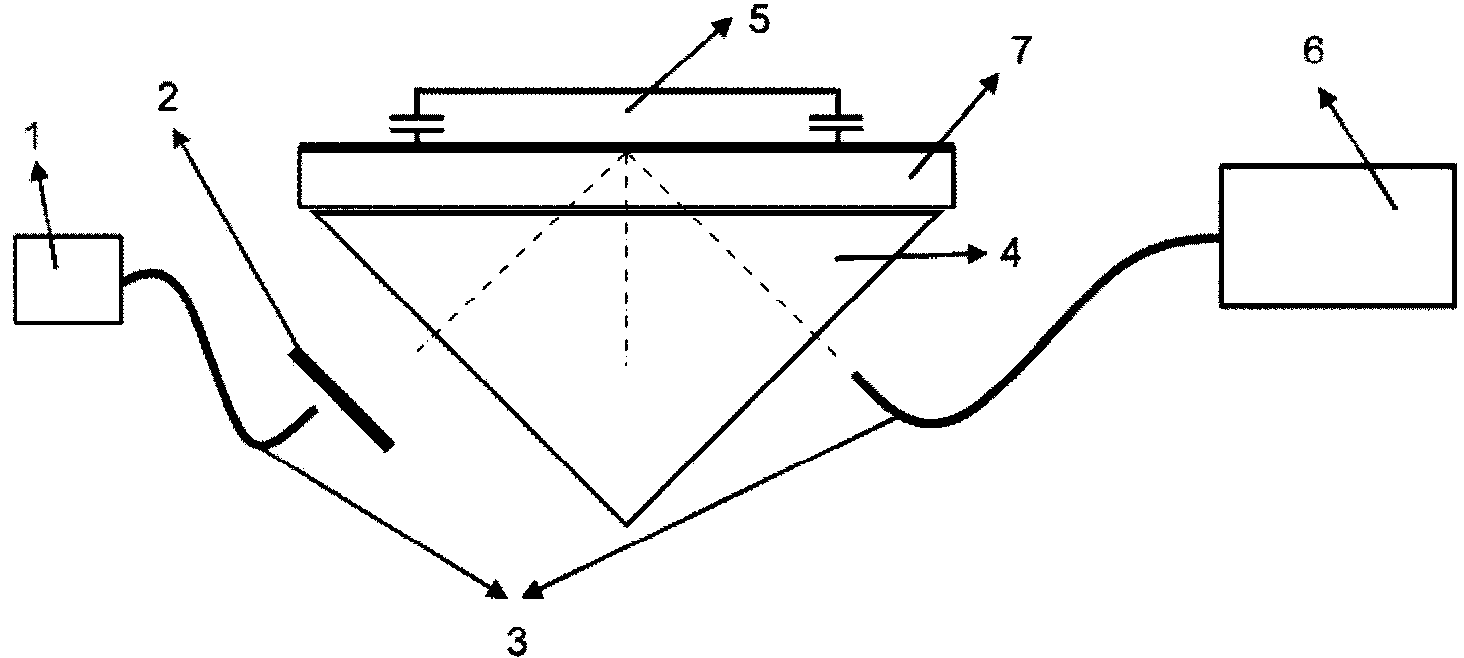

Method used

Image

Examples

Embodiment 1

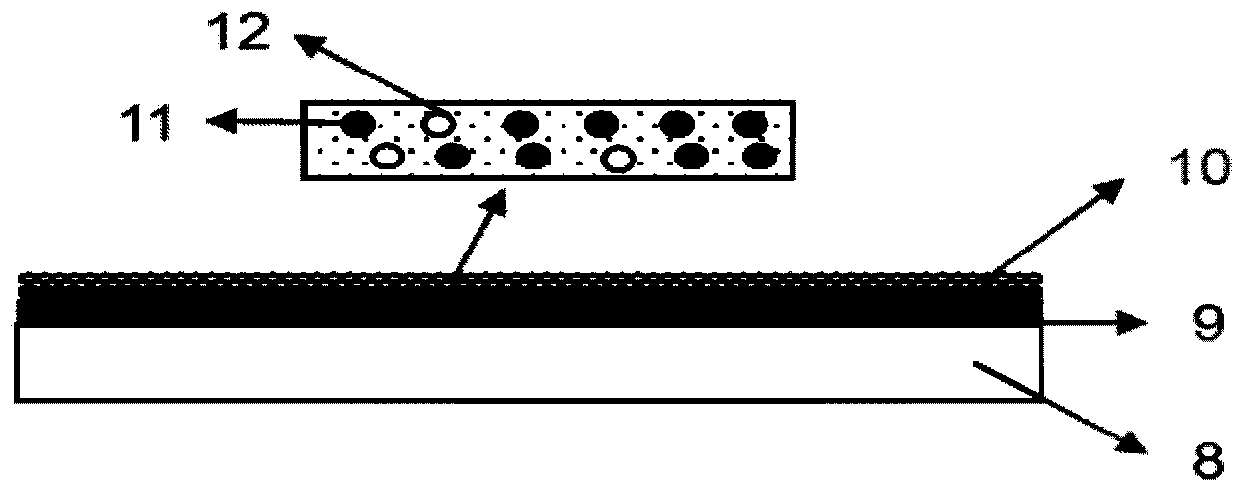

[0024] Modified on the surface of the gold layer by thermal polymerization microcystin molecularly imprinted membrane: clean the gold-plated glass sheet with an oxygen plasma cleaner for 2 minutes, soak it in an ethanol solution of 50mM undecylthiolanic acid for more than 12 hours, take it out Rinse with ethanol, blow dry with nitrogen; then immerse in a mixed aqueous solution of 0.1M 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 0.01M N-hydroxysuccinimide 1 hour; take it out and immerse it directly in 100mM aminobutyramide hydrochloride aqueous solution for 3 hours, blow dry with nitrogen; take 0.1umol microcystin, 1umol methacrylic acid and 2umol trimethylolpropane trimethacrylate and add 5mL dimethicone Mix the methyl sulfoxide solution, treat with nitrogen for 10 minutes, immerse the pretreated glass sheet, and conduct thermal polymerization reaction at 65±5°C for 18 hours after sealing; after taking it out, use a mixed solution of ethanol and acetic acid ...

Embodiment 2

[0026] Modified on the surface of the gold layer by thermal polymerization microcystin molecularly imprinted membrane: clean the gold-plated glass sheet with an oxygen plasma cleaner for 4 minutes, soak it in an ethanol solution of 1000mM undecaptanic acid for more than 12 hours, and take it out Rinse with ethanol, blow dry with nitrogen; then immerse in a mixed aqueous solution of 1M 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 0.1M N-hydroxysuccinimide 1 After taking it out, immerse it directly in 500mM aminobutyramide hydrochloride aqueous solution for 3 hours, blow dry with nitrogen; take 200umol microcystin, 2000umol methacrylic acid and 2000umol trimethylolpropane trimethacrylate and add 10mL dimethyl Mix the sulfoxide solution, treat with nitrogen for 12 minutes, immerse in the pretreated glass sheet, and conduct thermal polymerization reaction at 65±5°C for 15 hours after sealing; after taking it out, use a mixed solution of ethanol and acetic acid in...

Embodiment 3

[0028]Modified on the surface of the gold layer by thermal polymerization microcystin molecularly imprinted membrane: clean the gold-plated glass sheet with an oxygen plasma cleaner for 3 minutes, soak it in an ethanol solution of 200mM undecaptanic acid for more than 12 hours, take it out Rinse with ethanol, blow dry with nitrogen; then immerse in a mixed aqueous solution of 0.2M 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 0.05M N-hydroxysuccinimide 1 hour; take it out and immerse it directly in 200mM aminobutyramide hydrochloride aqueous solution for 3 hours, blow dry with nitrogen; take 100umol microcystin, 200umol methacrylic acid and 300umol trimethylolpropane trimethacrylate and add 6mL dimethyl Mix the base sulfoxide solution, treat with nitrogen for 13 minutes, immerse in the pretreated glass sheet, and conduct thermal polymerization reaction at 65±5°C for 20 hours after sealing; after taking it out, use a mixed solution of ethanol and acetic acid in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com